LCD (Liquid Crystal Display) touch-controlled all-in-one machine and manufacturing method thereof

A manufacturing method and an all-in-one machine technology, applied in the direction of static indicators, optics, instruments, etc., can solve the problems of high power consumption, low reliability, and large volume, and achieve the goals of saving electric energy, avoiding Newton rings, and avoiding loss of brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

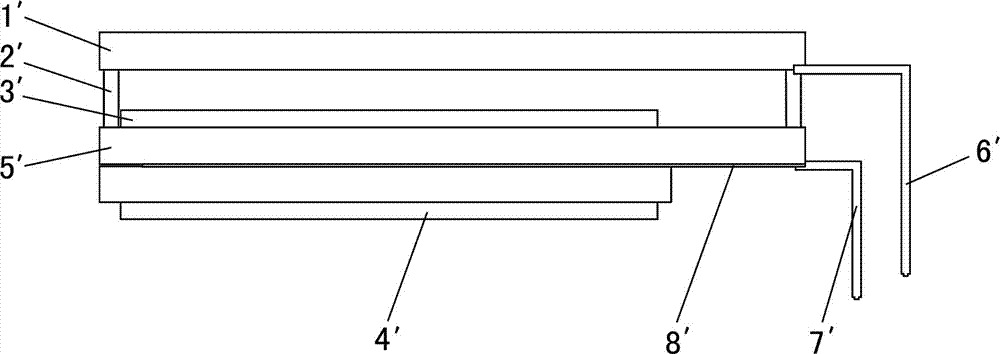

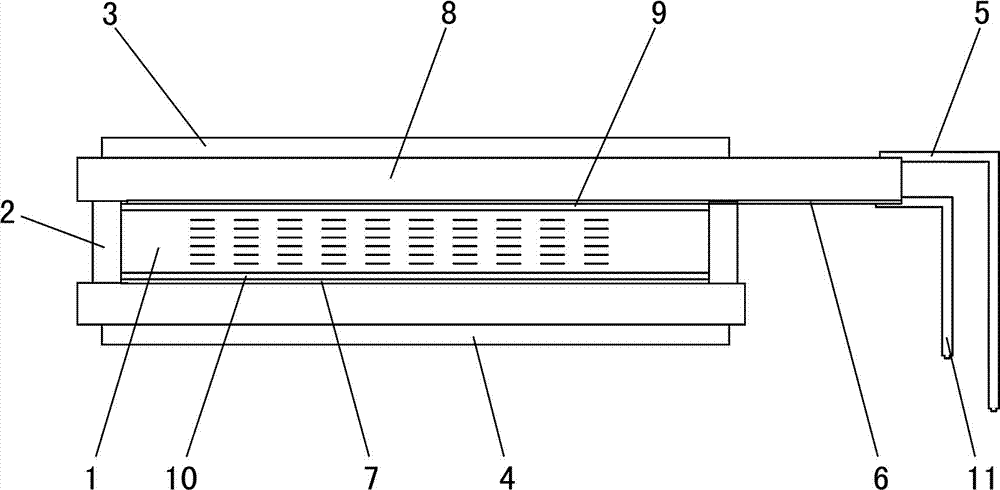

[0054] Such as image 3 As shown, the LCD display and touch all-in-one machine in this embodiment includes a liquid crystal box, an upper polarizer, and a lower polarizer. The upper surface of the liquid crystal box is provided with a touch screen sensing electrode, and the upper polarizer is arranged on the touch screen sensing electrode. On the surface, the first LCD display electrode and the second LCD display electrode are arranged in the liquid crystal cell, and the lower polarizer is arranged on the lower surface of the liquid crystal cell.

[0055] The liquid crystal cell includes a first glass substrate and a second glass substrate, the first glass substrate and the second glass substrate are stacked, and a frame formed by a frame glue is arranged between the first glass substrate and the second glass substrate, and inside the frame Filled with liquid crystals, the touch screen sensing electrodes are arranged on the upper surface of the first glass substrate, the first...

Embodiment 2

[0091] The difference between the LCD display and touch all-in-one machine in this embodiment and Embodiment 1 is that:

[0092] The liquid crystal cell is an HTN type liquid crystal cell.

[0093] The difference between the manufacturing method of the LCD display and touch all-in-one machine in this embodiment and Embodiment 1 is that:

[0094] The parameters of printing etching paste in sub-step 1) of step b are: mesh number: 325, 22.5 degrees; latex thickness: 25um; screen tension: 30 plus or minus 1N; scraper material: PU, 80 degrees; screen Pitch: 6mm; Printing pressure: 5kg; Printing speed: 60mm / sec.

[0095] The temperature range of the baking in sub-step 1) of the step b is 130 degrees Celsius, and the baking time is 25 minutes.

Embodiment 3

[0097] The difference between the LCD display and touch all-in-one machine in this embodiment and Embodiment 1 is that:

[0098] The liquid crystal cell is an STN type liquid crystal cell.

[0099] The difference between the manufacturing method of the LCD display and touch all-in-one machine in this embodiment and Embodiment 1 is that:

[0100] The parameters of printing etching paste in sub-step 1) of step b are: mesh number: 285, 22.5 degrees; latex thickness: 20um; screen tension: 30 plus or minus 1N; scraper material: PU, 80 degrees; screen Pitch: 5mm; Printing pressure: 5kg; Printing speed: 50mm / sec.

[0101] The temperature range of the baking in sub-step 2) of the step b is 120 degrees centigrade, and the baking time is 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com