Treatment process of boiler dusting water

A boiler and treatment system technology, applied in the field of industrial wastewater treatment, can solve the problems of high concentration of turbidity suspended solids and CODcr in dust removal wastewater, affecting the environmental sanitation of the factory area, and inconvenient operation, etc., and achieves easy promotion, low cost, and convenient external use The effect of luck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

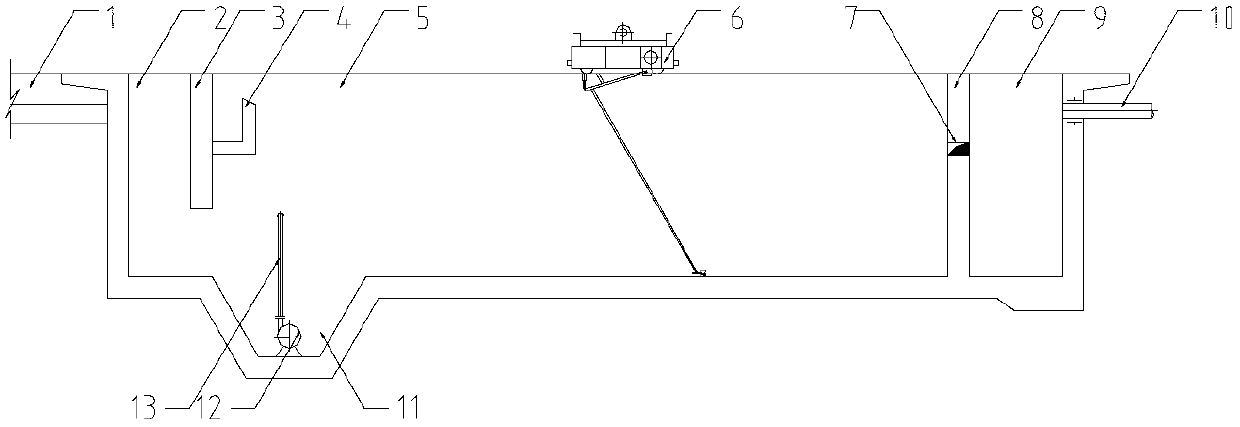

[0017] A treatment system for boiler dedusting water, comprising an advection ash settling tank and a clear water tank, the advection ash settling tank, such as figure 1 As shown, it is divided into rectification area 2, sedimentation area 5 and water outlet area 9; rectification wall 3 is set between rectification area 2 and sedimentation area 5; slag blocking wall 8 is set between sedimentation area 5 and water outlet area 9 The water passage hole 7; the sedimentation area 5 is equipped with a driving type mud scraper 6, the upper part of the head end of the sedimentation area 5 is equipped with a slag collection tank 4, the lower part is equipped with a mortar bucket 11, and a sludge discharge pump 12 is installed in the mortar bucket 11;

[0018] The surface load used in the advection ash settling tank is 0.7m 3 / m 2 h, the hydraulic retention time is 3.0h, the aspect ratio of the advection ash settling tank is 4.2, and the aspect ratio is 10.0.

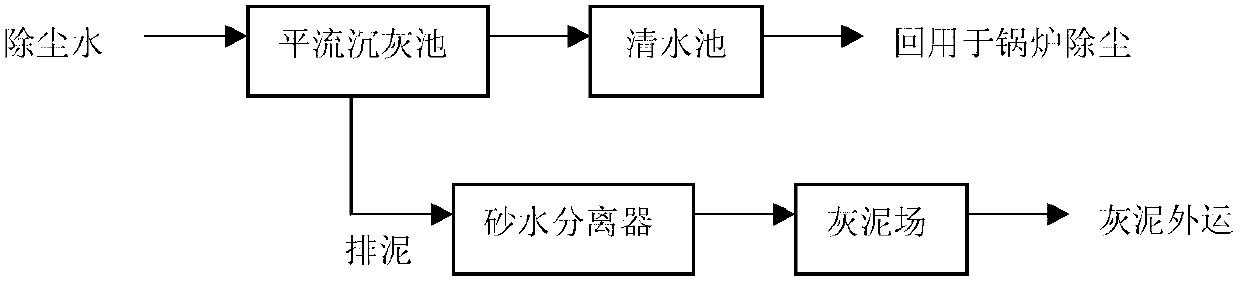

[0019] A treatment proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com