Bottom underwater cleaner for large vessels

A technology for cleaning equipment and ship bottoms, applied in ship cleaning devices, ship hulls, ship construction, etc., which can solve problems such as low cleaning efficiency, aggravating ship corrosion, and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] The present invention adopts a brand-new design idea from the system design. The system adopts the idea of modular design, which divides the equipment into multiple modules, which greatly improves the reliability and easy maintenance of the system.

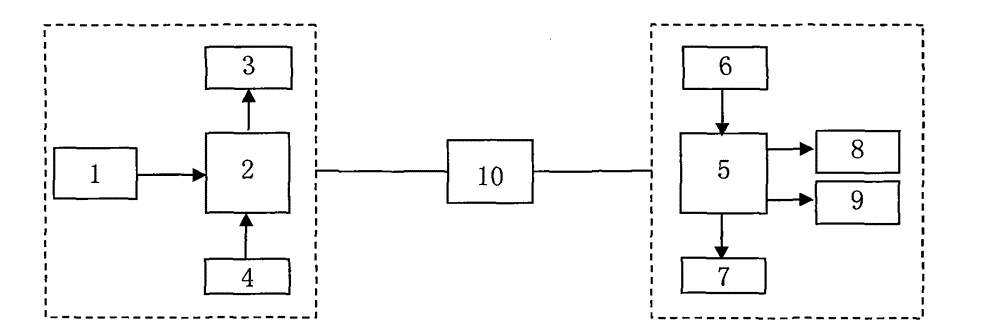

[0018] Such as figure 1 As shown, the underwater cleaning equipment for the large ship bottom is composed of three parts: the monitoring and control unit on the ship, the underwater cleaning unit and the connecting cable. The on-board monitoring and control unit is operated by the on-board staff. It is mainly composed of a display 3, a controller 2 and a key input module 4. It has image monitoring, underwater cleaning unit status monitoring and underwater cleaning unit control functions. The on-board monitoring and control unit controller 2 adopts the controller with Cortex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com