Method for measuring and compensating surface profile error of large rotary body part in real time

A technology of surface contour and real-time compensation, which is used in measuring/indicating equipment, metal processing machinery parts, milling machine equipment, etc. It can solve the error of surface contour error of rotating body parts, which is not suitable for measurement, cannot measure the spindle runout, and cannot measure the error of large rotating body parts. compensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

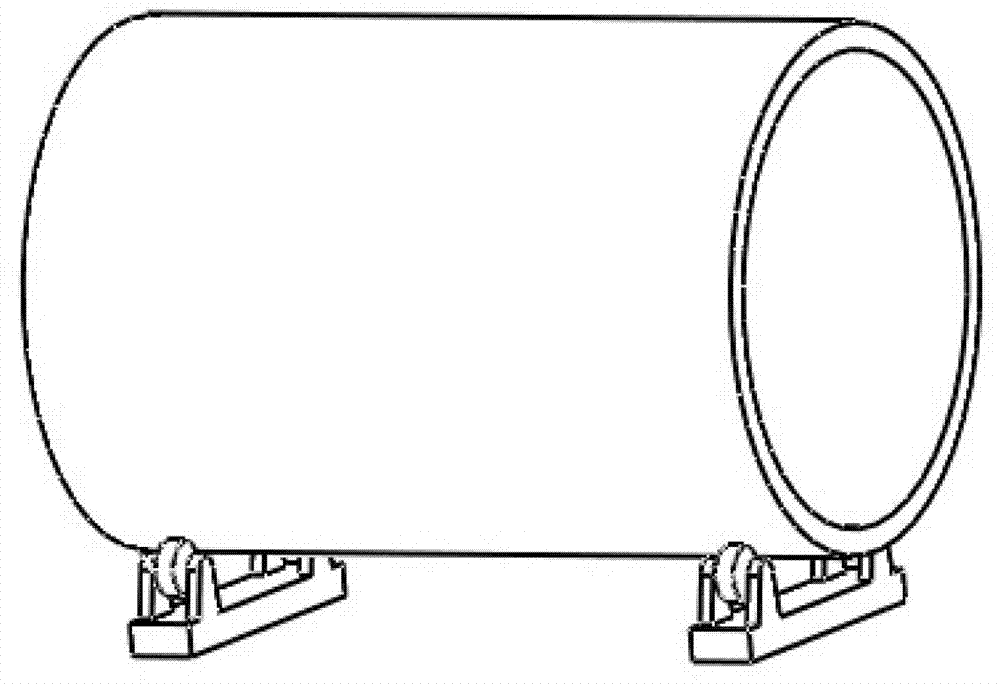

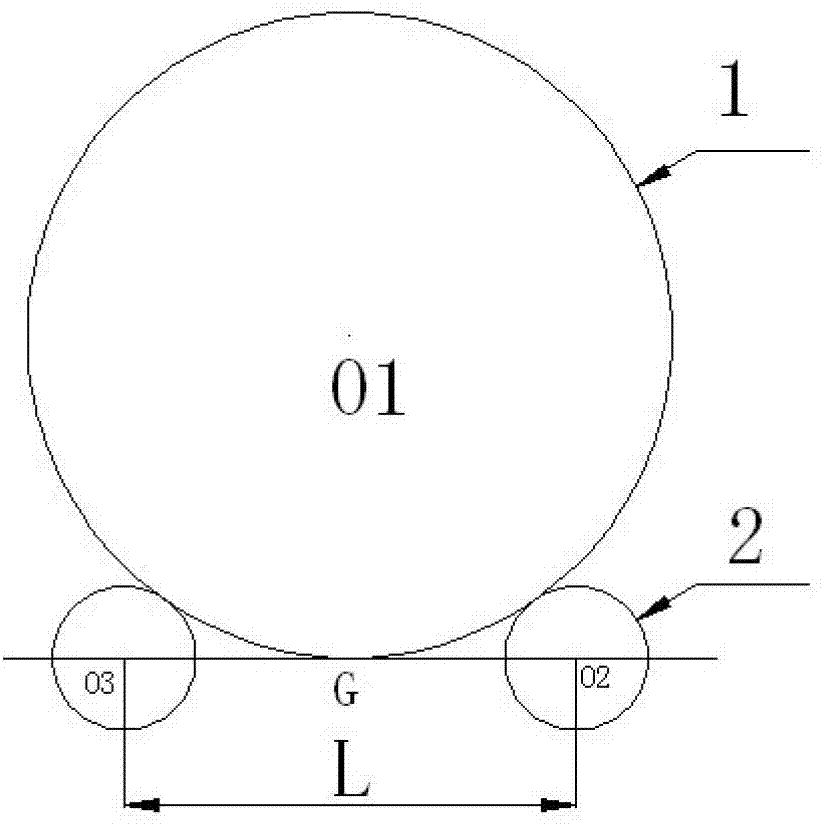

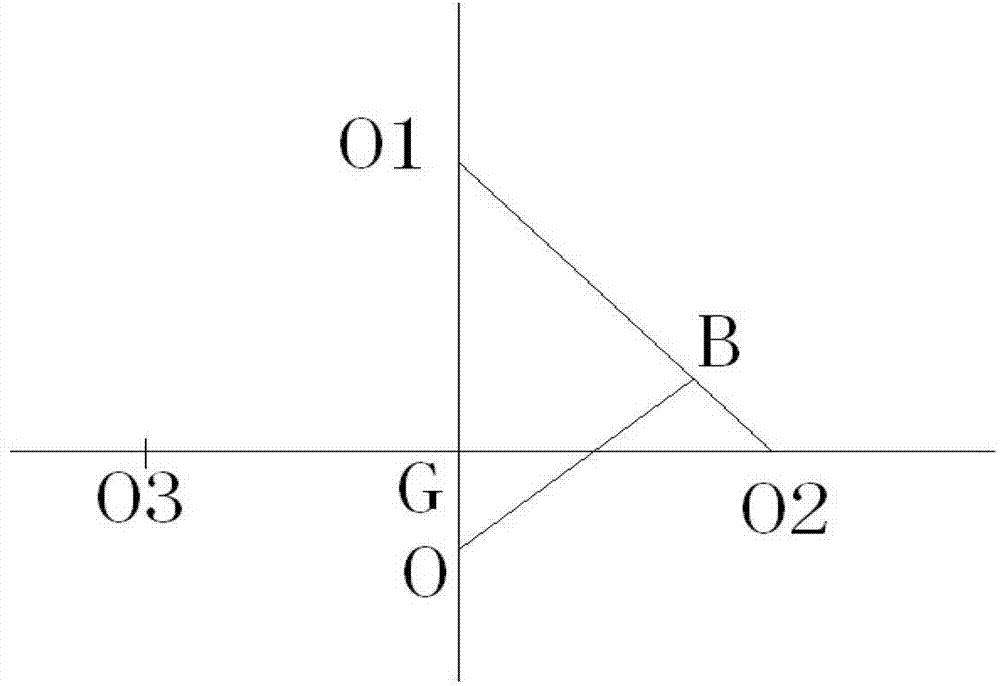

[0065] The method for measuring surface contour error and real-time error compensation of large-scale rotary body precision machining in this embodiment first calculates the V-shaped included angle formed by the idler structure and determines the number of sampling points according to the radius and machining accuracy requirements of large-scale rotary body parts; Carry out online measurement of body parts and rollers and perform data processing to calculate the contour error of the rotating body parts; finally, calculate the error compensation of each sampling point from the real-time measurement value of the surface contour error value of the rotating body parts and the radius error at the support point of the supporting roller during processing value.

[0066] Specifically include the following steps:

[0067] Step one, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com