Method for draining roof water in flood mine

A large water mine, water drainage technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve the problems of increased drainage difficulty, increased separation of water and coal in underground water tanks, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

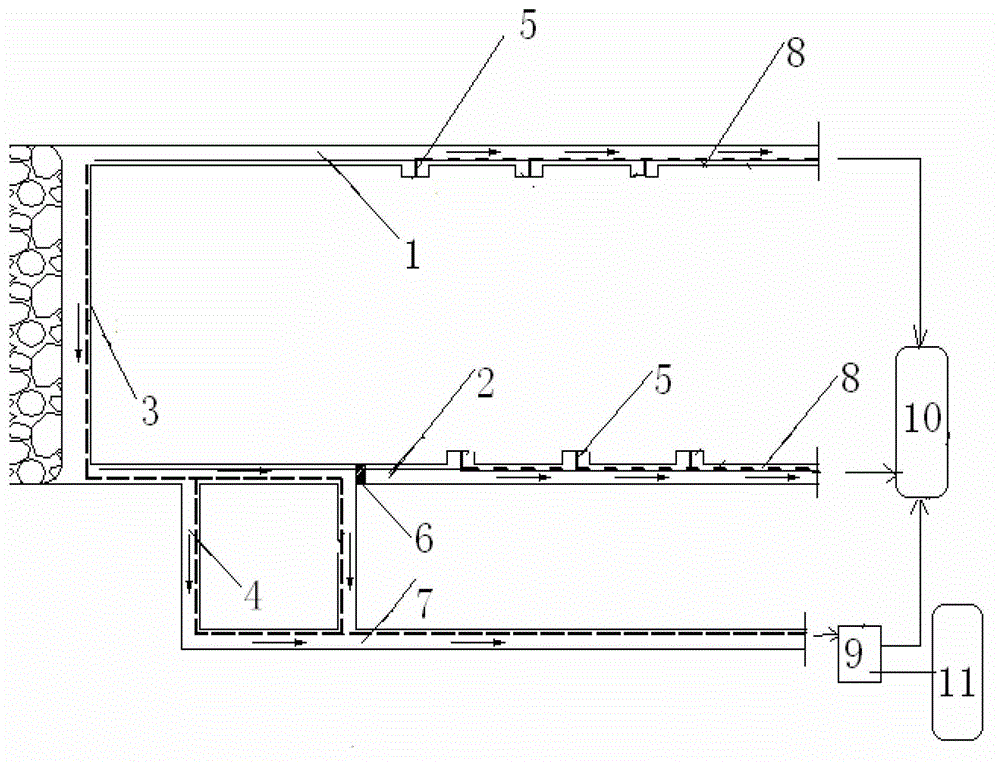

[0018] Such as figure 1 Shown, the technical scheme of the large water mine roof water discharge method of the present invention is:

[0019] 1. Before mining at the working face 3, first construct drainage ditches 8 in the upper track lane 1 and the lower belt lane 2, and set up water storage drill holes 5 at certain distances; develop a line below the belt lane 2 parallel to the belt lane 2 Water-coal body separation facilities 9 are set up at the end of the drainage channel 7, through-holes 4 are set up at regular distances in the belt lane 2, and the belt lane 2 is connected with the drainage channel 7 through the through-holes 4, and set at the through-hole Water retaining structure 6;

[0020] The above-mentioned water-coal body separation facility 9 may be a sedimentation tank or a vibrating screen.

[0021] 2. Then according to the traditional method, in the upper track lane 1 and the lower belt lane 2, drain holes are arranged to the roof of the coal seam, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com