Preparation method and usage of special tea dye for silk

A technology of dyes and tea, applied in dyeing, azo dyes, organic dyes, etc., can solve the problems of special dye teas not being launched on a large scale, slow progress in tea dyeing research, low market awareness, etc., to achieve simple and elegant colors , broad market prospects, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

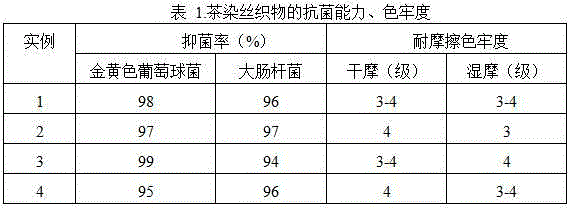

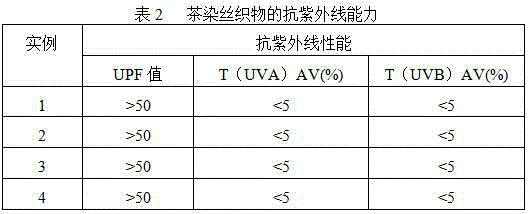

[0015] Example 1: Fix the color of fresh tea leaves at 200° C. for 2.0 minutes, knead and cut them, and directly add ethanol to extract the tea dye. During the extraction, the ratio of solid to liquid (weight ratio), extraction temperature and extraction time were controlled at 1:20, 50°C and 30 min, respectively, and filtered after the extraction was completed, so that the content of tea polyphenols in the dyeing liquor was above 0.3%; The dyeing solution was prepared at a bath ratio of 1:20, and the silk fabric was dyed at 50°C for 1 h, then dyed in 0.6% aluminum salt mordant solution for 1 h, finally washed with pure water, and dried into a yellow-green silk fabric.

Embodiment 2

[0016] Example 2: Fix the color of fresh tea leaves at 240°C for 1.0 min, knead and cut them, and directly add ethanol to extract the tea dye. The ratio of solid to liquid during extraction is the weight ratio, and the extraction temperature and extraction time are controlled at 1:15, 60°C and 30 min respectively. The liquor ratio is 1:20 to prepare the dye solution, and the silk fabric is dyed at 50°C for 1 h, then dyed in 0.6% aluminum salt mordant solution for 1 h, finally washed with pure water, and dried to yellow-green silk fabric.

Embodiment 3

[0017] Example 3: Fix the color of fresh tea leaves at 220° C. for 1.5 minutes, knead and cut them, and directly add sodium carbonate to extract the tea dye. The ratio of solid to liquid during extraction is the weight ratio, and the extraction temperature and extraction time are controlled at 1:20, 60°C and 35 min respectively. The dyeing solution was prepared at a ratio of 1:20, and the silk fabric was dyed at 60°C for 1 h, then dyed in 0.6% copper salt mordant solution for 1 h, finally washed with pure water, and dried to obtain a champagne-colored silk fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com