Low-alkalinity synthetic slag for external refining of boiler tube steel

A technology of synthetic slag and low basicity, applied in the field of steelmaking, can solve the problems of poor oxidation resistance, not strictly controlling the FeO+MnO content of the refining synthetic slag, and poor inclusion capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

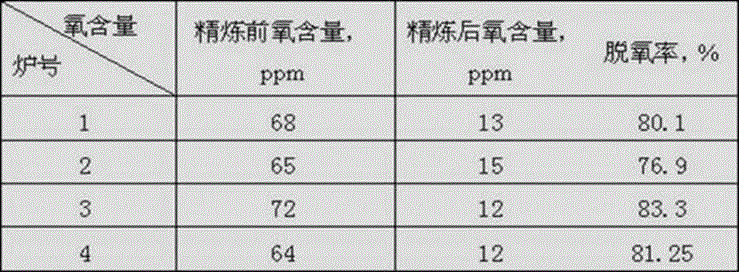

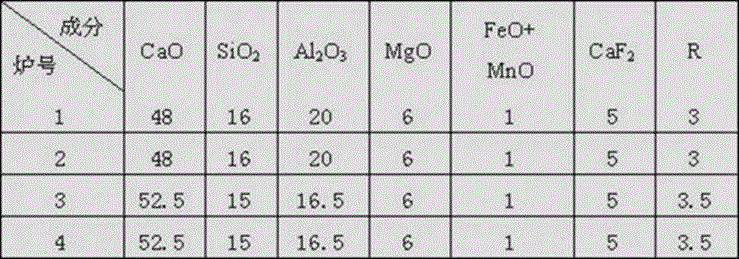

[0018] According to the chemical composition range described in the present invention, 4 batches of high alkalinity synthetic slags were prepared. Using synthetic slag in a 10kg vacuum induction furnace, four heats of molten steel were refined. According to the batch number of the synthetic slag, it is added to the molten steel of the corresponding furnace number. After the synthetic slag is added, blow argon and stir the molten steel for 15 minutes, then add silicon-calcium wire for calcium treatment, blow argon and stir weakly for 8 minutes before pouring the ingot. Steel samples were taken from the molten steel before the refining slag was added and from the final ingot. The total oxygen content of the steel samples was analyzed, and the morphology and composition of inclusions in steel were analyzed by scanning electron microscope (SEM) + energy dispersive spectroscopy (EDS); the morphology and quantity of inclusions in steel were analyzed by optical microscope. The resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com