Industrial electric dust removing device purifying system

A purification system and industrial electricity technology, applied in the direction of external electrostatic separator, power supply technology, electrostatic separation, etc., can solve the problem that the purification effect cannot meet the requirements, and achieve the effect of good dust removal effect, low operating cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

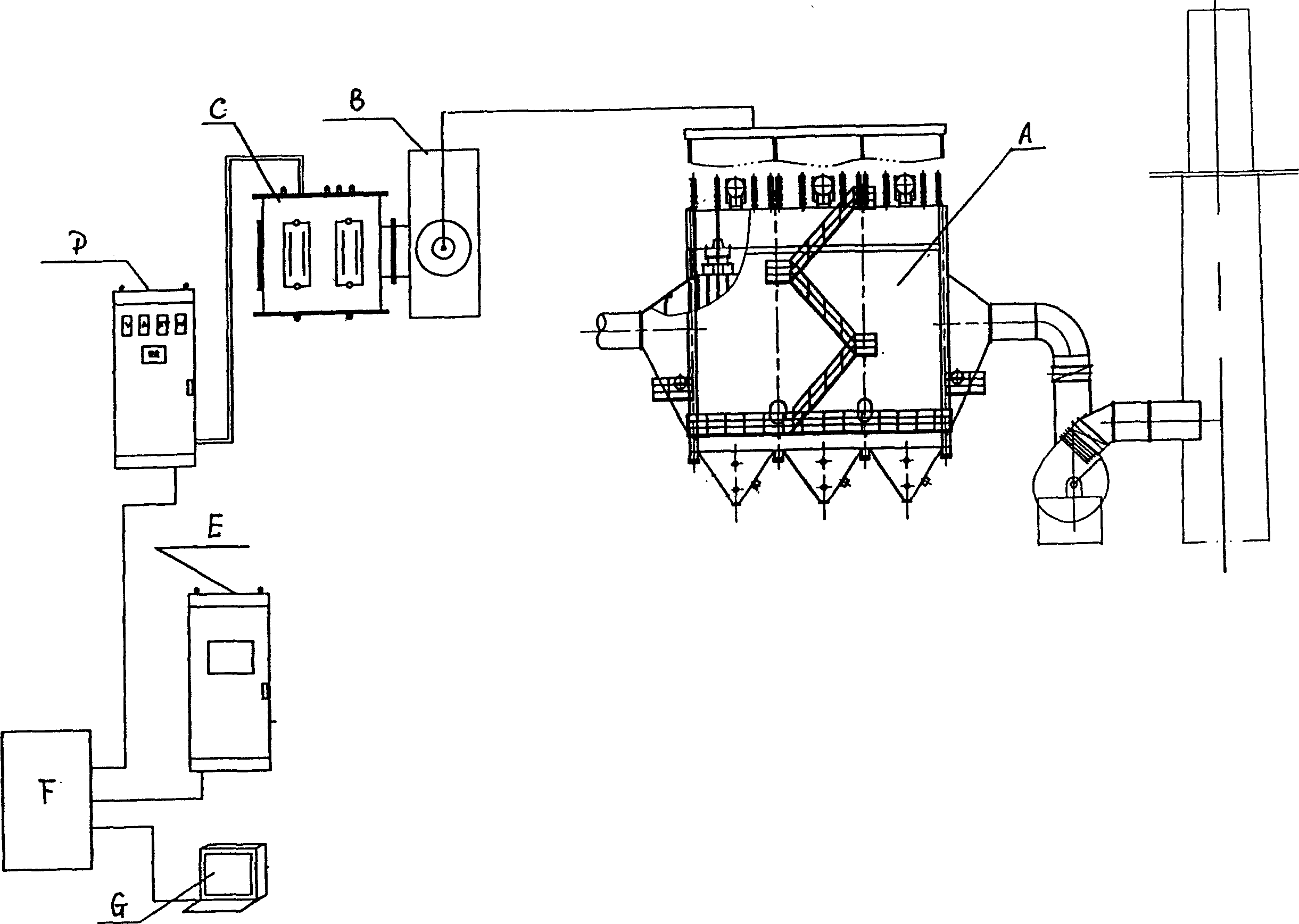

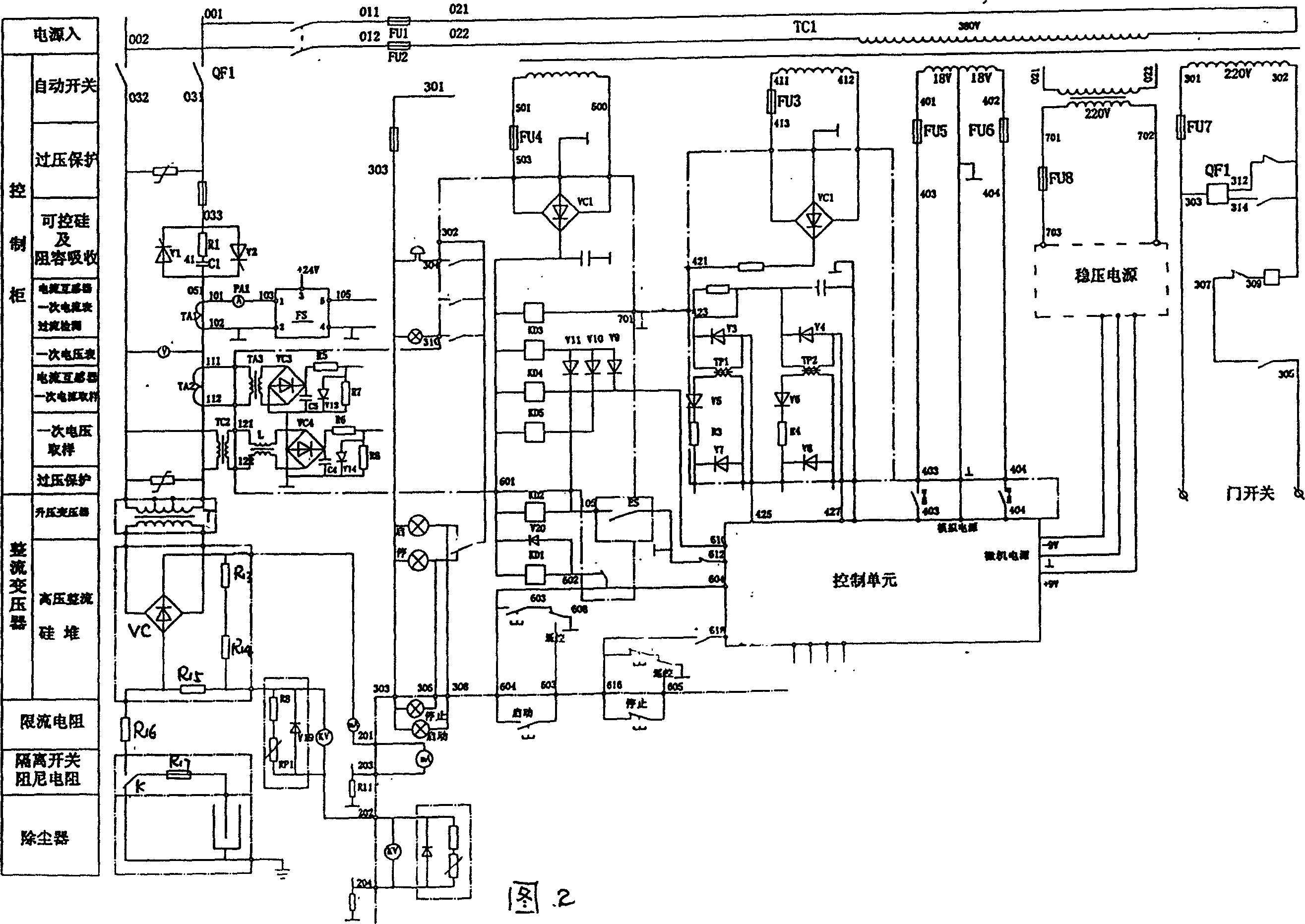

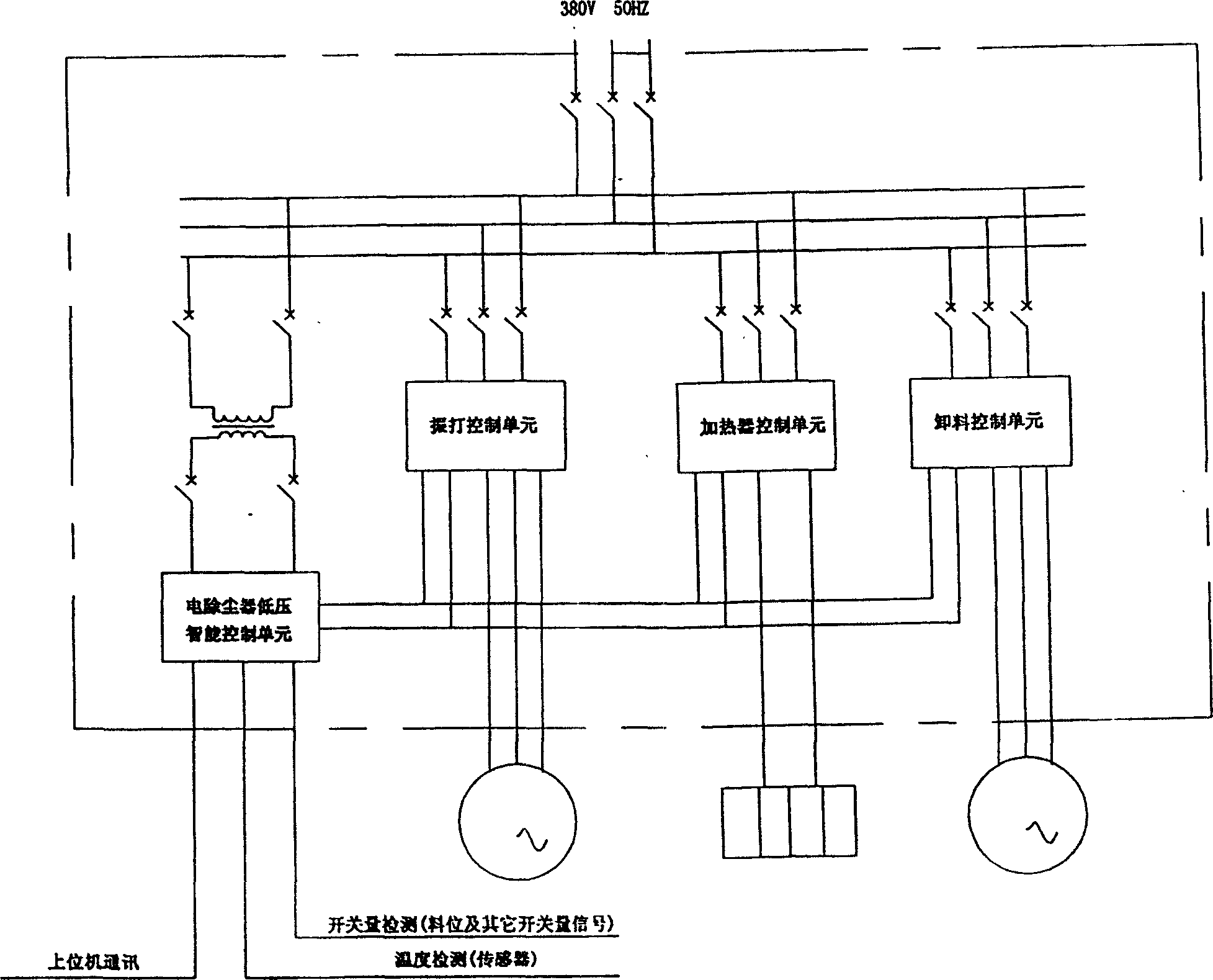

[0023] figure 1 ,figure 2, image 3 The specific description with reference to the accompanying drawings has been described in detail in the previous technical solutions.

