Method and apparatus for measuring the concentration of component in inspection liquid used for wet-type fluorescent magnetic particle testing

A fluorescent magnetic powder and concentration measurement technology, which is applied in the direction of fluorescence/phosphorescence, optical test flaw/defect, color/spectral characteristic measurement, etc., can solve the problem of weakening anti-rust effect and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

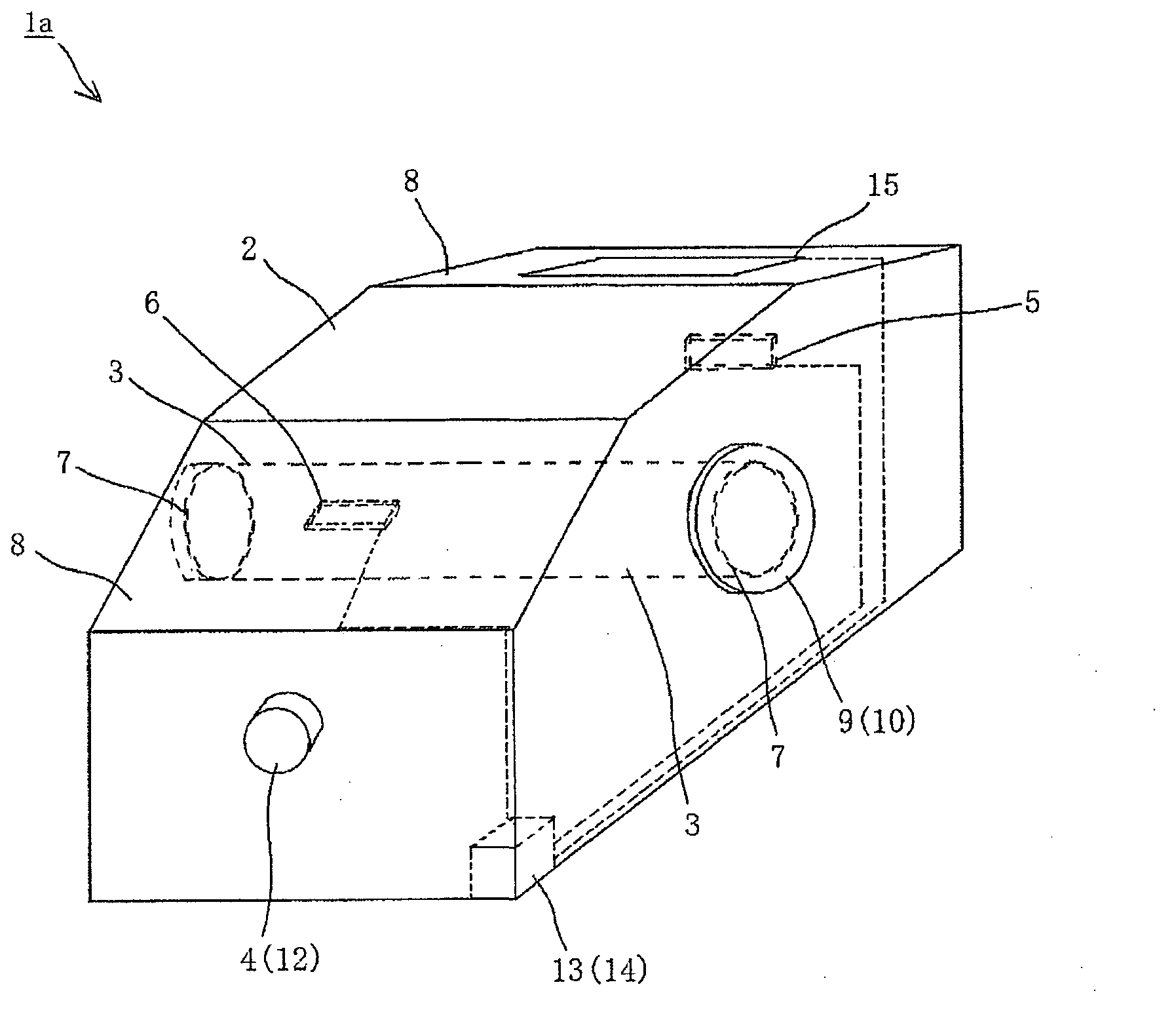

