An enhanced wine production process

A production process and wine technology, which is applied in the field of enhanced wine production process to achieve the effect of saving time and cost, avoiding the process of reproduction and growth, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

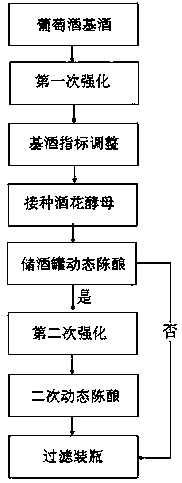

[0040] The invention provides a production process for biologically aged and fortified wine, the process flow comprising:

[0041] Base wine—the first fortification—base wine index adjustment—hop yeast inoculation—dynamic aging in wine storage tanks—filtering and bottling;

[0042] The specific operation steps are as follows:

[0043] S1: Base wine: Choose a wine with neutral aroma, dry type (residual sugar <4.0g / L, calculated as glucose), and low acidity (<6.0g / L, calculated as tartaric acid) as the base wine.

[0044] S2: The first reinforcement

[0045] The wine base wine is first fortified by using edible alcohol of 60-96% vol, so that the alcohol content reaches 15.0-15.5% vol.

[0046] S3: Base wine index adjustment

[0047] Adjust the indicators of the enhanced liquor to: pH: 3.1-3.5, 15-25°C, total SO 2 : 60-120ppm.

[0048] S4: Inoculation of hop yeast

[0049] Artificially inoculate the preferred film-producing hop yeast, the film-producing hop yeast is mainly ...

Embodiment 2

[0056] The invention provides a production process for oxidative aging and fortified wine, and the specific steps include:

[0057] S1: Base wine: Choose a wine with neutral aroma, dry type (residual sugar <4.0g / L, calculated as glucose), and low acidity (<6.0g / L, calculated as tartaric acid) as the base wine.

[0058] S2: The first reinforcement

[0059] The wine base wine is first fortified by using 60-96% vol of grape distilled spirit to bring the alcohol level to 15.0-15.5% vol.

[0060] S3: Base wine index adjustment

[0061] Adjust the indicators of the enhanced liquor to: pH: 3.1-3.5, temperature 15-25°C, total SO 2 : 60-120ppm.

[0062] S4: Inoculation of hop yeast

[0063] Artificially inoculate the preferred film-producing hop yeast, which belongs to the genus Bainula, to ensure that a sufficient amount of film-producing hop yeast can rapidly and normally reproduce and metabolize in the wine liquid, and ensure the normal and stable aging of the wine.

[0064] S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com