[0024] See Figure 4 , the structural structure of the electromagnetic rapper on the top of the dust collector is: the rapping hammer 2 is set inside the insulating cylinder 1, the lower part of the rapping hammer 2 is a rapping rod 8, and the outer part of the rapping rod 8 is provided with a gasket 9; 1 There is a coil 3 on the outside, the outside of the coil 3 is the shell 4, and the outside of the shell is provided with a junction box 5, which is used to energize the coil, an insulating seal 6 is provided at the bottom of the coil 3, and the dust collector top plate 10 is at the bottom of the vibrator. There is a flange connection 7 outside the rapping rod and the rapping hammer.

[0025] Figure 5 It is the microcomputer control schematic diagram of electromagnetic rapping. The rectification devic...

Embodiment 2

[0029] See Image 6 , when dealing with asphalt fume, the dust collector 11 ( figure 1 Middle A) A spray cooler 12 is provided at the front end, a diffuser 13 is provided at the front of the spray cooler 12, a smoke separator 14 is provided at the front of the diffuser 13, and an asphalt filter is provided at the front of the smoke separator 14. Special electric butterfly valve 16.

[0030] As shown in Figure 7, the lower part of the spray cooler is provided with a drain pipe 17, a cleaning pipe 18, a water inlet pipe 19, and a spraying device 20, and an air distribution plate 21 is provided at the entrance of the spray cooler, and an airflow distribution plate 21 is provided at the entrance of the spray cooler. Air intake pipe 22 is arranged, and manhole 23 and temperature measuring connector 24 are also arranged on cooler.

[0031] As shown in Fig. 8 and Fig. 9, a frame 26 and an ash hopper 25 are provided at the bottom of the smoke separator, a side wall plate 30 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com