Function safety monitoring development and demonstration system for major hazard source equipment

A functional safety and hazard source technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inability to warn and alarm, inability to realize emergency linkage, poor reliability, etc., and achieve the effect of avoiding personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The functional safety monitoring development and demonstration system for major hazard equipment proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

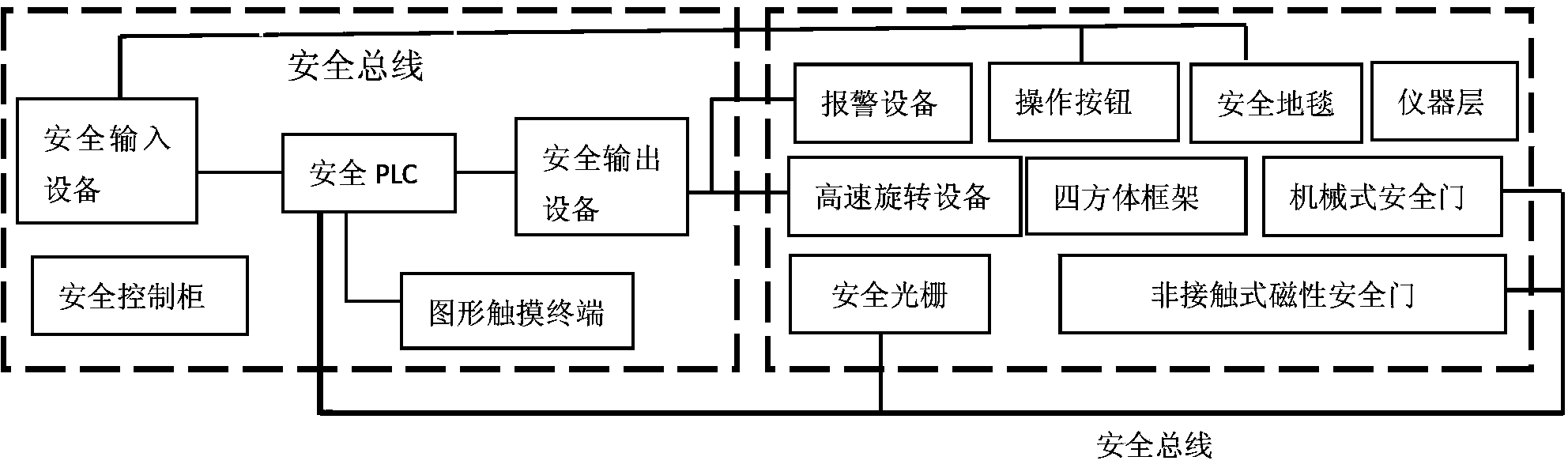

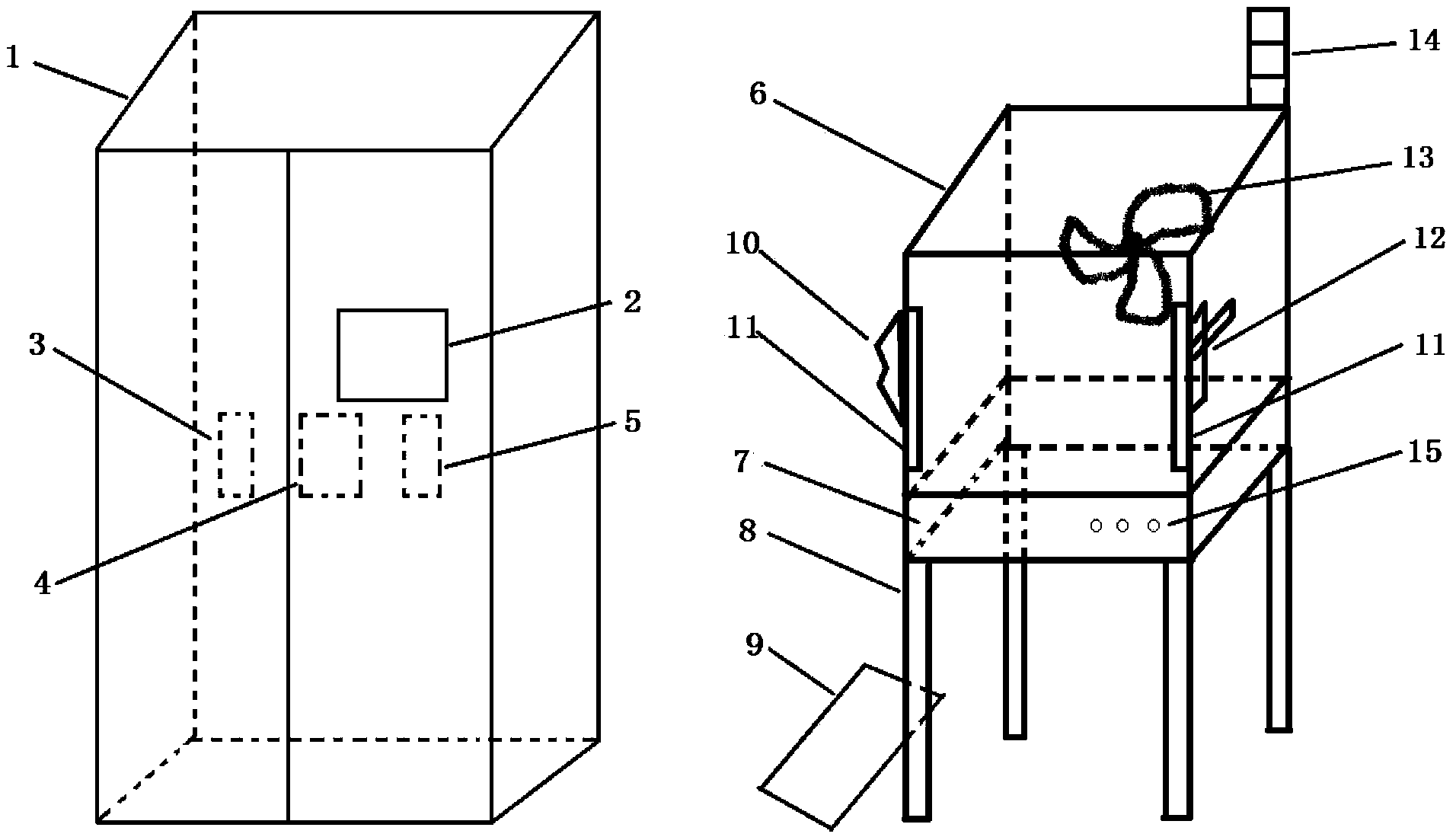

[0014] The overall structure of the functional safety monitoring development and demonstration system for major hazard source equipment of the present invention is as follows: figure 1 As shown, the system is mainly composed of a functional safety monitoring unit I and a safety protection and demonstration unit II; the functional safety monitoring unit is used for monitoring safety parameters and processing, analyzing, judging and logically calculating the collected data, and The calculation results are output to the safety protection and demonstration unit to realize the emergency stop of high-speed rotating equipment and the linkage alarm of alarm equipment. The safety protection and demonstration unit is used to realize the collection and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com