Telomerization-free method and device for continuously preparing polysiloxane from cyclosiloxane

A technology of cyclosiloxane and polysiloxane, which is applied in the field of polymer compound preparation, can solve the problems of incomplete research on the polymerization mechanism and poor application of anions, etc., and achieve the goal of avoiding quality differences, stable product quality, and easy mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

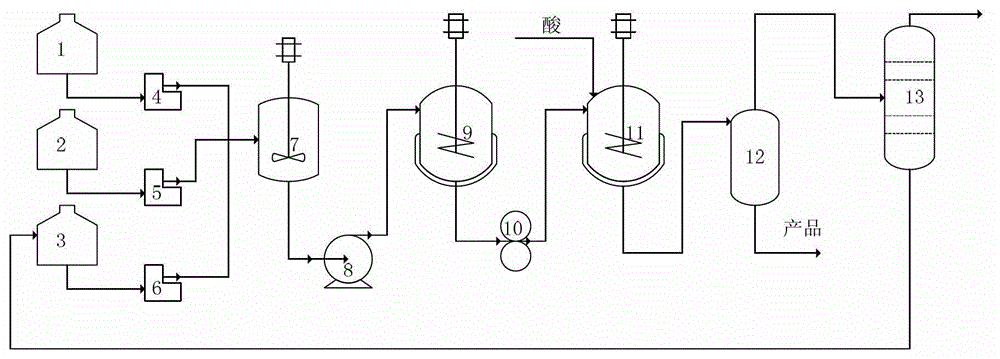

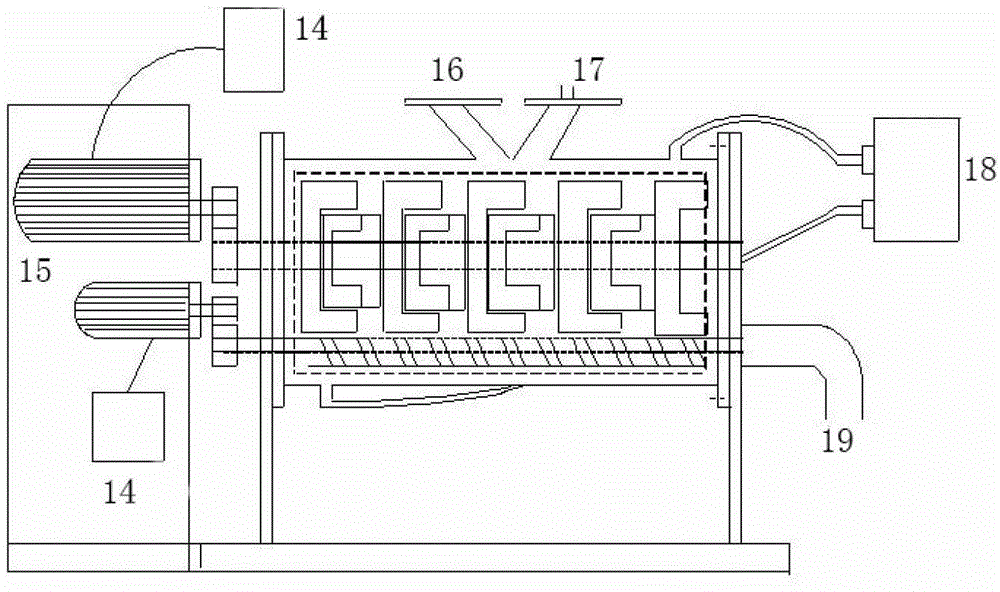

[0038] When carrying out the continuous polysiloxane polymerization process without telomerization of cyclosiloxane, the basic catalyst, molecular weight regulator and monomer are divided into five steps: mixing, polymerization reaction, catalyst deactivation, devolatilization and refining. The ratio of servings is as follows:

[0039] Monomer: 100 parts of octamethylcyclotetrasiloxane;

[0040] Basic catalyst: 0.06 parts of potassium hydroxide;

[0041] Molecular weight modifier: 0.1 part of water;

[0042] Catalyst deactivator: 0.06 parts of phosphoric acid.

[0043] All reactions are all completed in the device for continuously preparing polysiloxane without telomerization of cyclosiloxane of the present invention, and its working steps are as follows:

[0044] ① Mixing: Potassium hydroxide in the basic catalyst storage tank 1, water in the molecular weight modifier storage tank 2 and octamethylcyclotetrasiloxane in the monomer storage tank 3 are respectively measured by...

Embodiment 2

[0052] When carrying out the continuous polysiloxane polymerization process without telomerization of cyclosiloxane, the basic catalyst, molecular weight regulator and monomer are divided into five steps: mixing, polymerization reaction, catalyst deactivation, devolatilization and refining. The ratio of servings is as follows:

[0053] Monomer: 100 parts of dimethylcyclosiloxane mixture;

[0054] Basic catalyst: 0.03 parts of tetramethylammonium hydroxide;

[0055] Molecular weight regulator: 0.11 parts of water;

[0056] Catalyst Killer: None.

[0057] All reactions are all completed in the device for continuously preparing polysiloxane without telomerization of cyclosiloxane of the present invention, and its working steps are as follows:

[0058] ① Mixing: Potassium hydroxide in the basic catalyst storage tank 1, water in the molecular weight modifier storage tank 2 and octamethylcyclotetrasiloxane in the monomer storage tank 3 are respectively measured by the metering pu...

Embodiment 3

[0066] When carrying out the continuous polysiloxane polymerization process without telomerization of cyclosiloxane, the basic catalyst, molecular weight regulator and monomer are divided into five steps: mixing, polymerization reaction, catalyst deactivation, devolatilization and refining. The ratio of servings is as follows:

[0067] Monomer: 100 parts of octamethylcyclotetrasiloxane;

[0068] Basic catalyst: 0.06 parts of potassium hydroxide;

[0069] Molecular weight regulator: 0.12 parts of water;

[0070] Catalyst deactivator: 0.06 parts of phosphoric acid.

[0071] All reactions are all completed in the device for continuously preparing polysiloxane without telomerization of cyclosiloxane of the present invention, and its working steps are as follows:

[0072] ① Mixing: Potassium hydroxide in the basic catalyst storage tank 1, water in the molecular weight modifier storage tank 2 and octamethylcyclotetrasiloxane in the monomer storage tank 3 are respectively measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com