Protective element for insertion into the front of an article of footwear, method of manufacture and article of footwear

A technology for protective elements and footwear, applied in the field of manufacturing said protective elements, capable of solving problems such as accelerated wear, non-integrated soles, discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

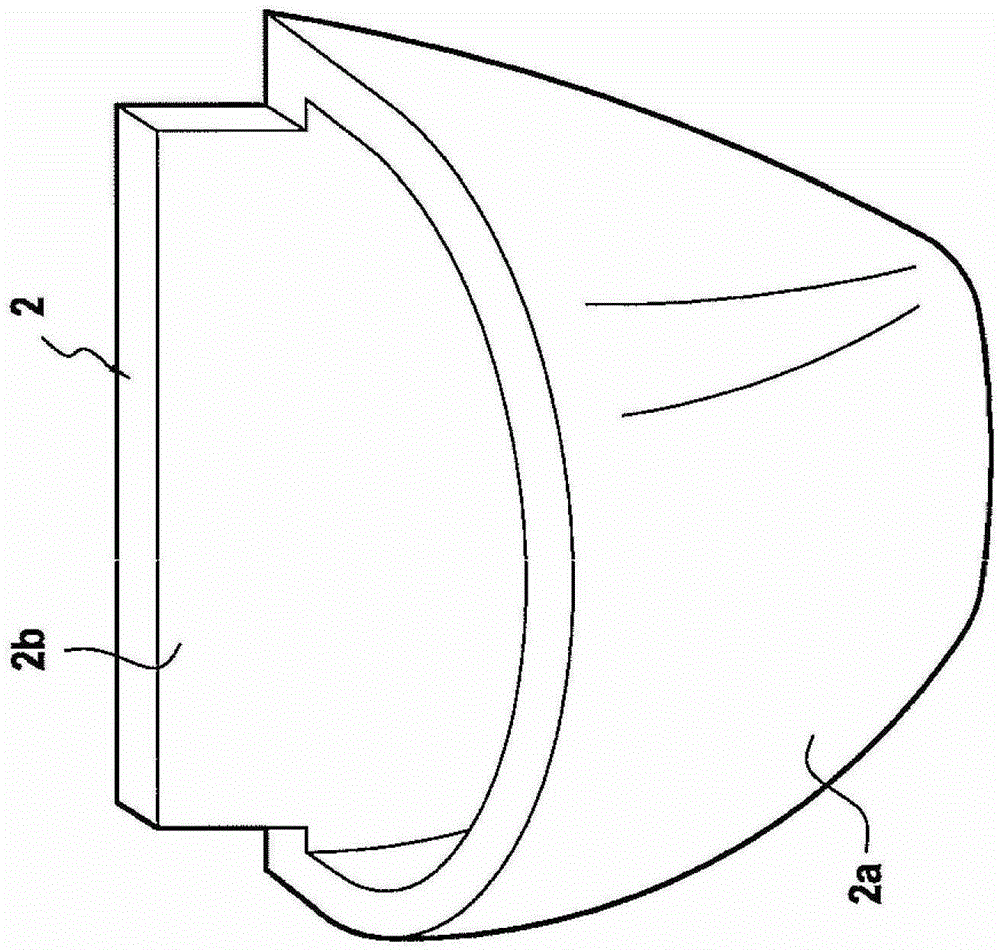

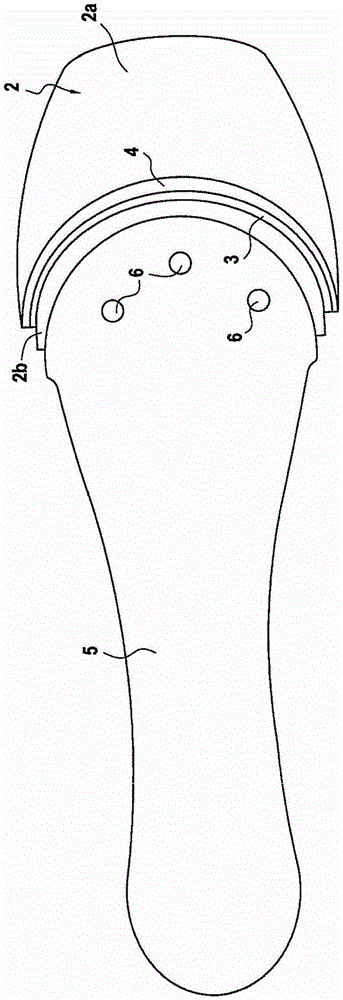

[0037] figure 1 is a schematic illustration of a variant of an embodiment of the protective element of the invention intended to be inserted into an article of footwear.

[0038] figure 1 To give an example of the general shape of this protective element with the housing 2, the housing 2 consists of a front