Novel active sludge process with reduced excess sludge

A technology of activated sludge and excess sludge, applied in water/sludge/sewage treatment, aerobic process treatment, chemical instruments and methods, etc. High operating costs and other issues, to achieve the effect of convenient management, low pollution, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

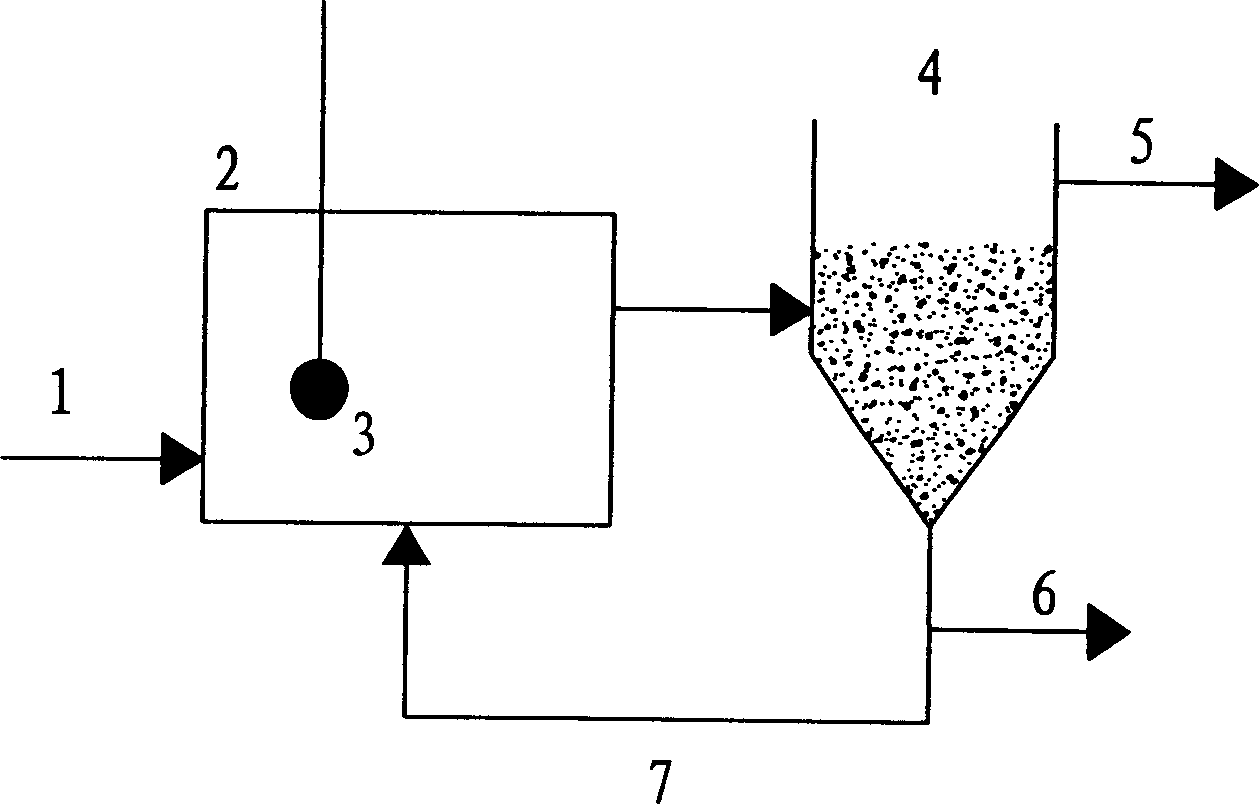

[0029] Embodiment 1: the activated sludge process that this test adopts is the fully mixed activated sludge process of laboratory scale, and the effective volume of aeration tank is 12.5L, and the effective volume of settling tank is 2.2L (see attachment figure 1 ). There are 2 sets of test devices in total. Both devices are inoculated with 10 grams of activated sludge from the secondary settling tank of Ningbo Wastewater Treatment Plant, and input domestic sewage of the same water quality (COD is 600mg / L, BOD 5The total nitrogen concentration is 260mg / L, the total nitrogen concentration is 80mg / L, and the ammonia nitrogen concentration is 40mg / L), and the total amount of domestic sewage treated daily is 36 liters. The aeration tank is continuously aerated, the mud-water mixture in the aeration tank enters the sedimentation tank, and all the sludge in the sedimentation tank flows back into the aeration tank, so that the sludge concentration (MLSS) in the aeration tank gradual...