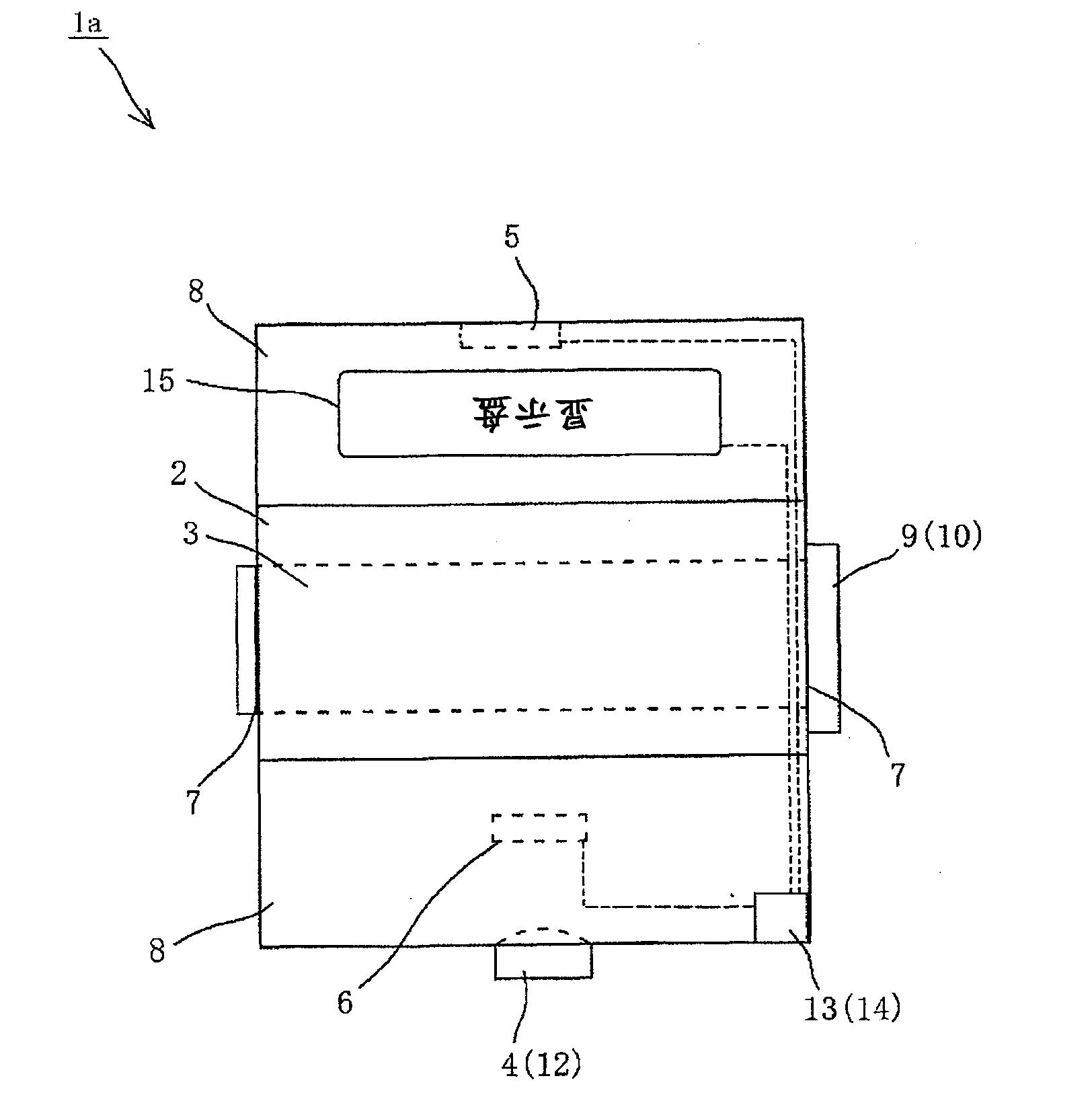

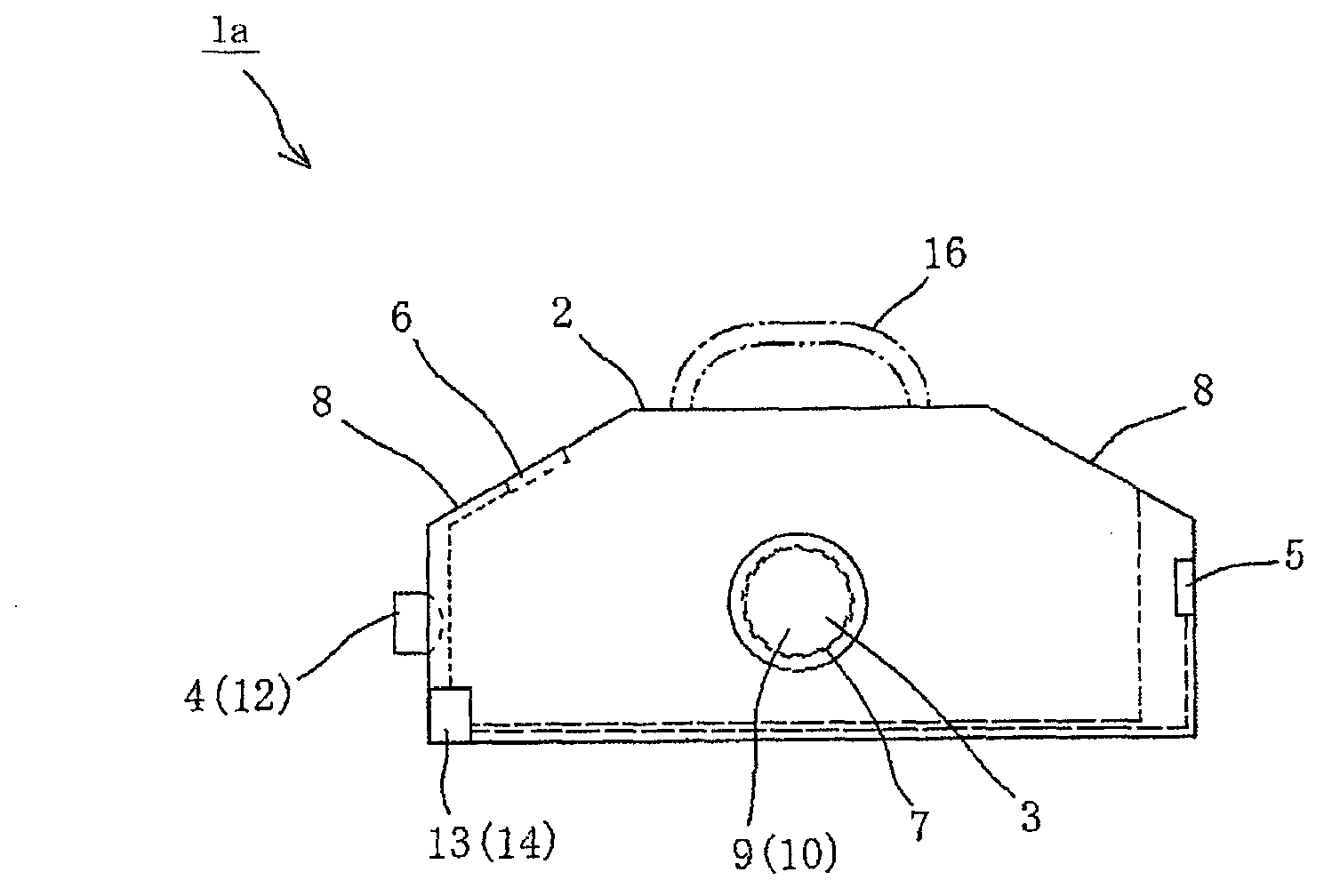

[0060] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings. First, as known, the inspection liquid used in the wet fluorescent magnetic particle flaw detection test is prepared by mixing fluorescent magnetic powder, a dispersant, and if necessary, a rust inhibitor.

[0061] Then, the details of these components are, for example, in the above-mentioned JP-A-2009-109424, or as described in JP-A-2009-109424, etc., as the fluorescent magnetic powder, for example, commercially available magnetic powder (in the form of ferric oxide particles Or magnetically conductive particles such as pure iron particles use synthetic resin binders such as cellulose acetate-based synthetic resins or polyvinyl butyral-based synthetic resins, and attach Lumargen Yellow 50790 (trade name), produced by BASF, Median diameter 3~70μm formed with fluorescent pigments such as Festa A (trade name) and Swada Co., Ltd.: Displayed based on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com