Dental implant capable of grafting bones

A technology for dental implants and dental implants, applied in dental implants, dentistry, dental prosthetics, etc., can solve the problem that the bonding strength of dental implants and gum bone is not high enough, the bonding time of dental implant and gum bone is long, and the dental implant The planting survival rate is not high enough to achieve the effect of compact structure, improved survival rate and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

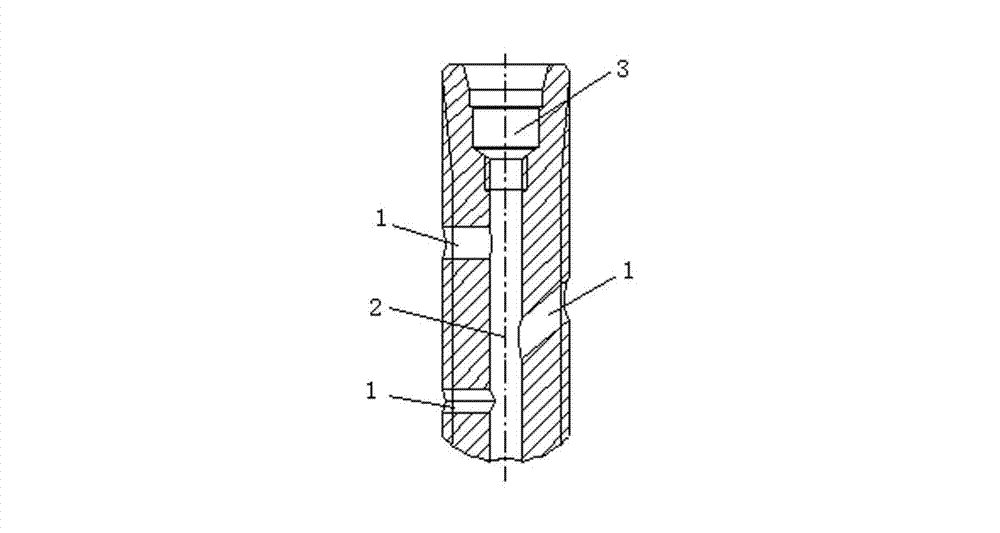

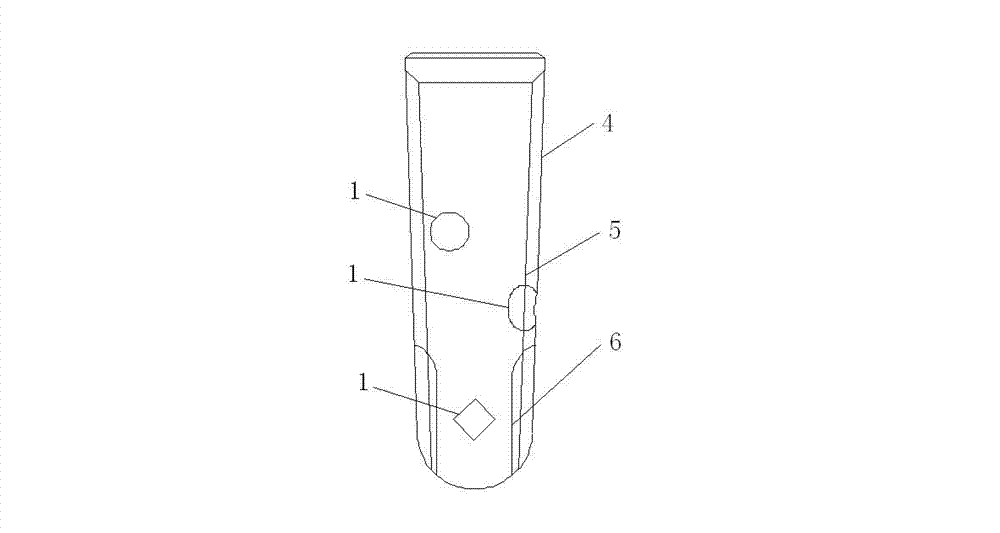

[0033] Refer to attached figure 1 , 2 The implantable dental implant has a dental implant body, the dental implant body has a through-hole structure 1, and the inner and outer walls of the dental implant body are connected through holes 2 of various regular and irregular shapes. There may be bone graft (bone filling) in the through hole 2 and the hole groove 1 of the dental implant body.

[0034] The shape of the through hole 2 and the hole groove 1 of the dental implant body can be various regular and irregular geometric shapes (shown in the accompanying drawings) image 3 Some regular shapes are listed). The number of holes and grooves of the dental implant body is not limited, as long as the bone grafting function is satisfied. The dental implant body can be made of pure titanium, titanium alloy, gold, bioactive ceramics, cobalt-chromium-molybdenum alloy, 316L stainless steel, PEEK and other materials.

[0035] The shape of the through hole and the hole groove of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com