Negative pole material of lithium ion battery, preparation method of material and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as electrode structure instability, negative electrode material structure collapse, and complex preparation processes, so as to improve electrical conductivity, good cycle performance, The effect of high capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0038] Mix the tin dioxide hydrosol with the ethyl orthosilicate absolute ethanol solution, adjust the pH value to 10-13 after 0.5h-2h, and obtain tin dioxide nanoparticles coated with silicon dioxide;

[0039]Mixing the tin dioxide nanoparticles coated with silicon dioxide with an anhydrous ethanol solution containing a coupling agent and a titanium compound, aging for 1h~6h, and obtaining a precipitate after 5h~10h;

[0040] The precipitate is washed with hydrofluoric acid to obtain the washed precipitate;

[0041] The washed precipitate is mixed with graphene, dried and annealed to obtain the lithium ion battery negative electrode material.

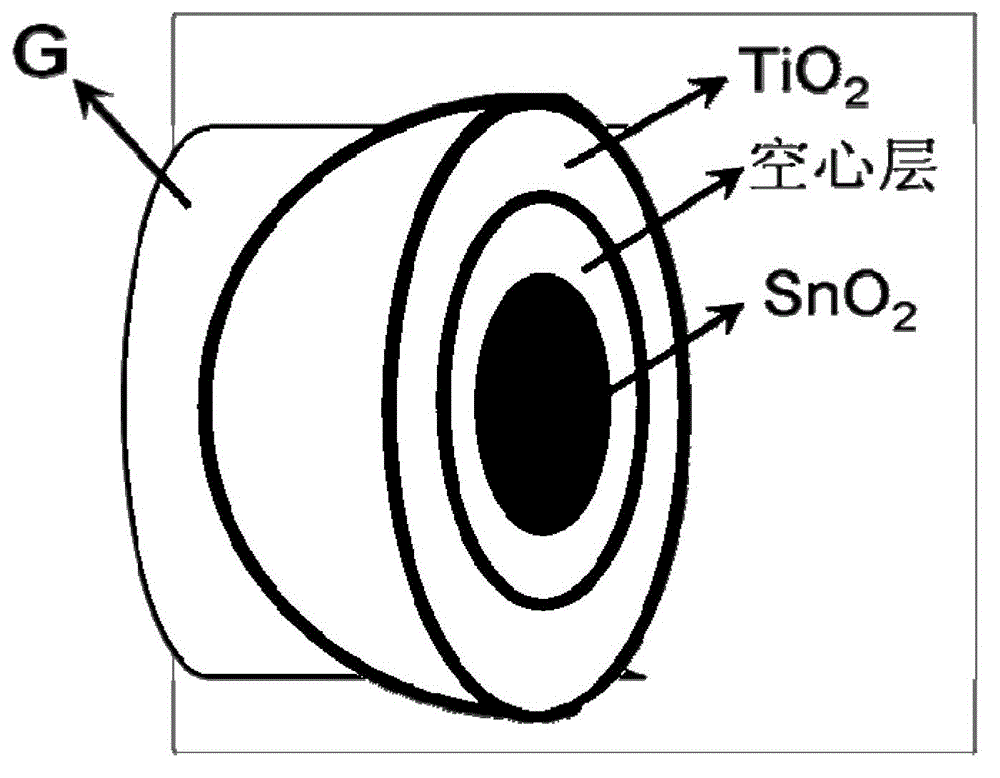

[0042] The present invention utilizes the high-capacity performance of tin dioxide, the morphological stability performance of titanium dioxide, the conductivity performance of graphene, etc.,...

Embodiment 1

[0069] Dissolve 2g of stannous chloride in 300mL of absolute ethanol, stir well to obtain stannous chloride in absolute ethanol; slowly drop 100mL of glacial acetic acid solution with a pH value of 4.5 into the stannous chloride in absolute ethanol Carry out reaction, stir 3h, obtain tin dioxide hydrosol;

[0070] Add a 5% tetraethyl orthosilicate absolute ethanol solution dropwise into the tin dioxide hydrosol, stir for 0.5 h and then adjust the pH value to 10 to obtain tin dioxide nanoparticles coated with silicon dioxide ;

[0071] Drop 8mL KH550 into 100mL of absolute ethanol, and then add 1mL of tetrabutyl titanate to it to obtain an absolute ethanol solution containing KH550 and tetrabutyl titanate, which is dropped into the silicon dioxide-coated In the tin oxide nanoparticles, after vigorously stirring for 5 hours, aging was carried out at room temperature, and a precipitate was obtained after 10 hours;

