Automatic humidifier

An automatic and water filter technology, applied in baking, liquid spraying device, spraying device, etc., can solve the problems of noodles, broken strips, filament cracks, etc., so as to reduce the flower surface rate and the broken strip rate. , the effect of good water absorption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

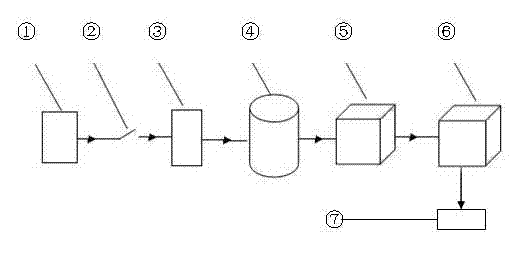

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

[0016] The automatic humidifier of the present invention comprises successively connected water wells ①, water filter ③, water storage tank ④, motor and CS temperature and humidity control system ⑤, pressure regulator ⑥ and nozzle ⑦, and the outlet of the water well is provided with a ball valve ②, connected with the motor The connected pressure regulator is located in the motor; the motor and water pump are used to pump water and pressurize it to spray out in mist form through the nozzle, and the pressure regulator is used to adjust the pressure and the particle size of the spray. Nozzle ⑦ is located in the airtight aging indoor space to be humidified. The connecting pipe communicates with the water well ①, the water filter ③, the water storage tank ④, the motor ⑤, the pressure regulator ⑥, and the nozzle ⑦.

[0017] The automatic humidifier of the invention is mainly composed of a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com