Polysilicon reduction apparatus

A polysilicon and reduction furnace technology, applied in the direction of silicon, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of huge energy consumption, high cost of polysilicon reduction furnace, low output, etc., to reduce investment and save energy Consumption and operating costs, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

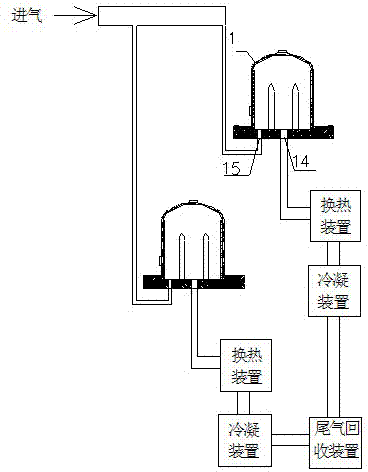

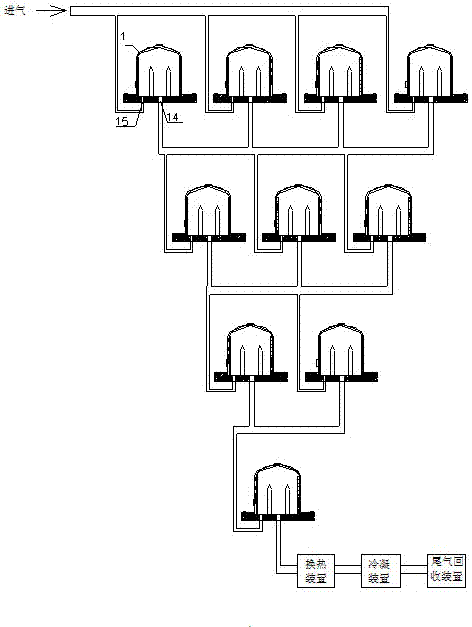

[0018] Example 1, such as figure 2 As shown, a polysilicon reduction device for producing polysilicon that the present invention relates to includes 10 polysilicon reduction furnaces 1, and the polysilicon reduction furnaces 1 are connected in parallel and then connected in series in four stages. The polysilicon of each stage of the polysilicon reduction device The number of reduction furnaces 1 is reduced step by step, that is, four polysilicon reduction furnaces 1 are connected in parallel in the first stage, three polysilicon reduction furnaces 1 are connected in parallel in the second stage, and two polysilicon reduction furnaces 1 are connected in parallel in the third stage. Furnace 1, the fourth stage is one polysilicon reduction furnace 1, and the gas outlets 14 of the four polysilicon reduction furnaces 1 in the first stage are combined with the three polysilicon reduction furnaces in the second stage respectively The gas inlet 15 of 1 is connected, and the gas outle...

Embodiment 2

[0020] Example 2, the rest is the same as in Example 1, the difference is that the polysilicon reduction device has 4 levels, the first level is connected in parallel with 6 polysilicon reduction furnaces 1, and the second level is connected with 4 polysilicon reduction furnaces 1 in parallel. Furnace 1, two polysilicon reduction furnaces 1 are connected in parallel in the third stage, and one polysilicon reduction furnace 1 is connected in the fourth stage.

[0021] In the above embodiments, the number of stages of the polysilicon reduction furnace 1 can be 2, 3 or 5, which is determined according to actual needs. The number of polysilicon reduction furnaces 1 at each stage can also be determined arbitrarily as required, as long as the number can be reduced step by step.

[0022] The beneficial effects of the present invention are: 1. Heat exchange device and condensing device are omitted, or the quantity or power of heat exchange device, condensing device and exhaust gas sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com