High-sensitivity FBG (Fiber Bragg Grating) acceleration sensor

An acceleration sensor, high-sensitivity technology, applied in the direction of acceleration measurement using inertial force, can solve the problems of grating axial strain grating pull-off, one sensitivity problem, chirp or multi-peak, etc., to improve sensitivity and avoid central wavelength The effect of chirping or broadening, of great practical significance and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

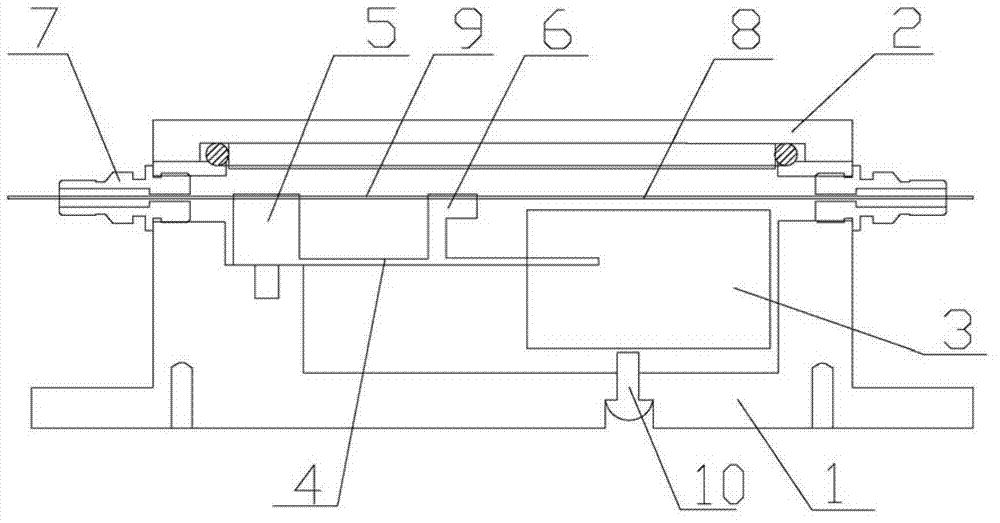

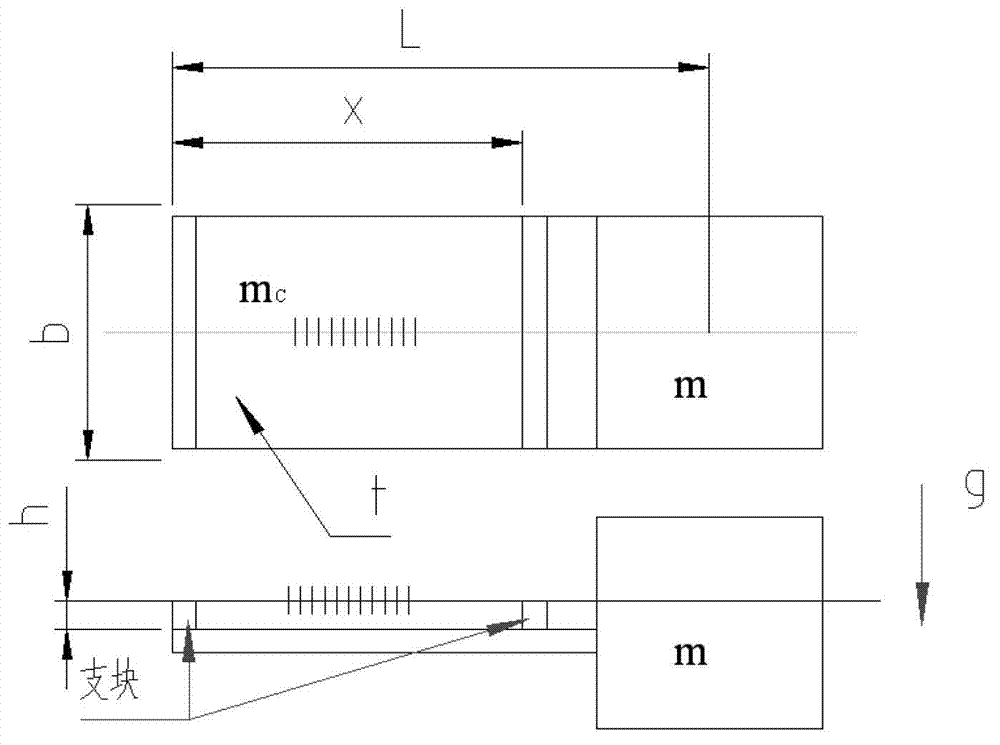

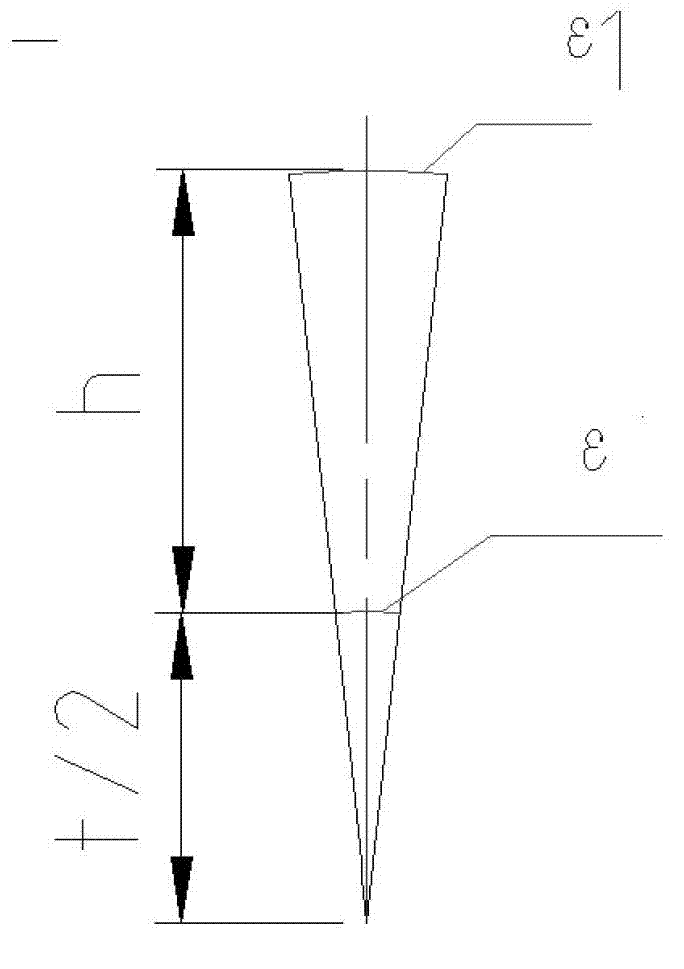

[0018] Example: such as figure 1 As shown, a high-sensitivity FBG acceleration sensor includes a base 1, an upper cover 2. The base 1 and the upper cover 2 are connected by screws, and the space formed by the base 1 and the upper cover 2 is provided with a cantilever beam 4, One end of the cantilever beam 4 is threadedly connected with the base 1, and the other end is threadedly connected with the mass 3. The mass 3 is in a suspended state. There are two support blocks on the cantilever beam 4, and the support block 5 is provided on the cantilever beam 4 and the base. At the connecting end of base 1, support block two 6 is set between support block one 5 and mass block 3. There are optical cable connectors 7 on both sides of base 1, and optical fiber 8 passes through two optical cable connectors 7 and is fixed to support block one 5 and On support block two 6, the grating grid region 9 is located between support block one 5 and support block two 6. Because the sensor is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com