part 2a; the front part 2a is specifically intended to receive the toes of a dancer, and this front part is extended into a rear part 2b.

[0039] In this example, the rear part 2b is in the shape of a tongue, which protrudes from the front part 2a.

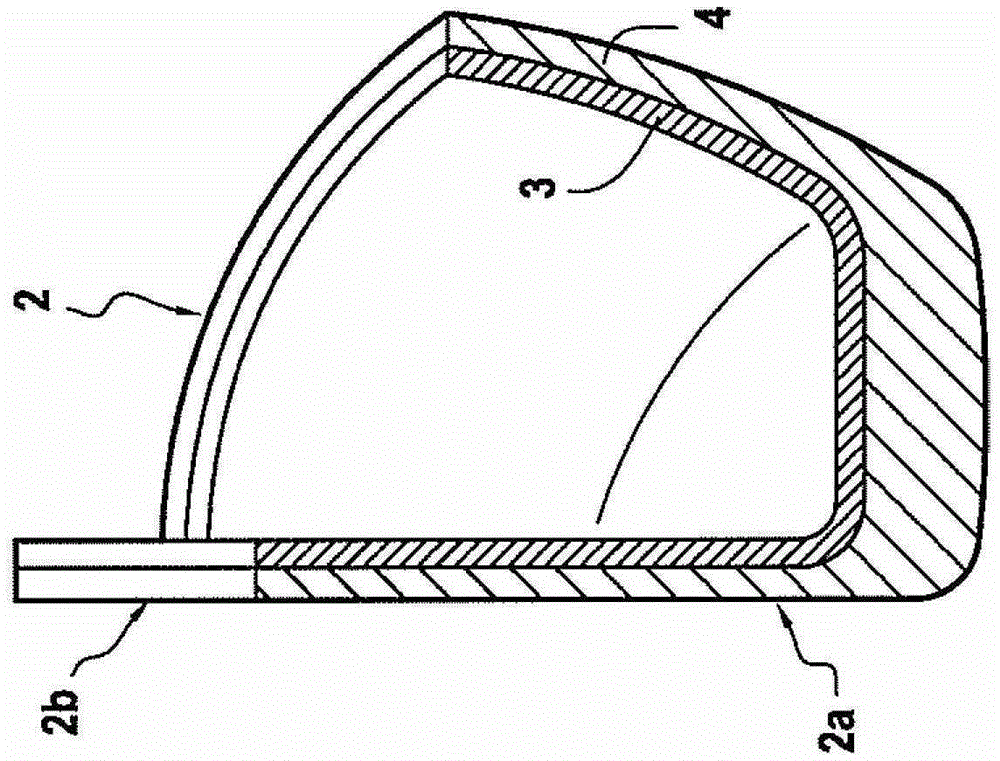

[0040] figure 2 show figure 1 Cutaway view of the middle part of the protective element.

[0041] exist figure 2 It can be seen that the housing 2 is provided with an inner part 3 intended to contact the dancer's toes and an outer part 4 facing opposite.

[0042] In this variant, the rear part 2 b of the housing 2 is itself provided with a part inner part 3 and part outer part 4 .

[0043] Alternatively, however, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com