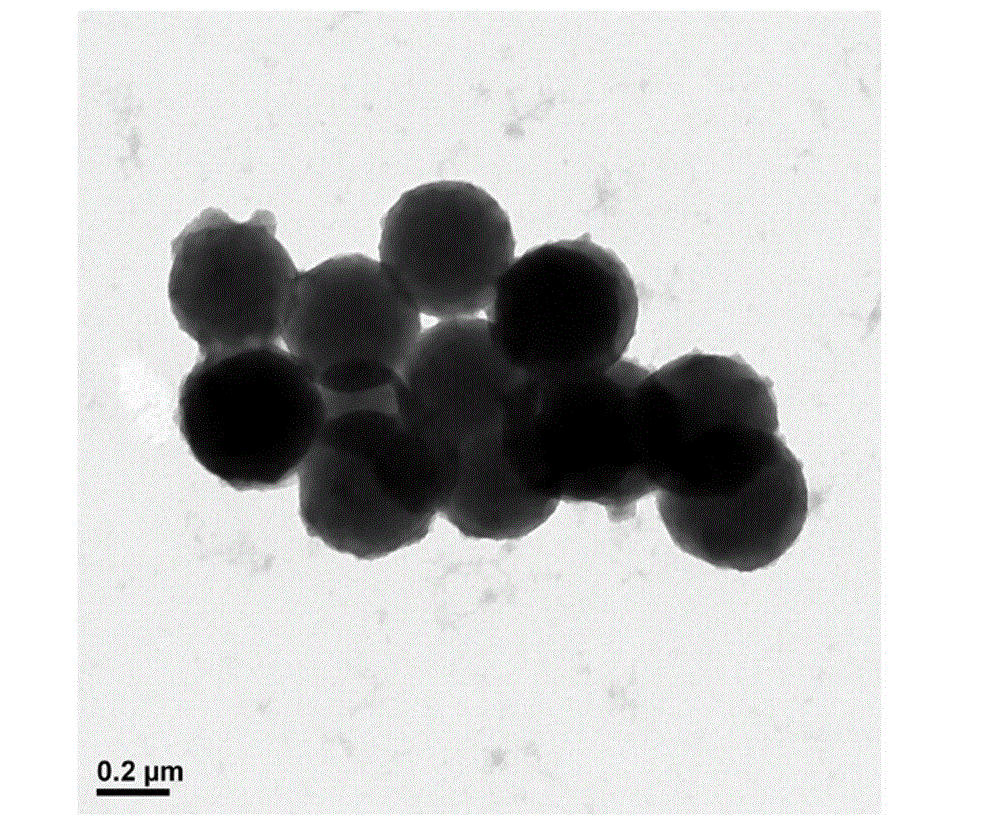

[0072] Described precipitate is carried out transmission elect...

Embodiment 2

[0080] Dissolve 2g of stannous chloride in 400mL of absolute ethanol, stir well to obtain stannous chloride in absolute ethanol; slowly drop 100mL of glacial acetic acid solution with a pH value of 1 into the stannous chloride in absolute ethanol Carry out reaction, stir 3h, obtain tin dioxide hydrosol;

[0081] Adding an absolute ethanol solution of tetraethyl orthosilicate with a mass concentration of 10% into the tin dioxide hydrosol, stirring for 2 hours and adjusting the pH value to 12 to obtain tin dioxide nanoparticles coated with silicon dioxide;

[0082] Add 8 mL of KH570 dropwise into 100 mL of absolute ethanol, and then add 1 mL of tetrabutyl titanate to it to obtain an absolute ethanol solution containing KH570 and tetrabutyl titanate, which is dropped into the silicon dioxide-coated In the tin oxide nanoparticles, after vigorously stirring for 5 hours, aging was carried out at room temperature, and a precipitate was obtained after 10 hours;

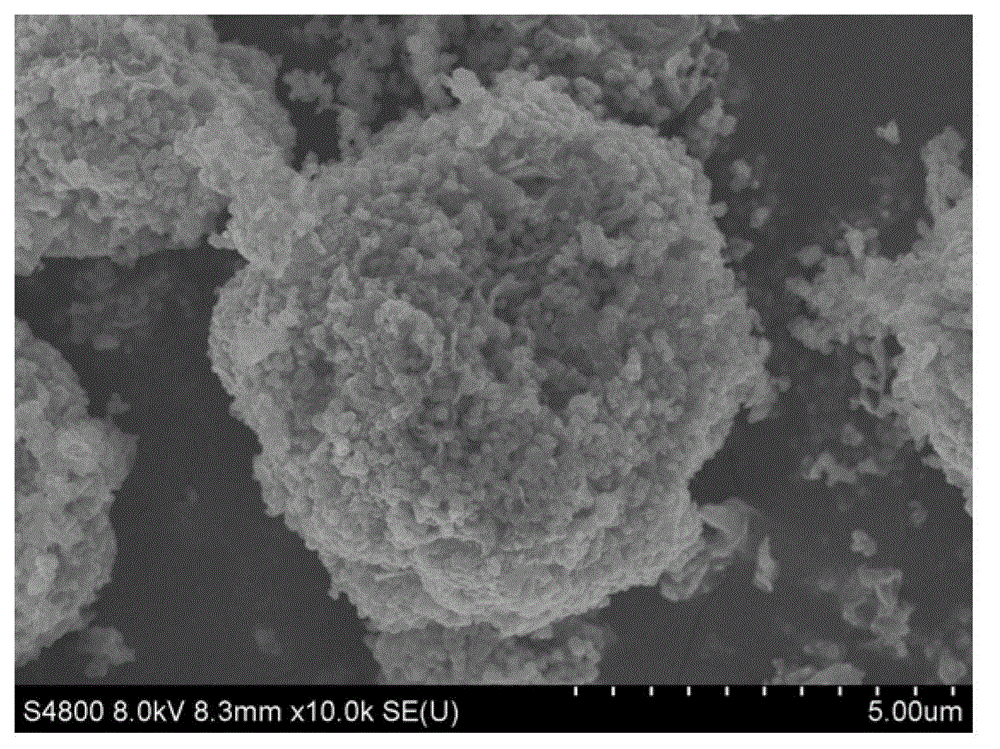

[0083] The precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com