Rake-type exploring process method of deep mineral resource

A technology of mineral resources and process methods, applied in the field of exploration and coring, can solve the problems of increased input costs, increased drilling costs, and reduced effects of vertical drilling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

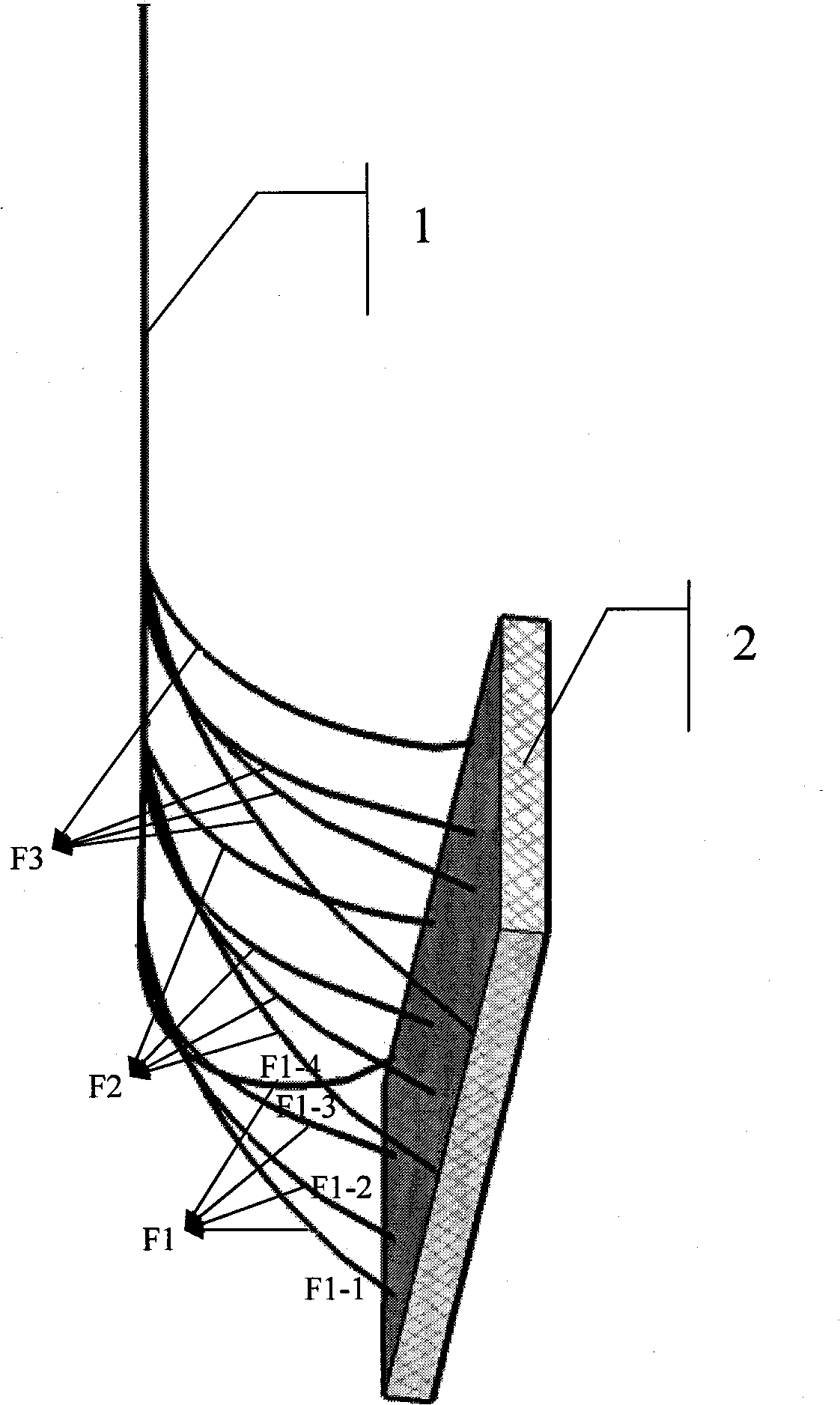

[0010] The implementation steps of this method are as follows:

[0011] (1) Determine the target point and target area where the mother hole is scheduled to reach the target layer, and design the drilling position and depth of the mother hole, the position of the kickoff point and each The direction and drilling depth of the branch hole. There are two design methods: drawing method and calculation method, and there is no substantial difference between the two.

[0012] (2) Drilling of the parent hole (ie the main well hole): After the hole is opened, technical casing is installed and cemented, and then drilling is continued until the drilling of the parent well is completed. The process is no different from conventional drilling.

[0013] (3) After the drilling of the mother hole is completed, start drilling each branch hole. During branch hole drilling, build-up points should be reasonably selected, the installation angle of the build-up tool should be calculated, the build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com