Hydraulic press special for integral compound bulging of automatic driving axle

A technology for hydraulic presses and drive axles, applied in the field of hydraulic presses, can solve the problems of difficulty in controlling forming flow, uneven width of flanging at the pipa bag, high utilization rate of blanks, and high comprehensive mechanical properties of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

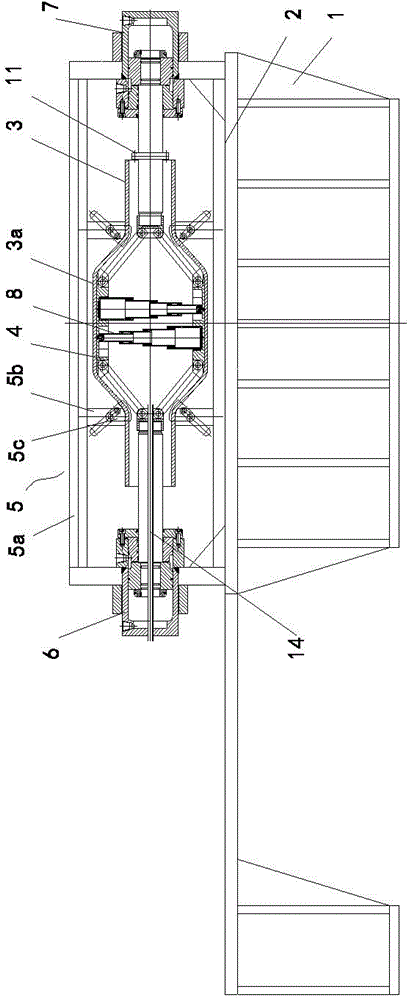

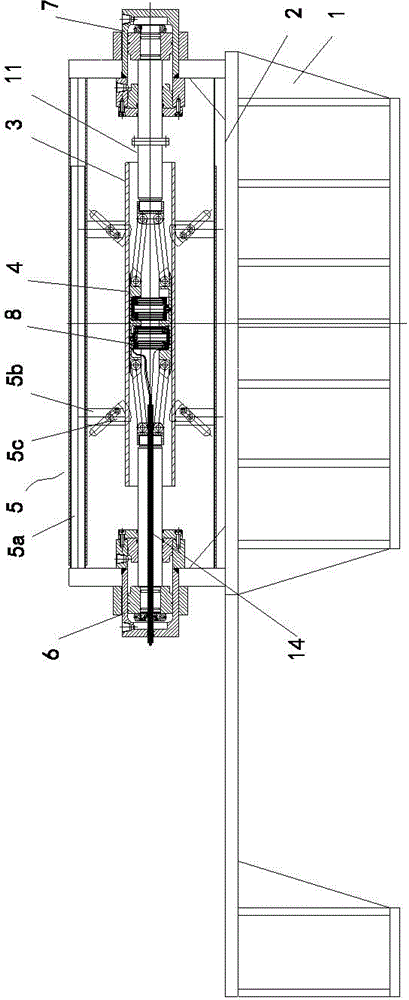

[0060] Such as figure 1 As shown, it is a schematic diagram of the structure of the special hydraulic press for integral compound bulging of the automobile drive axle of the present invention before the bulging deformation of the axle housing workpiece; figure 2 It is a structural schematic diagram of the special hydraulic press for overall compound bulging of the automobile drive axle after the bulging deformation of the axle housing workpiece of the present invention.

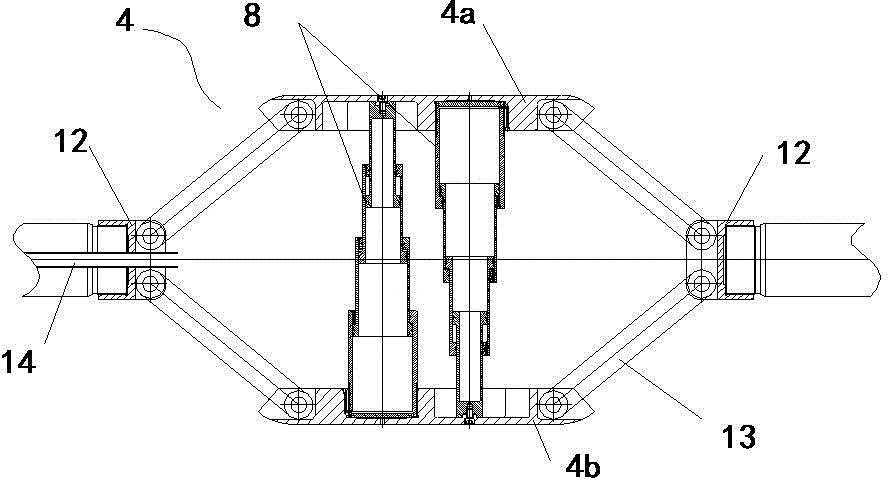

[0061] The special-purpose hydraulic press for integral composite bulging of the automobile drive axle of the present embodiment includes a hydraulic press body and a hydraulic bulging system; the hydraulic press body includes a frame 1 provided with a workbench 2, on which a bulging machine for the axle housing workpiece 3 is installed. The bulging inner mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com