Method for calculating rotor dynamics performance of multi-parallel-axis system

A technology of rotor dynamics and calculation methods, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as can not guarantee normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

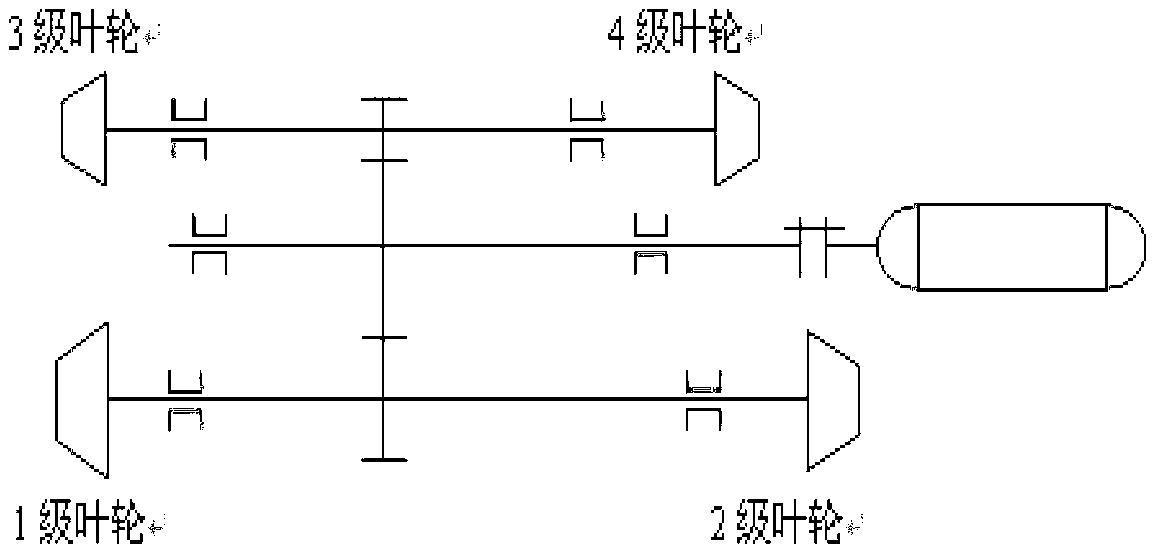

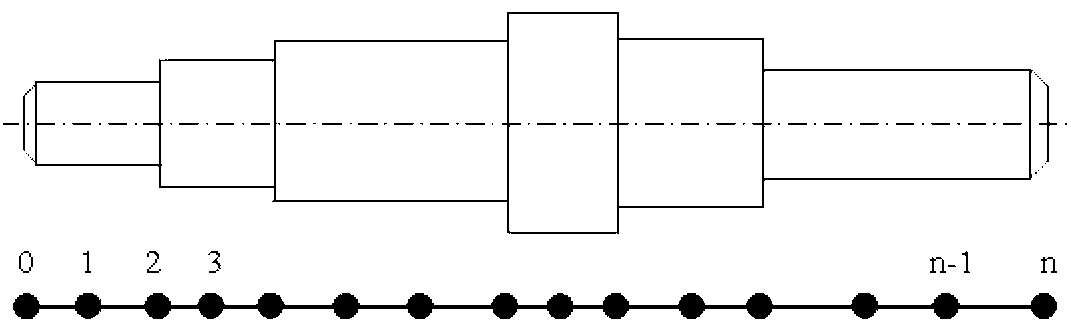

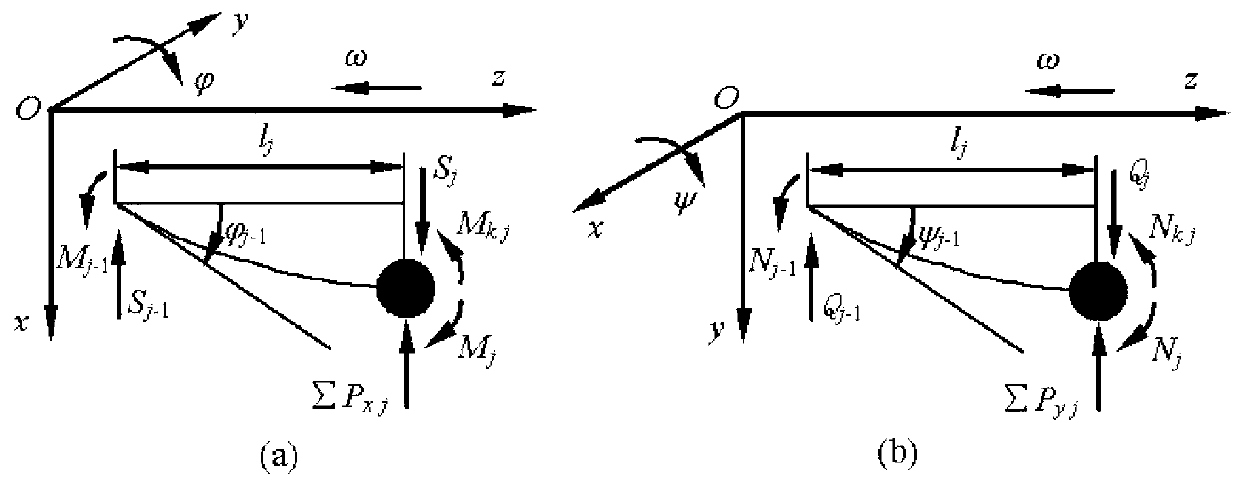

[0030] The method for calculating the rotor dynamic performance of the present invention comprises the following steps:

[0031] 1) Pre-processing for dynamic analysis of multi-parallel axis system:

[0032] ①Choose calculation objects among compressors, speed reducers, speed increasers, etc., select eigenvalues and forced vibration response calculations or critical speed and instability speed calculations, and at the same time, choose multi-parallel shaft system analysis considering gear coupling or one of them A rotor analysis.

[0033] ② Input the parameters of each rotor and bearing in the system: including shaft section parameters, additional quality parameters, unbalanced quality parameters, gear parameters and bearing type, position and dynamic characteristic coefficients, etc.

[0034] If the eigenvalue and mode shape analysis and unbalanced response analysis at a certain speed are carried out, the speed of the drive shaft (coupling system analysis) or the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com