Condensing unit and clothes dryer with condensing unit

A condensing device and clothes dryer technology, applied in the field of clothes dryers, can solve the problems of cooling or heat loss, complex condensation heating structure, low drying efficiency, etc., achieve full recycling, improve drying efficiency, and fast cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

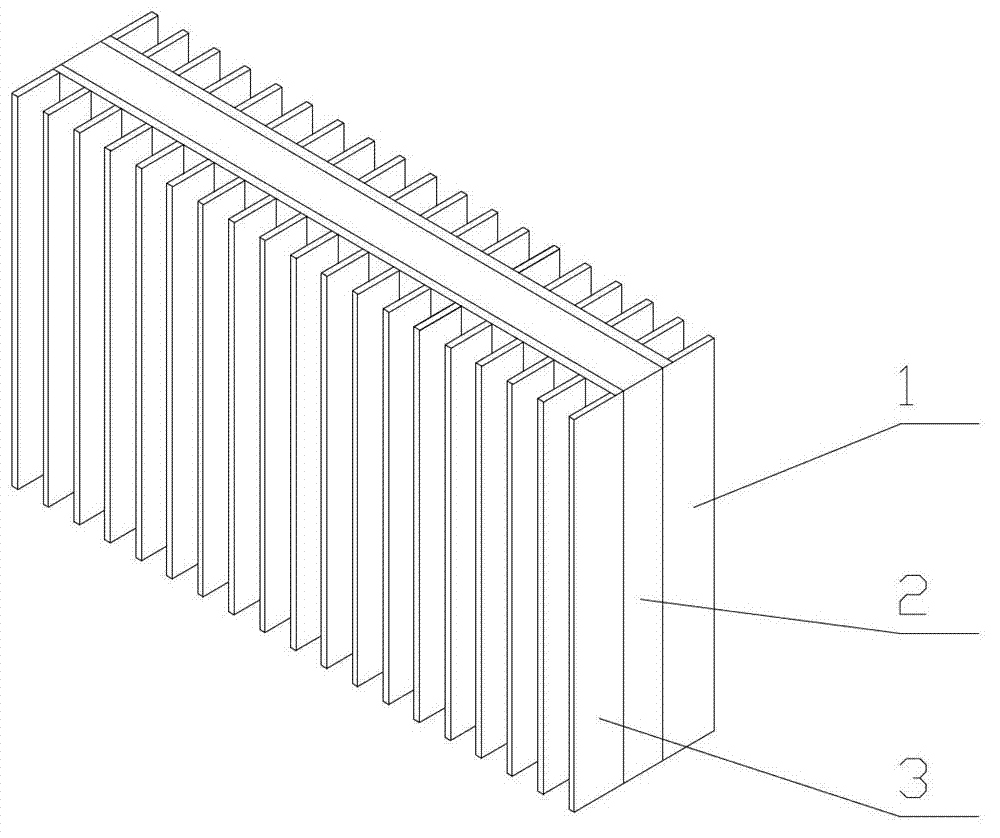

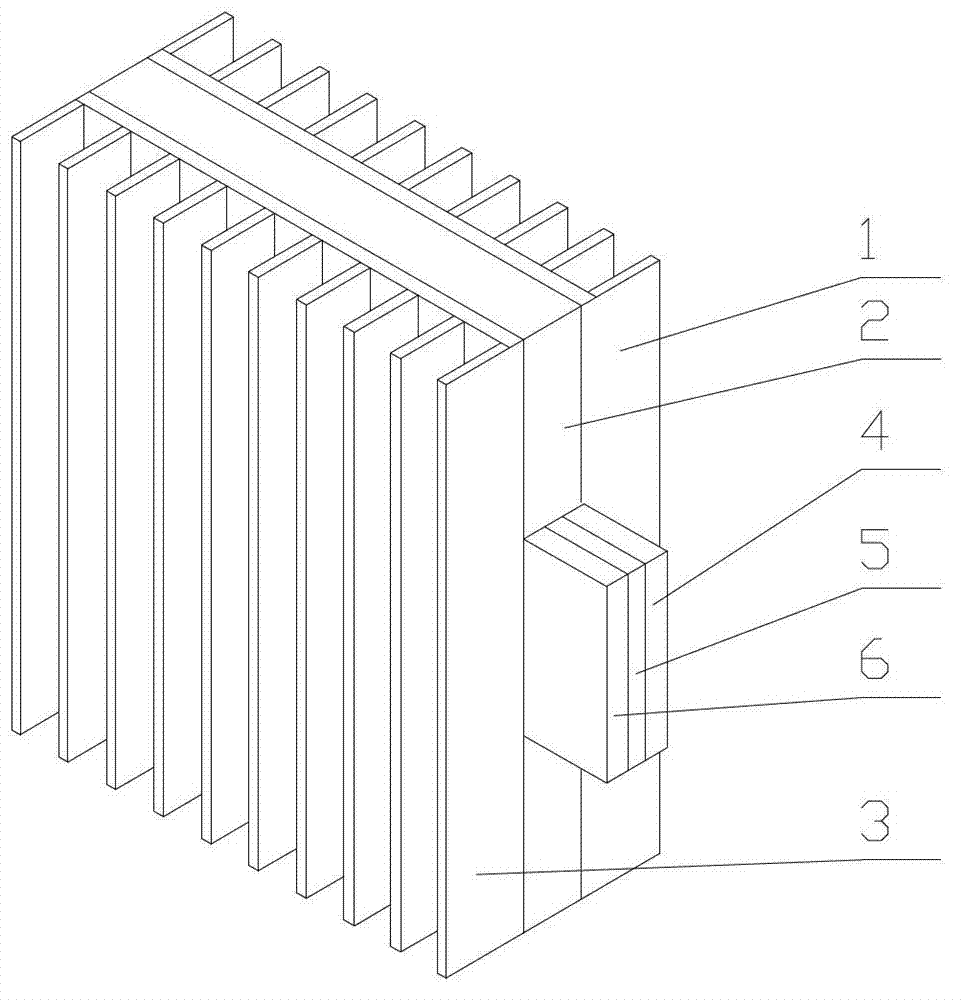

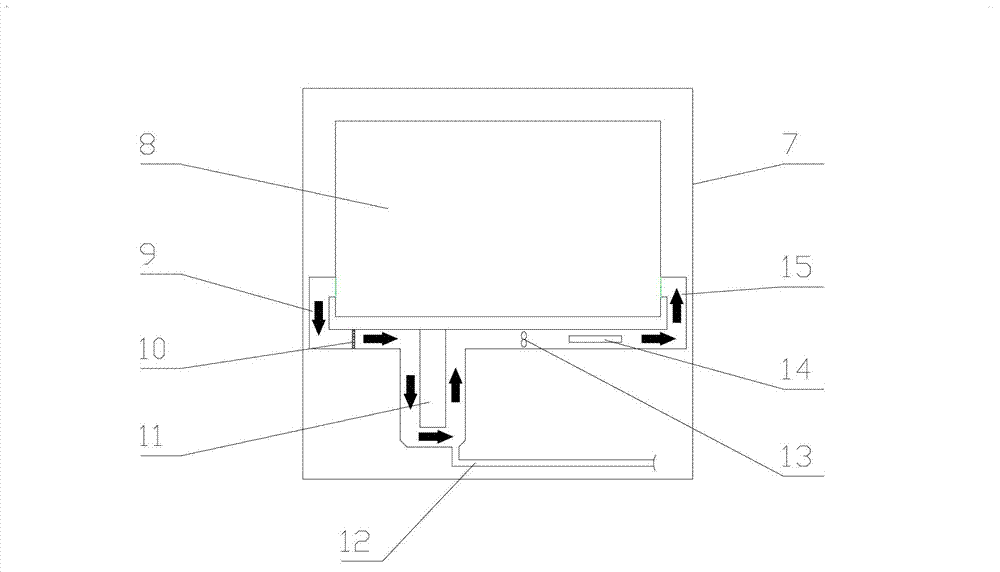

[0024] Such as figure 1 , figure 2 The condensing device shown includes a semiconductor cooling chip 5, the cold end of the semiconductor cooling chip 5 is connected to the cold end heat absorbing sheet 3 through the cold end heat conducting block 6, and the hot end is connected to the hot end heat sink through the hot end heat conducting block 4 1. Among them, the surface of the heat sink 3 at the cold end and the heat sink 1 at the hot end have a vertical grid structure, which can not only increase the area of heat absorption or heat dissipation, accelerate heat dissipation or heat absorption, but also facilitate the flow of condensed water. At the same time, heat insulating material 2 is filled between the heat sink 1 at the hot end and the heat absorber 3 at the cold end to isolate the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com