A kind of oil cylinder walking type thin coal seam shearer

A stepping, thin coal seam technology, applied in earthwork drilling, slitting machinery, propulsion, etc., can solve problems such as maintenance, inconvenient gear replacement, inability to adapt to extremely thin coal seams, and insufficient root strength, etc., to avoid broken teeth , wide practicability, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

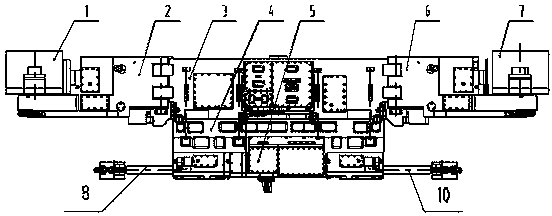

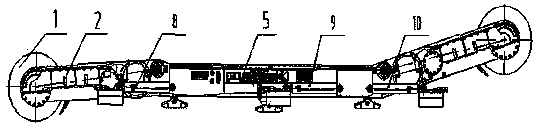

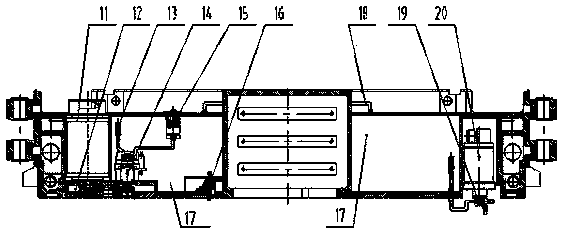

[0018] The oil cylinder walking type thin coal seam shearer of the present invention is mainly composed of a left drum 1, a left rocker arm 2, a pump station 3, a bridge crossing 4, a middle box 5, a right rocker arm 6, a right drum 7, I walking mechanism 8, and II walking mechanism Mechanism 9 and III walking mechanism 10 are composed of, and the I walking mechanism 8 includes a propulsion cylinder 23, a pin shaft 24, a retaining ring 25, a guide shoe 26, an I wedge block 27, a II wedge block 28, a locking cylinder 29, an angle steel 30 and spring 31; the propulsion cylinder 23 cylinder body is fixed on the middle case 5 through the stepped shaft 21 and the retaining ring 22, and the hydraulic rod of the propulsion cylinder 23 is connected with the guide shoe 26 through the pin 24 and the retaining ring 25; the locking cylinder 29 is fixed on the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com