Control method for detection of slab in heating furnace

A control method and heating furnace technology, applied in heat treatment furnaces, electrical program control, program control in sequence/logic controllers, etc., can solve problems such as falling into the furnace, bumping into the discharge furnace door, and dropping of horns, etc. problems, to improve production efficiency and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Implemented on Baosteel's wide and thick plate heating furnace, the specific implementation process is as follows:

[0060] (1) In the preparation for tapping, the operator tracks the slab thickness information according to the production plan.

[0061] (2) Select "120mm thickness mode control" on the operation screen and input "120MM" on the "thickness control setting" on the operation screen, and the PLC receives the thickness setting.

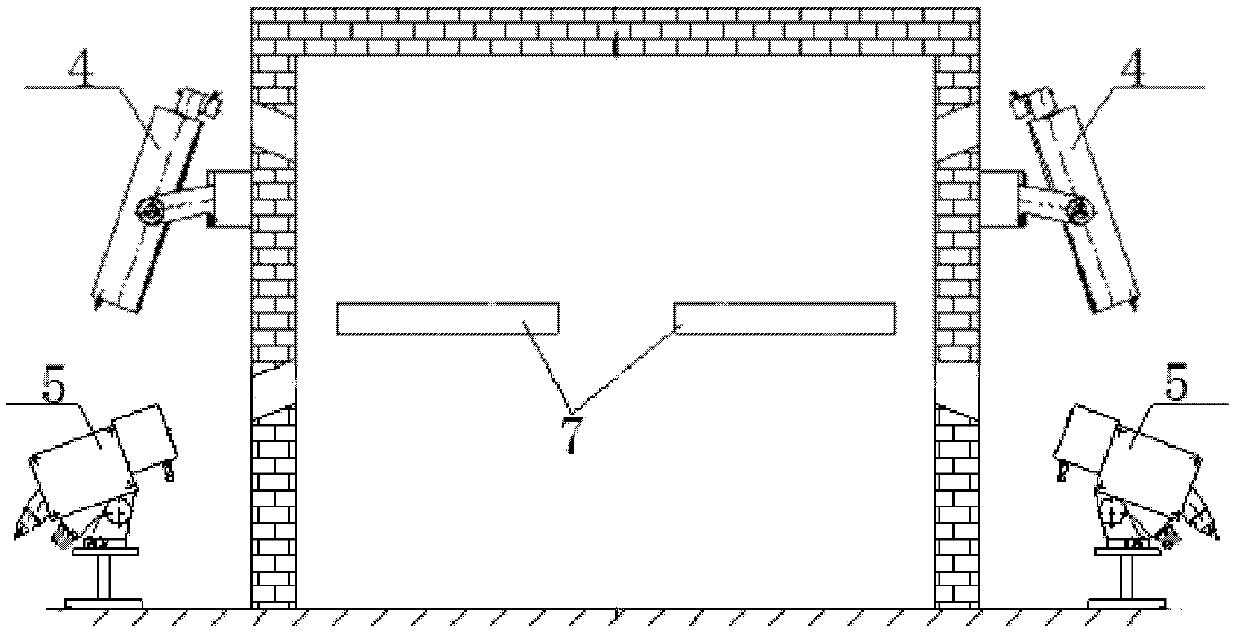

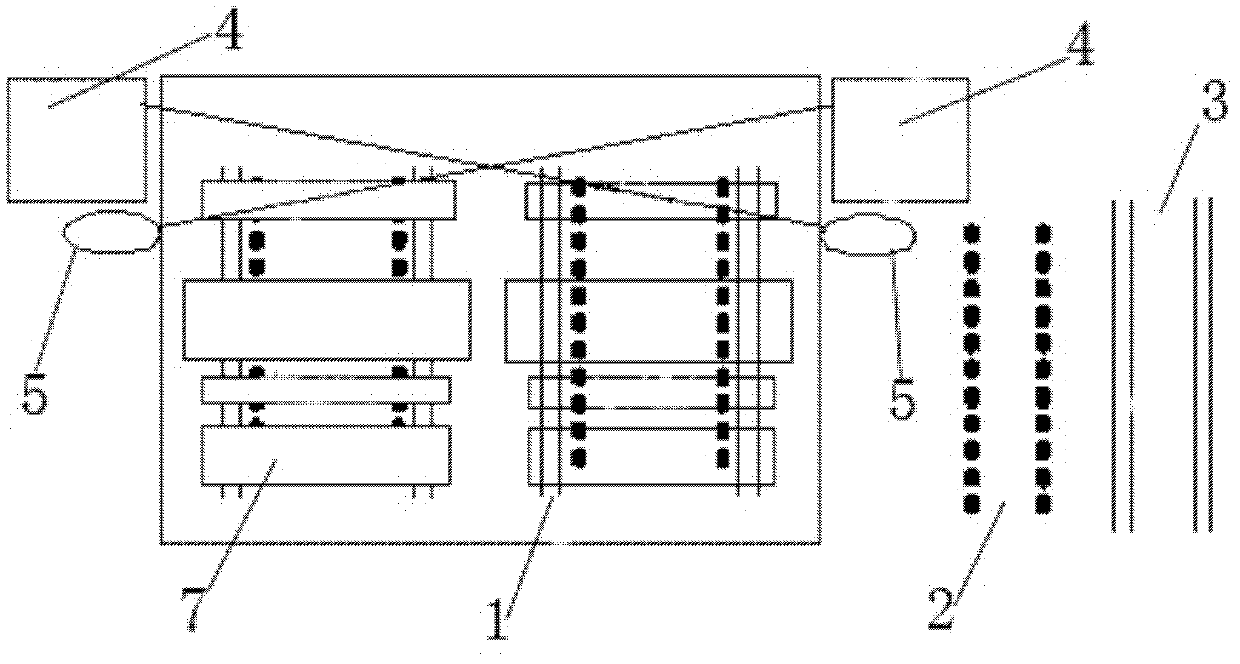

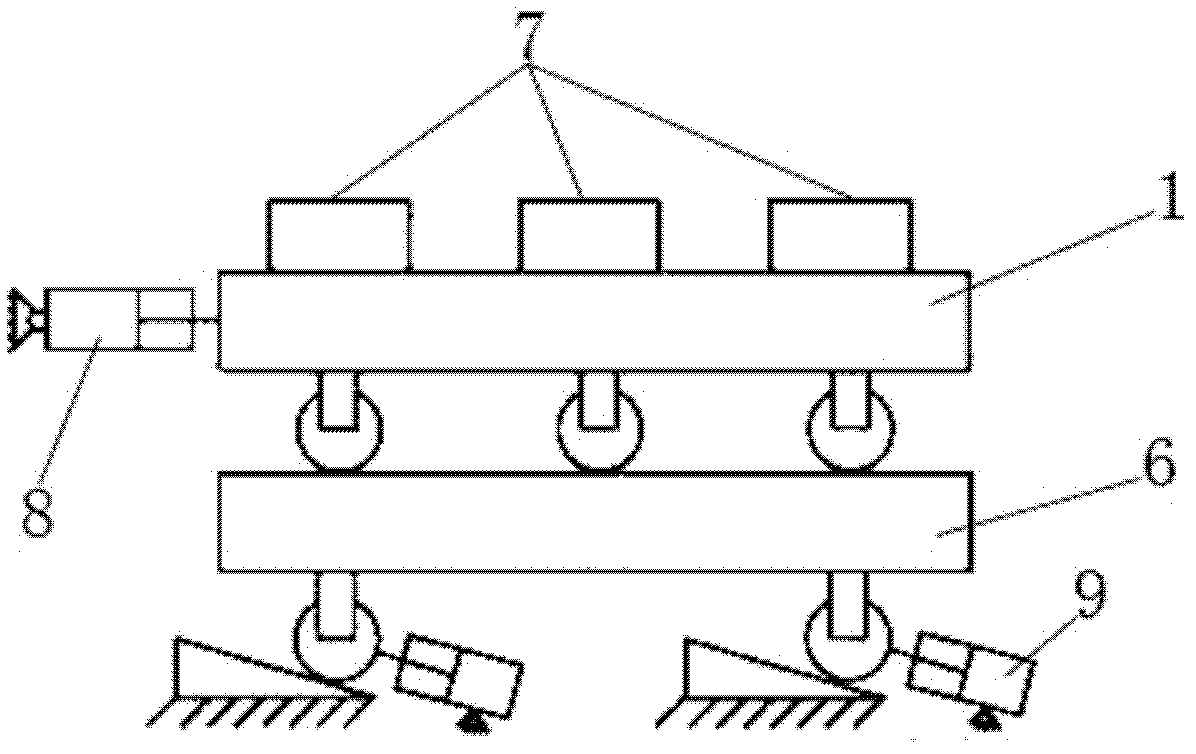

[0062] (3) Laser detector. The transmitter of the detector uses a semiconductor laser as the light source. After modulation, it emits a beam of red laser. control signal. At this time, the power and signal indicators of the receiving end device are both green. When the slab is lifted up on the movable beam of the walking beam or moves forward, and the laser light source is covered, the detector at the receiving end has no light source to receive. Arrived, the output control signal is output at a high level, collected by the on-site ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com