Detachable guide edge and inner side rerailer

A technology of rerailing device and guide rib, which is applied in transportation and packaging, equipment fixed on the track, railway car body parts, etc. It can solve the problems of short rerailing distance, lack of wheel flange grooves, poor material hardness, etc., and achieve Accurate positioning, firm installation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

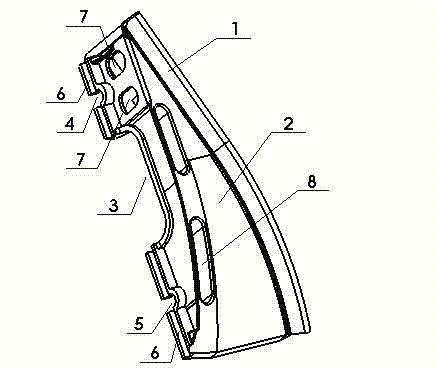

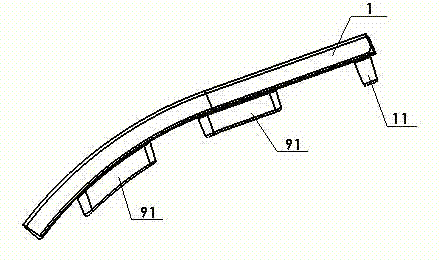

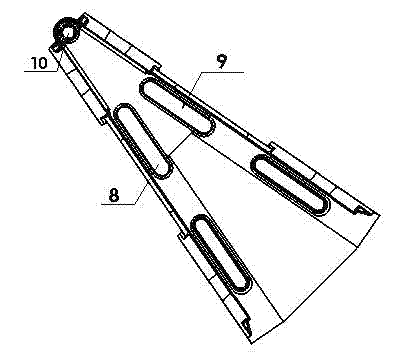

[0027] Embodiment one: if Figure 1 to Figure 5 with Figure 7 As shown, the detachable guide rib and the inner rerailer of the present invention are a detachable guide rib 1, which includes a guide rib body and a fixed protrusion, and the lower surface of the guide rib 1 is a plane and an arc surface or a parabolic surface The composite surface is formed, the plane is tangent to the arc surface or the parabolic surface, and one end of the guide rib 1 has a protrusion 11, and the other end is at least provided with a left guide rib-shaped slot 8 or The right guide rib-shaped slot 9 matches the bar-shaped protrusion 91. The cross-section of the detachable guiding edge 1 is a parabola or a triangle or a rectangle or a trapezoid.

[0028] An inner rerailer includes an inner rerailer body and a detachable guide edge 1. The upper sliding surface 2 of the rerailer is a composite surface composed of a plane and an arc surface, the plane and the arc surface are tangent, and the plan...

Embodiment 2

[0029] Embodiment 2: The structure of Embodiment 2 is basically the same as that of Embodiment 1, and will not be repeated. The inner rerailer is a little different in that the upper sliding surface 201 of the inner rerailer is an arc surface with a radius of 1200-2000 mm, and the lower surface of the detachable guide rib 101 is in line with the upper sliding surface 201 of the inner rerailer. Matching arc faces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com