Double-sided circuit board structure

A double-sided circuit board and circuit board technology, which is applied in the direction of circuits, printed circuits connected with non-printed electrical components, electrical components, etc., can solve the problems of increased circuit board width, incompatible with the miniaturization of electronic devices, etc., and achieve Effects of reduced usage and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

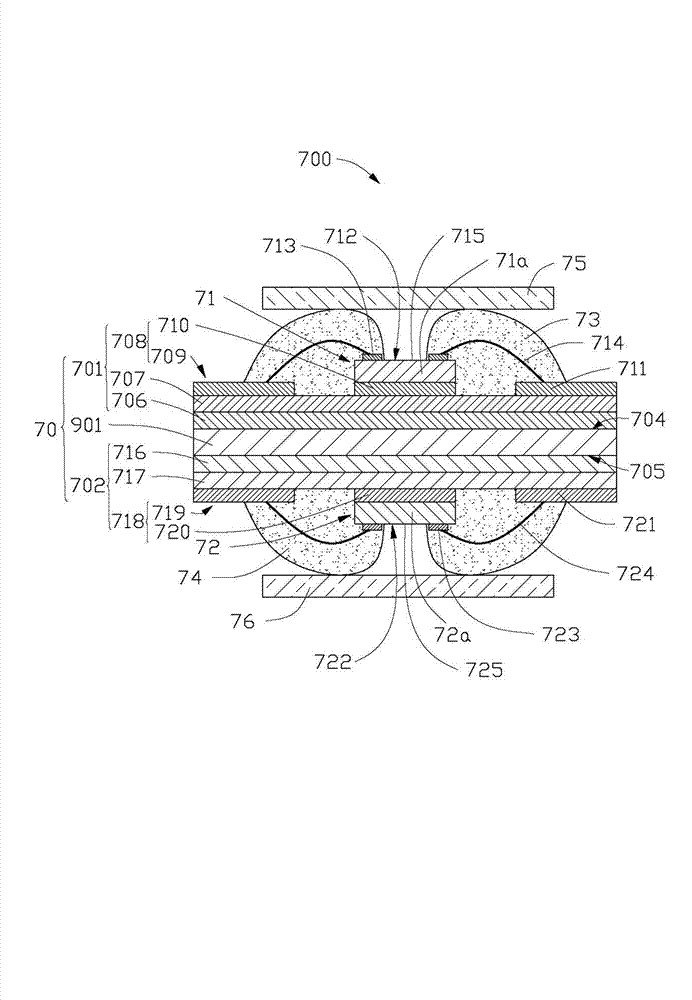

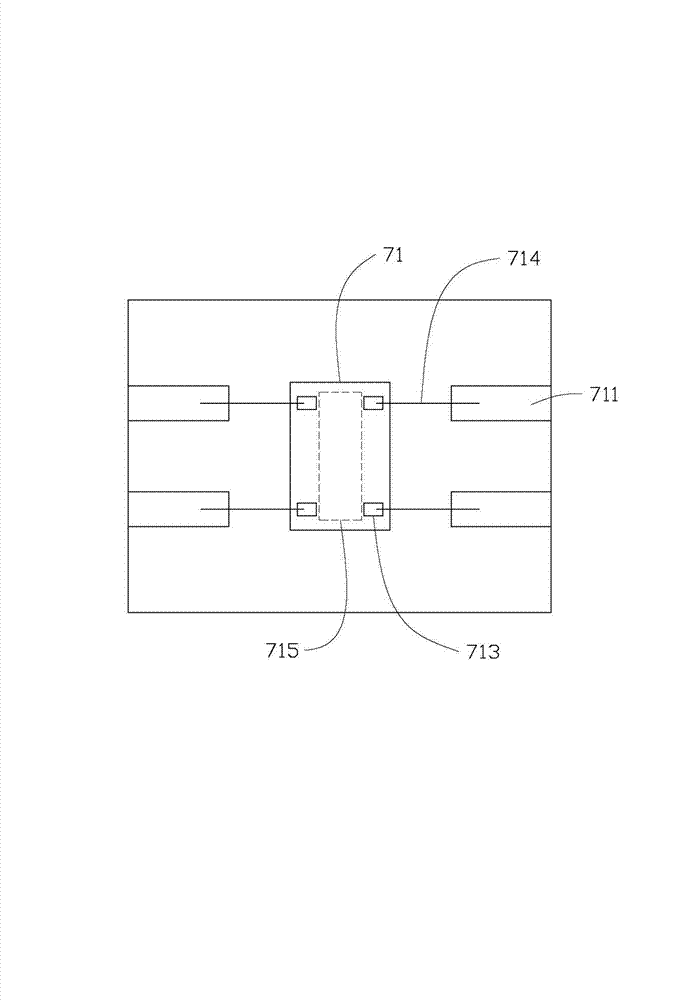

[0023] see Figure 1 to Figure 2 A double-sided circuit board structure 700 provided in the first embodiment of the present invention includes a circuit board 70, a first chipset 71, a second chipset 72, a first protective layer 73, a second protective layer 74, a first packaging glass 75 and the second packaging glass 76.

[0024] The circuit board 70 includes a spacer layer 901 , a first multilayer structure 701 and a second multilayer structure 702 . The spacer layer 901 includes a first surface 704 and a second surface 705 opposite to the first surface 704 . The first multilayer structure 701 is formed on the first side 704 , and the second multilayer structure 702 is formed on the second side 705 .

[0025] The first multilayer structure 701 includes a first circuit layer 706 formed on the first surface 704, a first intermediate layer 707 formed on the first circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com