Thin strip continuous casting method and device

A continuous casting and thin strip technology, which is applied in casting equipment, casting molten material containers, manufacturing tools, etc., to achieve the effects of improving the quality of casting strips, promoting the floating of inclusions, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

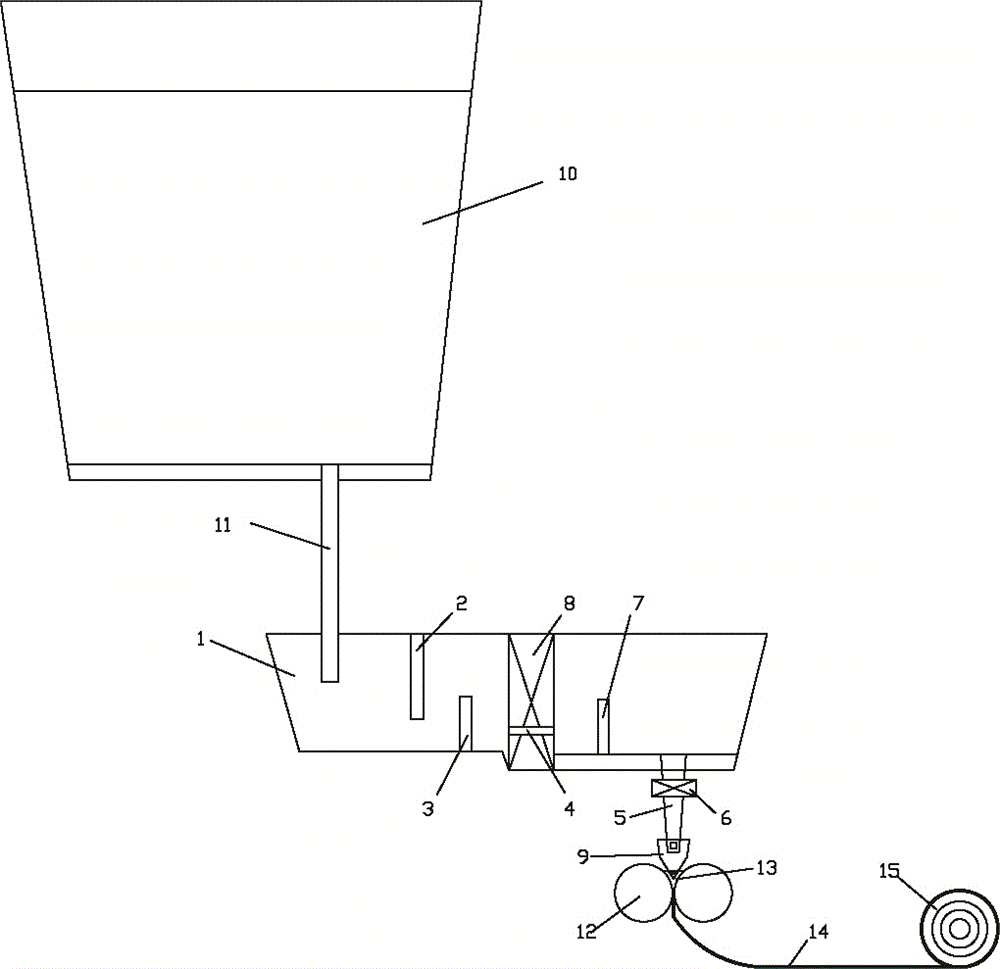

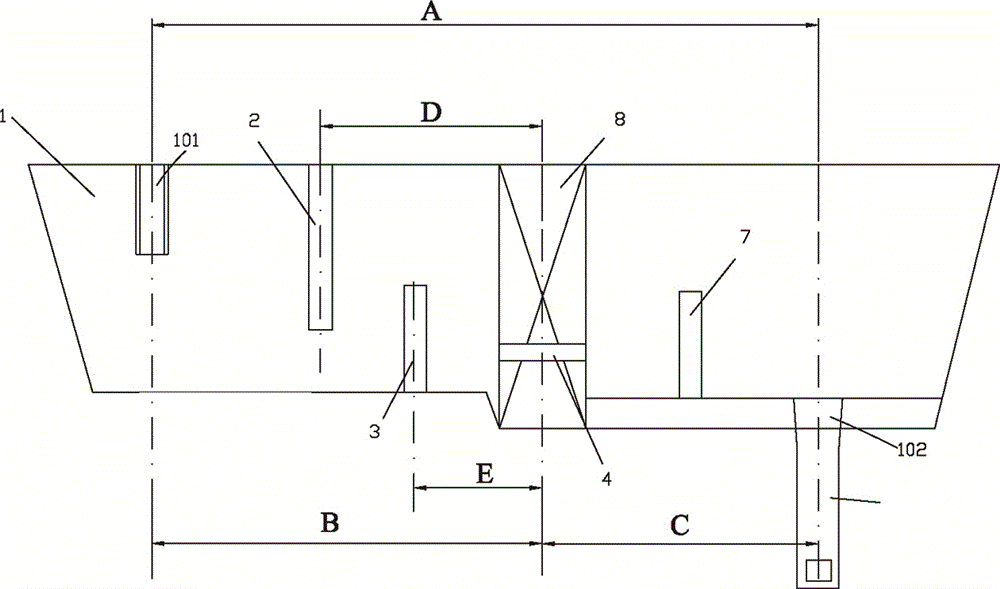

[0032] see Figure 1 ~ Figure 4 , a thin strip continuous casting method of the present invention, molten steel is injected from the ladle into the tundish 1 through the long nozzle, the tundish is a single-flow tundish, and the molten steel flows through the weir 2 on one side of the tundish , and then cross a first dam 3 and enter an induction-heated steel passing channel 4. The temperature of the molten steel after induction heating is 30-50°C higher than that of the tundish injection temperature, and the heated molten steel flows from the tundish 1 to the other. The outlet on one side flows out to the nozzle 5 for casting.

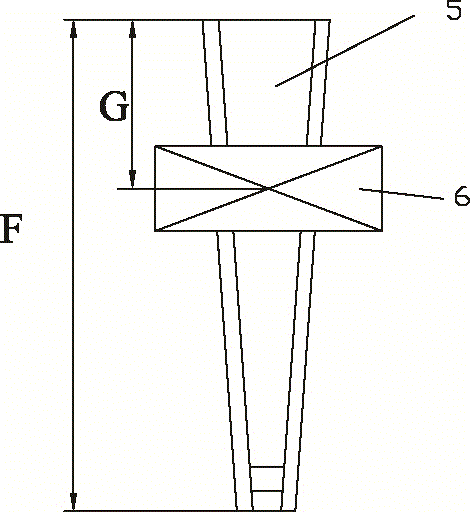

[0033] Further, a nozzle induction heater 6 is arranged outside the nozzle 5 .

[0034] The distance between the induction heater installed outside the nozzle and the upper port of the nozzle is 1 / 2 to 2 / 3 of the distance between the inlet and outlet of the tundish.

[0035] Moreover, the molten steel after induction heating crosses a second dam 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com