Manufacturing method of superabsorbent resin

A technology of superabsorbent resin and manufacturing method, which is applied in the field of manufacturing superabsorbent resin, and can solve the problems of low pressure absorption, gel clogging, and inability to meet the application of hygienic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The step of preparing water-absorbent resin powder as an intermediate base material suitable for the method of the present invention is not particularly limited, and can be a conventional method in the field, for example, the method for preparing water-absorbent resin powder as an intermediate base material disclosed in Chinese patent CN105848776A (This Chinese patent is inserted herein as a part of the present invention by way of citation).

[0026] In an example of the present invention, the step of described preparation intermediate base comprises:

[0027] - adding and mixing an acrylic monomer, an internal crosslinking agent, an aqueous solution of a chelating agent, an aqueous alkali solution, and water in a reaction vessel, thereby preparing a solution (A);

[0028] - Access N 2 Then add a polymerization initiator to carry out polymerization to obtain a water-containing gel-like cross-linked polymer;

[0029] - Disintegrating the obtained hydrogel-like cross-li...

Embodiment

[0071] Test Methods

[0072] "ENANA" is the abbreviation of European Nonwoven Industry Association. "ERT" is the abbreviation of the European Standard for the determination of superabsorbent resin. In the present invention, unless otherwise specified, the physical properties of the superabsorbent resin are measured in accordance with the original ERT (2002 revised edition / commonly known literature).

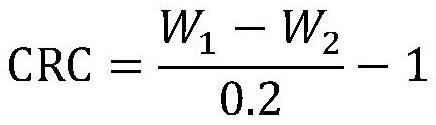

[0073] (1) Centrifugal water retention capacity (CRC)

[0074] The centrifugal water retention capacity (CRC) of the superabsorbent resin is measured according to the EDANA method (ERT441.2-02).

[0075]Specifically, 0.2 g of superabsorbent resin is evenly placed in a tea bag (60mm×85mm) and heat-sealed, and then soaked in a large amount (usually about 500ml) of 0.90wt at 23 (±2)°C. % NaCl aqueous solution. After 30 minutes, lift the bag, use a centrifuge (manufactured by Kokusan Co., Ltd., Japan, model H-122), remove water for 3 minutes with a centrifugal force of 250G, an...

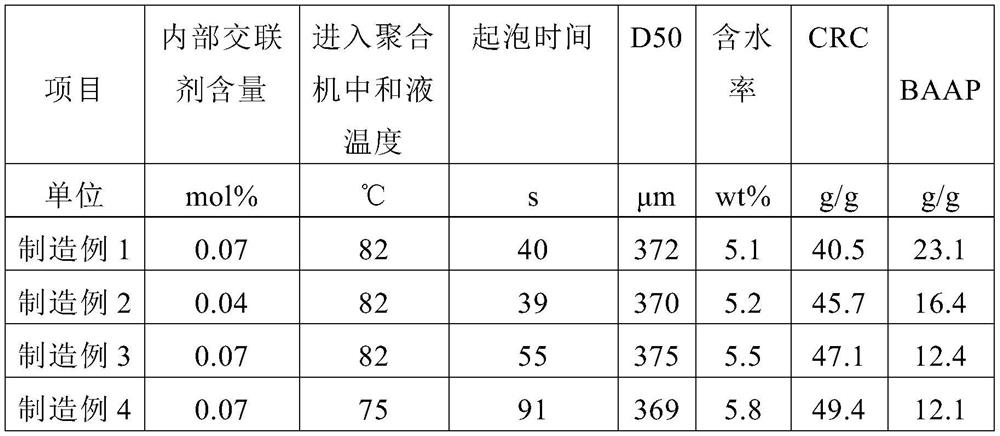

manufacture example 1

[0094] In a stainless steel container with a volume of 20 L, 5 kg of acrylic acid, 4345 g of deionized water and 4159 g of 50 wt % NaOH aqueous solution were put into the container, and the feeding speed of the NaOH solution was 832 g / min. During the dosing process of NaOH solution, precipitates can be observed, but gradually dissolve to form a transparent and uniform solution. When the dropwise addition was completed, the temperature of the neutralized liquid rose to 91° C. due to the heat of neutralization. Subsequently, adding 686 g of polyethylene glycol 400 diacrylate (Taiwan Changxing Materials Co., Ltd.) as a 4% internal cross-linking agent, a concentration of 5 wt% pentasodium diethyltriaminepentaacetic acid aqueous solution (BASF ) 14g, and under the effect of the circulating water bath of the vessel jacket, the temperature of the reaction solution was reduced to 88°C.

[0095] The reaction solution is pumped out through the stainless steel pipeline at a speed of 473...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com