Metal casting device

A technology of metal casting and driving device, applied in the field of metal casting of high melting point metal and metal casting device, can solve the problems of large body, damaged joint surface, poor contact, etc., and achieves the effect of simple structure, small size and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in conjunction with accompanying drawing and specific embodiment:

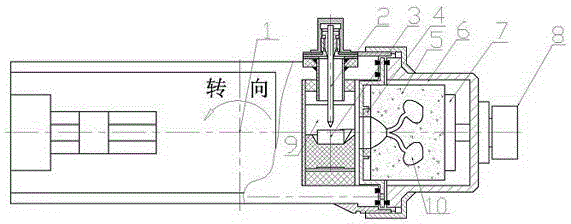

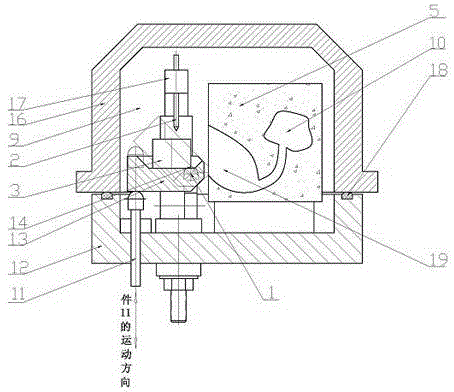

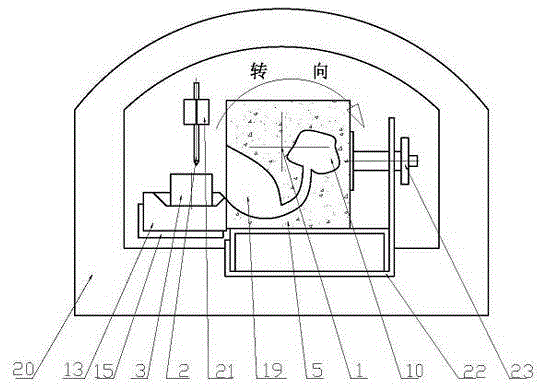

[0030] like image 3 , Figure 4 As shown, a metal casting device, the casting chamber 6 is formed between the shell 20 and the front door 29 of said metal casting device; The ring II 28 is used to ensure reliable sealing between the housing 20 and the front door 24; the crucible 13 and the casting mold 5 are arranged in the casting chamber 6; 19 is provided correspondingly; the casting mold 5 is placed on the casting mold support 22; the casting mold 5 has a storage chamber 19 and a casting molding cavity 10 for molding the casting; it is set above the crucible 13 for passing through Arc discharge is used to melt the tungsten pole 2 placed on the metal block 3 in the crucible; the tungsten pole 2 is fixed on the cathode shaft 21; the cathode shaft 21 is connected to the cable outside the housing 20 through the cathode insulating sleeve 26; the The crucible 13 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com