Illumination module movement device

A mobile device and lighting module technology, applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of large space occupation, low connection rigidity, complex structure, etc., and achieve large tilt rigidity and high positioning accuracy , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

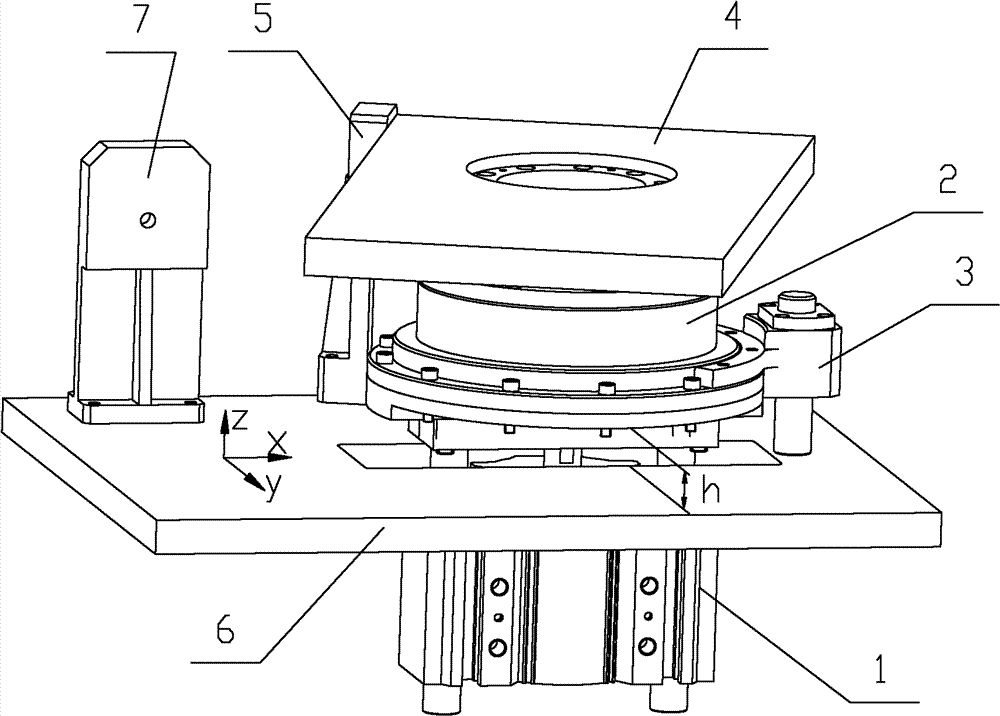

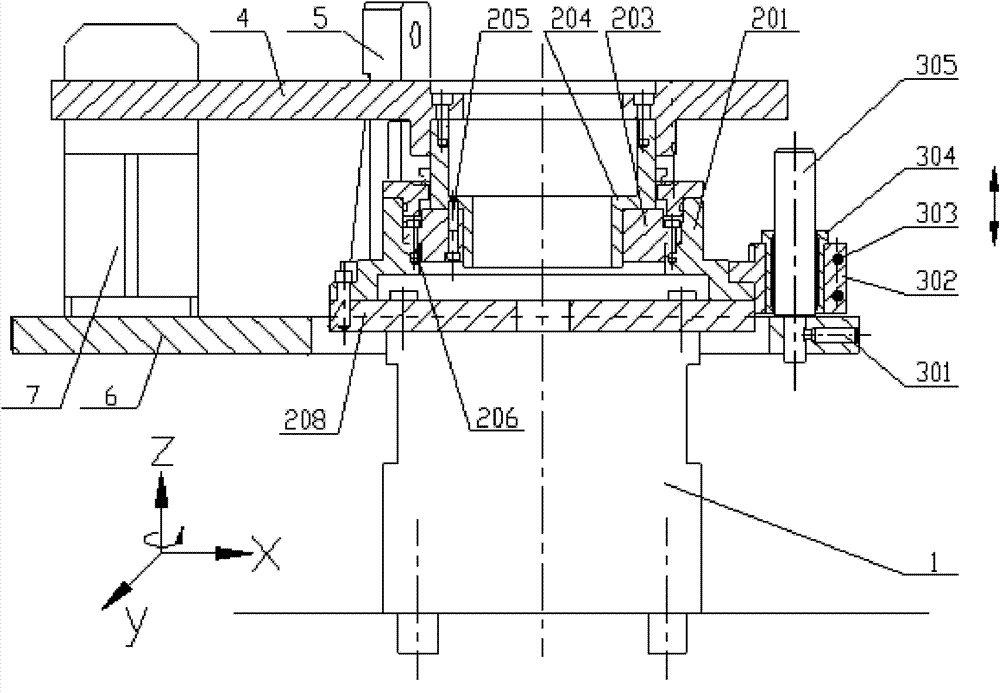

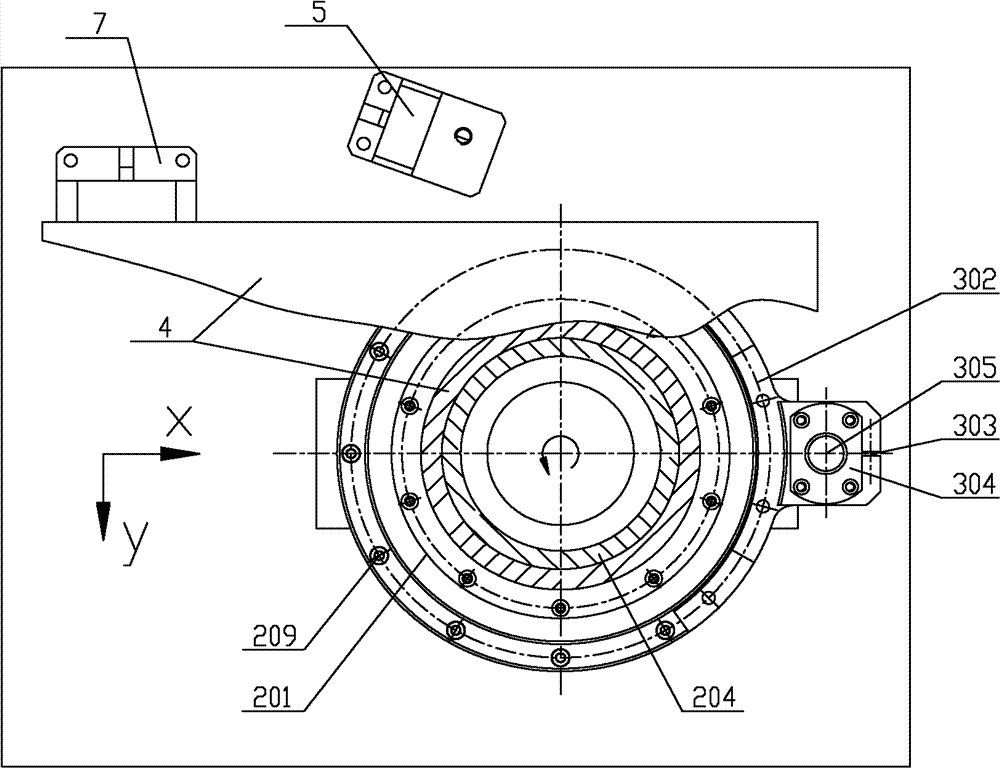

[0042] Please see figure 1 , figure 1 Shown is a schematic structural diagram of a mobile device according to a preferred embodiment of the present invention.

[0043] The moving device comprises a cylinder 1 , a rotating unit 2 , a guide module 3 , a bearing plate 4 , a first limiting block 7 , a second limiting block 5 and a base 6 .

[0044] The lighting module (not shown in the figure) is arranged on the carrying board 4 , and the carrying board 4 leans against the first limiting block 7 . The cylinder 1 drives the rotary unit 2 in the Z direction. After the rotating unit 2 is lifted by a fixed distance h, the bearing plate 4 can be rotated, and then the bearing plate 4 can be leaned against the second limit block 5 . The user can lock the bearing plate 4 on the second limit block 5 to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com