Environment-friendly clean burner

A technology of clean combustion and burner, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of damage, unsatisfactory cleaning performance, low thermal efficiency, etc., to reduce temperature and oxygen concentration, and inhibit the production of harmful NO. , the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

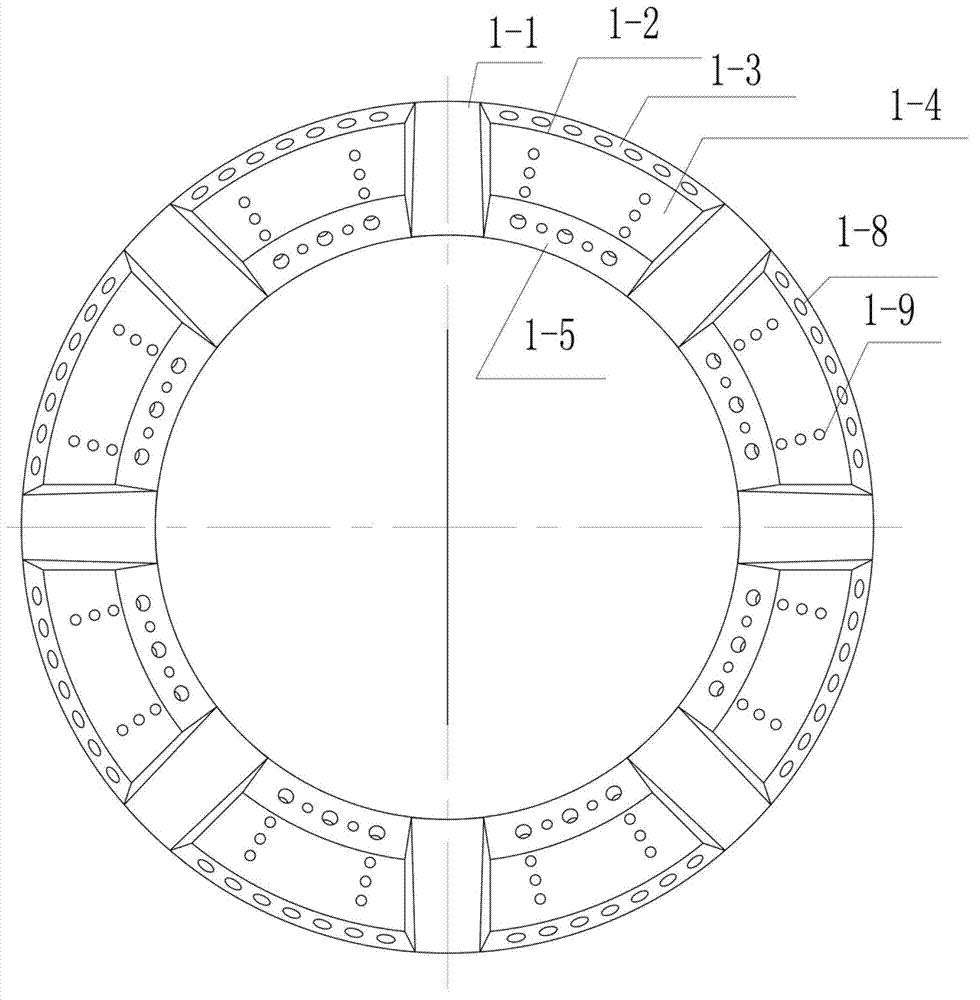

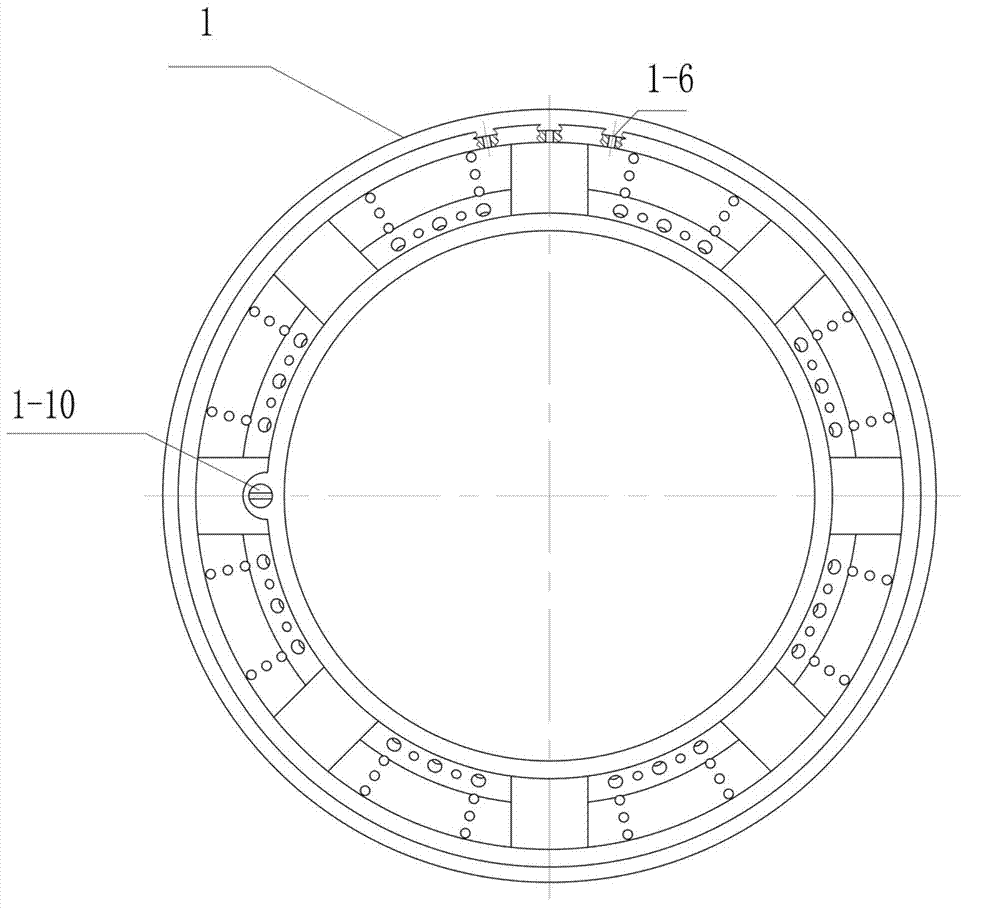

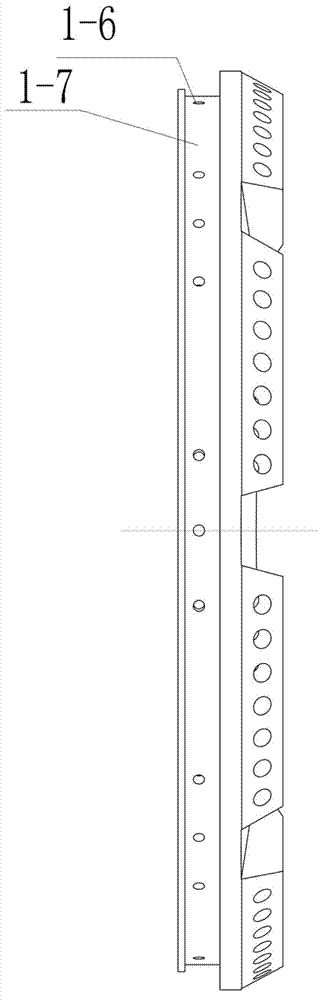

[0023] Such as Figure 1 to Figure 13 As shown, the environmentally friendly and clean burner of the present invention includes a temperature detection sensor, a copper core, a fire distributor, a hob, a burner bottom cup, a nozzle, a panel, panel fixing screws, and the like. The fire distributor is provided with 8 grooves and 8 bumps, several main fire holes are arranged on the outer slope of the bump; two rows of auxiliary fire holes are arranged on the front of the bump; several main and auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com