Braking system for downward belt conveyor

A belt conveyor and braking system technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of automatic control of braking time, belt conveyor out of control, speeding accidents, etc., to avoid speeding accidents and Operator casualties, compact structure, and the effect of avoiding gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

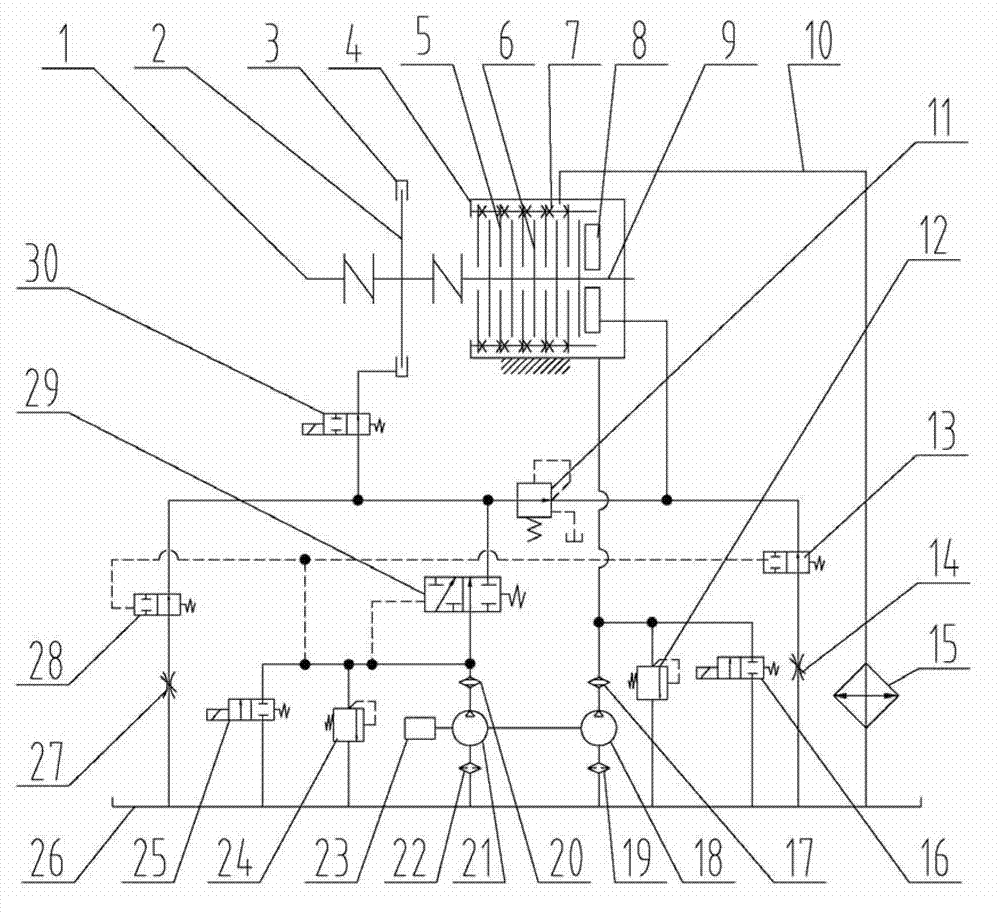

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] like figure 1 As shown, a brake system for down-conveyor belt conveyor, including belt conveyor drive roller shaft 1, hydraulic brake 4, propulsion cylinder 8, hydraulic brake shaft 9, throttle valve I14, lubricating oil pump 18. Pressure oil pump 21, belt conveyor reducer high-speed shaft 23, oil tank 26 and throttle valve II27; wherein the outer casing of the hydraulic brake 4 is fixed on the ground, and the outer friction plate 5 is connected with the outer casing of the hydraulic brake 4 ,, the inner friction plate 6 is connected with the shaft 9 of the hydraulic brake through a spline, and a disc spring group 7 is installed between each two outer friction plates, and a disc brake is also set in the system, wherein the disc brake disc 2 is connected with the belt The drive roller shaft 1 of the type conveyor is connected through a coupling, the brake head 3 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com