Assembly of electric motor starter components

A technology for starters and motors, applied in motor generators/starters, asynchronous induction motors, relays, etc., can solve the problems of increasing assembly and testing time, defects, etc., and achieve the effect of shortening assembly time and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

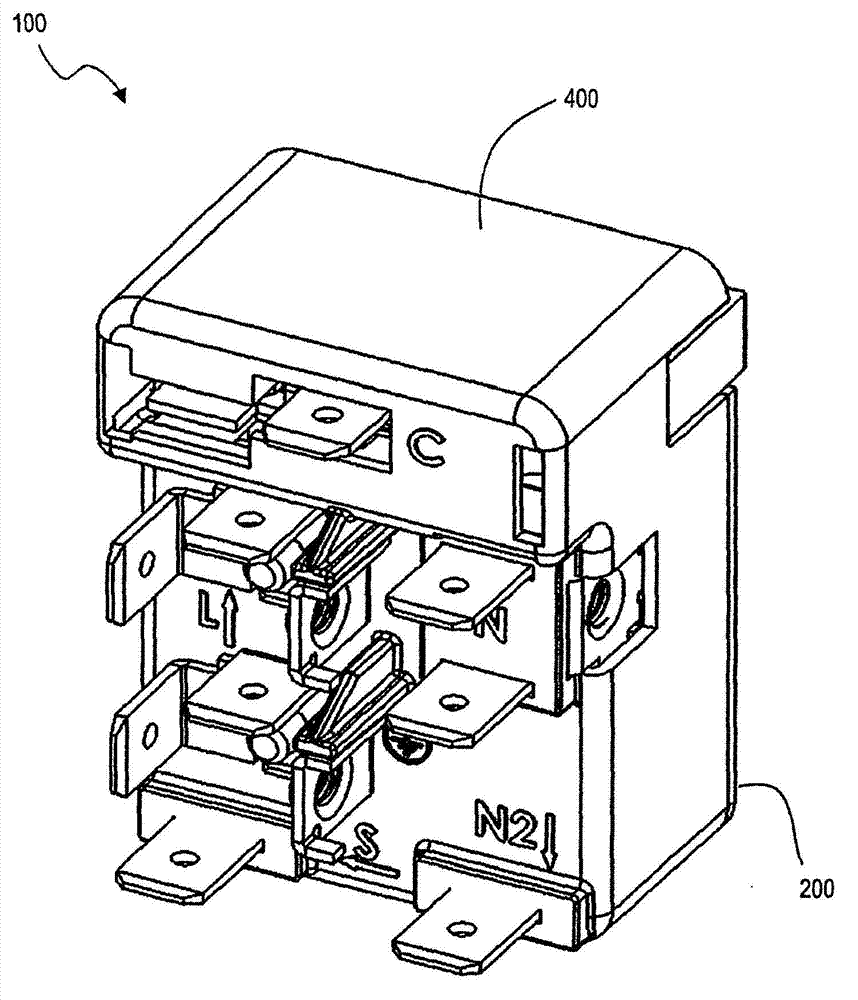

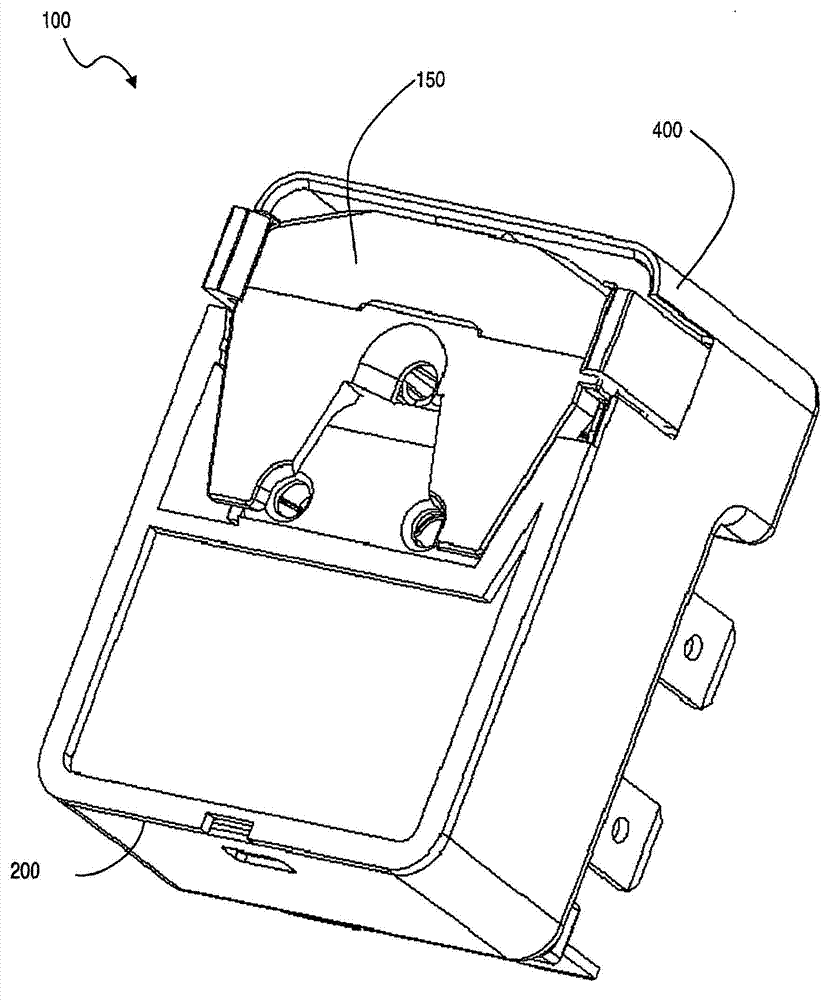

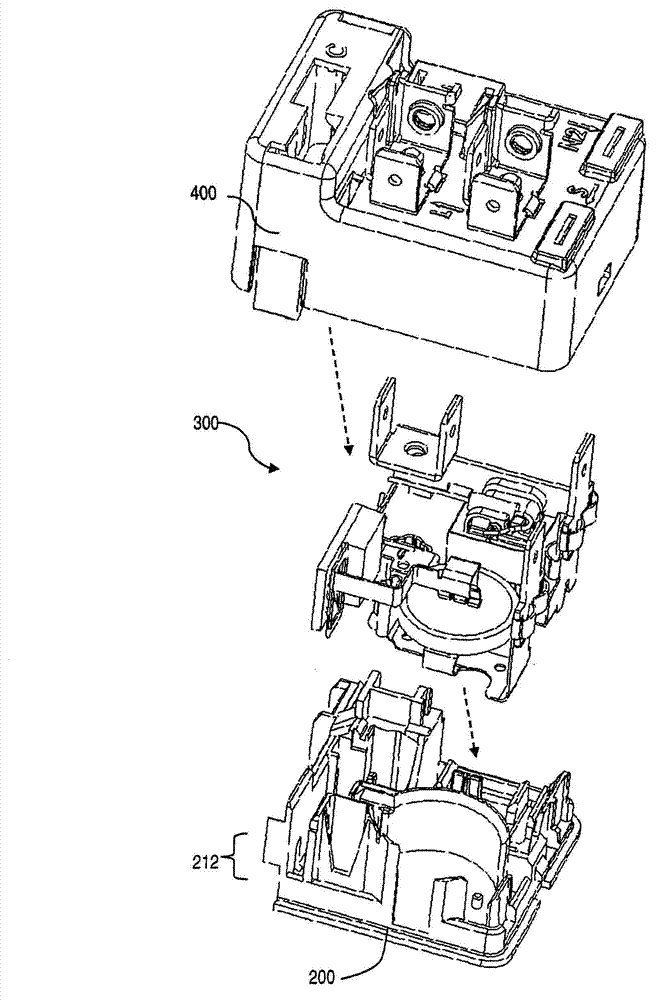

[0028]Technologies disclosed herein include systems and methods for assembling motor starter connection packs that enable increased automation and reduced assembly time. These systems and methods include device designs that enable top-down assembly of circuit assemblies, thereby enabling robotic placement, connection, and fixation of circuit assemblies. The device design also enables the secure connection of the motor starter circuit to the housing assembly without the need for circuit boards or filler material. The device design also enables rapid testing of the motor starter circuits and circuit components after the motor starter circuits and circuit components have been encapsulated by the housing. Additionally, the device design offers a universal base that accommodates a variety of cover and terminal configurations.

[0029] In general, an exemplary embodiment may include a motor starter with an optional overload protector that may be packaged as a unit. A motor starter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com