Alcohol-free offset-printing fountain solution

A fountain solution and alcohol-free technology, which is applied in the field of offset printing, can solve the problems of potential safety hazards, high volatility, low flash point, etc., and achieve the effects of improving printing effect, zero VOC emissions, and reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] The mass percent of each component is:

[0025] Ion-exchanged water 20% acid-base regulator 4.5% sodium carboxymethyl cellulose 3% environmental solvent 70% surfactant 2% preservative 0.5%

specific Embodiment 2

[0026] The mass percent of each component is:

[0027] Ion exchanged water 40%

[0028] Acid-base regulator 3.5%

[0029] Sodium Carboxymethyl Cellulose 5%

[0030] Environmentally friendly solvent 48%

[0031] Surfactant 2.5%

[0032] Preservatives 1%

specific Embodiment 3

[0033] The mass percent of each component is:

[0034] Ion exchanged water 50%

[0035] Acid-base regulator 3%

[0036] Sodium Carboxymethyl Cellulose 8%

[0037] Environmentally friendly solvent 35%

[0038] Surfactant 3%

[0039] Preservatives 1%

[0040]

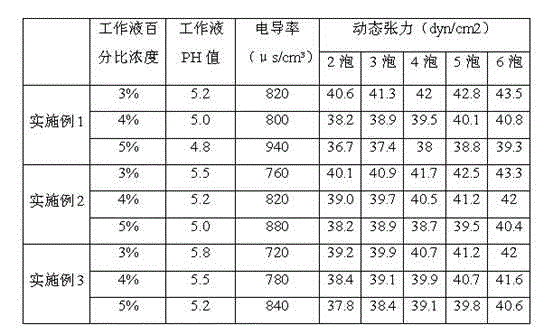

[0041] Table 1

[0042] The data parameter detection results of each embodiment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com