Multifunctional testing system for suppressing explosion of flammable gas by water mist and testing method implementing same

A technology of gas explosion and test system, which is applied in the direction of material explosion, can solve the problems of easy deviation of test result accuracy, high manufacturing and operation level requirements, and inability to flexibly combine and replace, achieving significant social and economic benefits, manufacturing Low cost, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

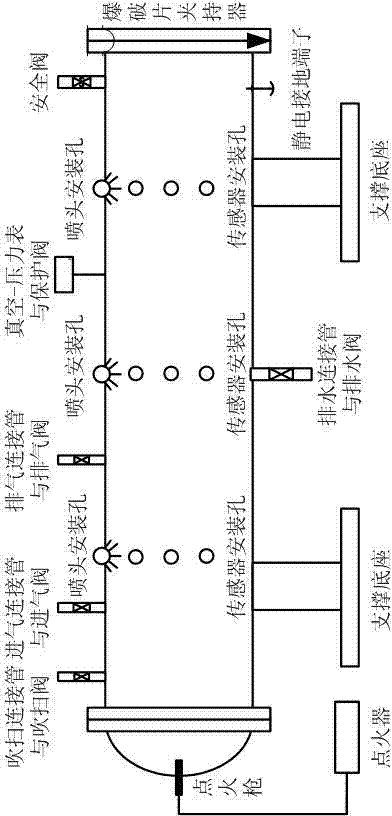

[0009] Referring to the accompanying drawings, the multifunctional water mist suppression combustible gas explosion test system is composed of a main part of the equipment, a data acquisition part and an accessory part; the data acquisition part and the accessory part are installed on the test pipe in the main part of the equipment.

[0010] The main part of the equipment is composed of a test pipe, a head and its supporting ignition device, a bursting disc holder and a bursting disc; one end of the test pipe is equipped with a head, and the head is connected with the matching ignition device, and the test pipe is The other end is connected to the bursting disc holder through flanges and bolts to hold the bursting disc.

[0011] The inner diameter of the test pipeline is 377mm and the length is 2000mm. The two ends of the test pipeline are provided with connecting flanges for connecting the head and the bursting disc holder. There are 3 nozzle installation wire holes (respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com