Embodiment 2

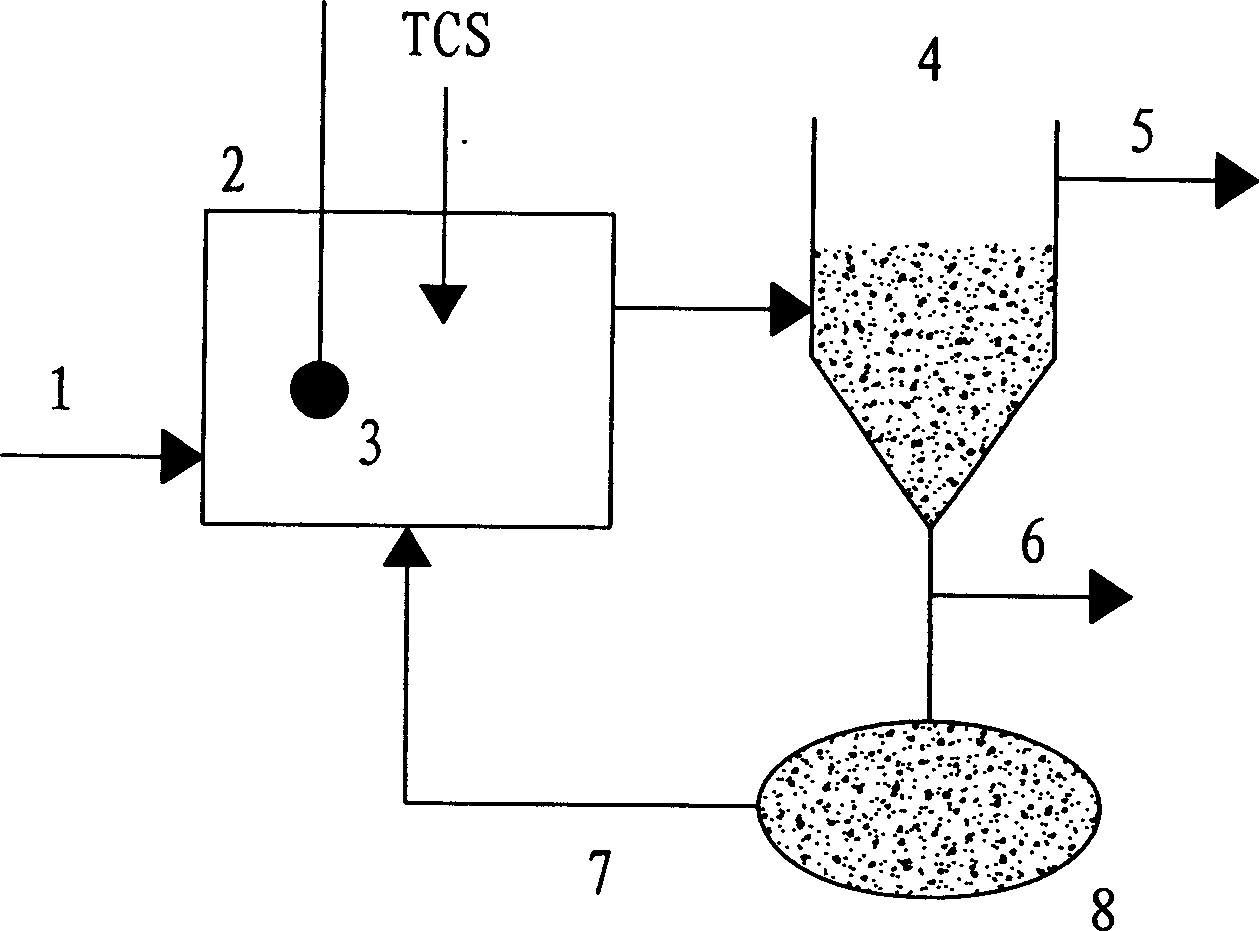

[0031] Embodiment 2: Different from Example 1, in the new process device of activated sludge, TCS 30mg is added to the aeration tank every day (the concentration in the aeration tank is 2.4mg / L), and the return sludge is in anoxic state. Pool stay 5.6 hours. The sludge yield of the activated sludge new process of this embodiment can be reduced by 39% compared with the traditional activated sludge process device, and the output water quality of the two sets of devices is almost the same, all reaching the discharge standard stipulated by the state, and the settling performance of the sludge is comparable to that of the control The traditional process is the same (SVI values are all less than 100), and the TCS in the effluent is checked by high performance liquid chromatography, and it is found to be zero.

Embodiment 3

[0032] Embodiment 3: Different from Example 1, in the new process device of activated sludge, TCS 40mg is added to the aeration tank every day (the concentration in the aeration tank is 3.2mg / L), and the returning sludge is in anoxic state. Pool stay 5.6 hours. The sludge yield of the activated sludge new process of this embodiment can be reduced by 42% compared with the traditional activated sludge process device, and the output water quality of the two sets of devices is almost the same, all reaching the discharge standard stipulated by the state, and the settling performance of the sludge is comparable to that of the control The traditional process is the same (SVI values are all less than 100), and the TCS in the effluent is checked by high performance liquid chromatography, and it is found to be zero (see Table 2).

[0033] Sludge yield

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com