Method for predicting transient fluid-solid coupling characteristic of centrifugal pump rotor

A fluid-solid coupling and characteristic prediction technology, which is applied in pump control, non-variable pumps, machines/engines, etc., can solve the problems of no experimental verification steps, unpredictable accuracy, etc., and achieve the effect of flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

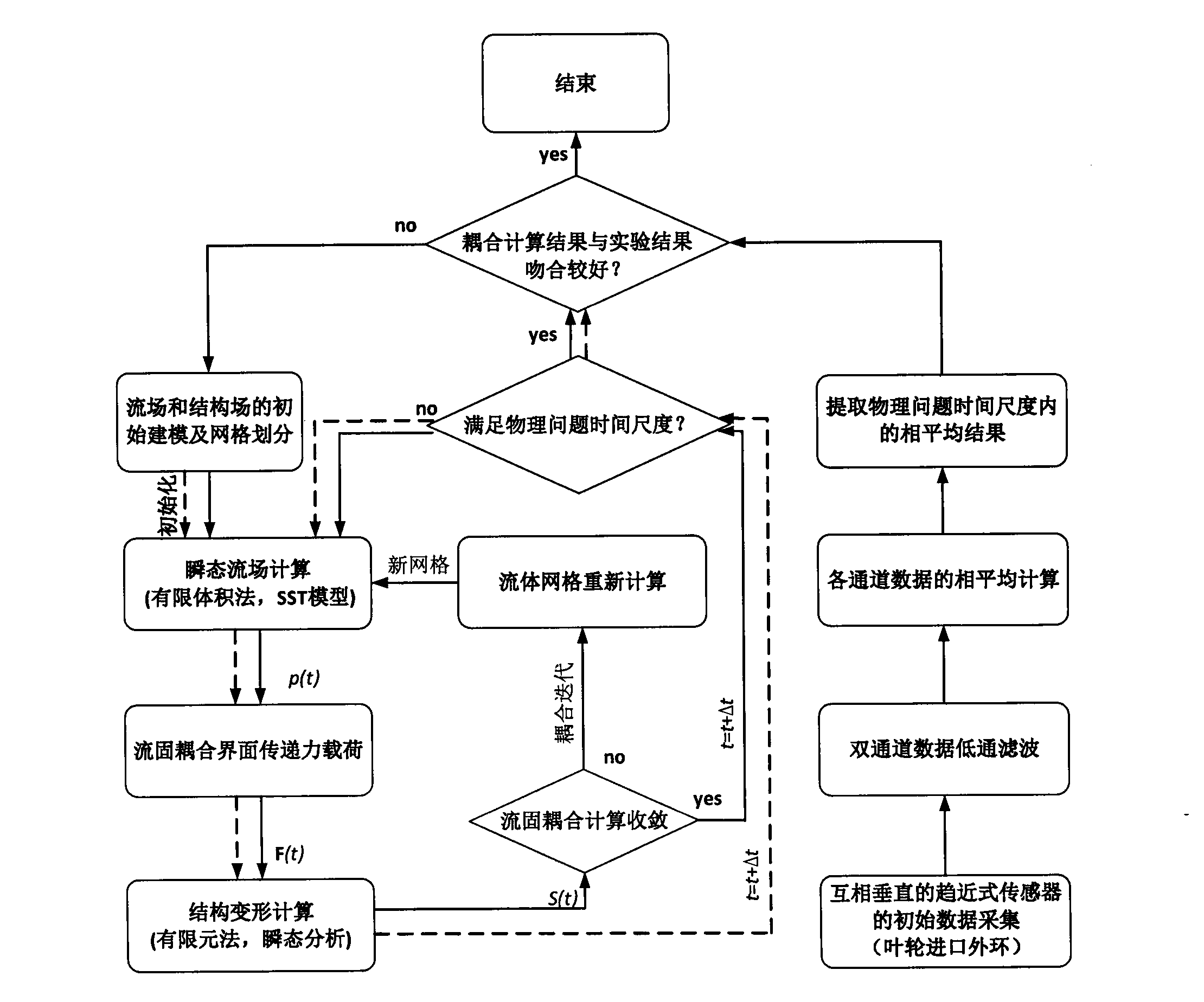

[0016] Below in conjunction with application example accompanying drawing, the present invention will be further described:

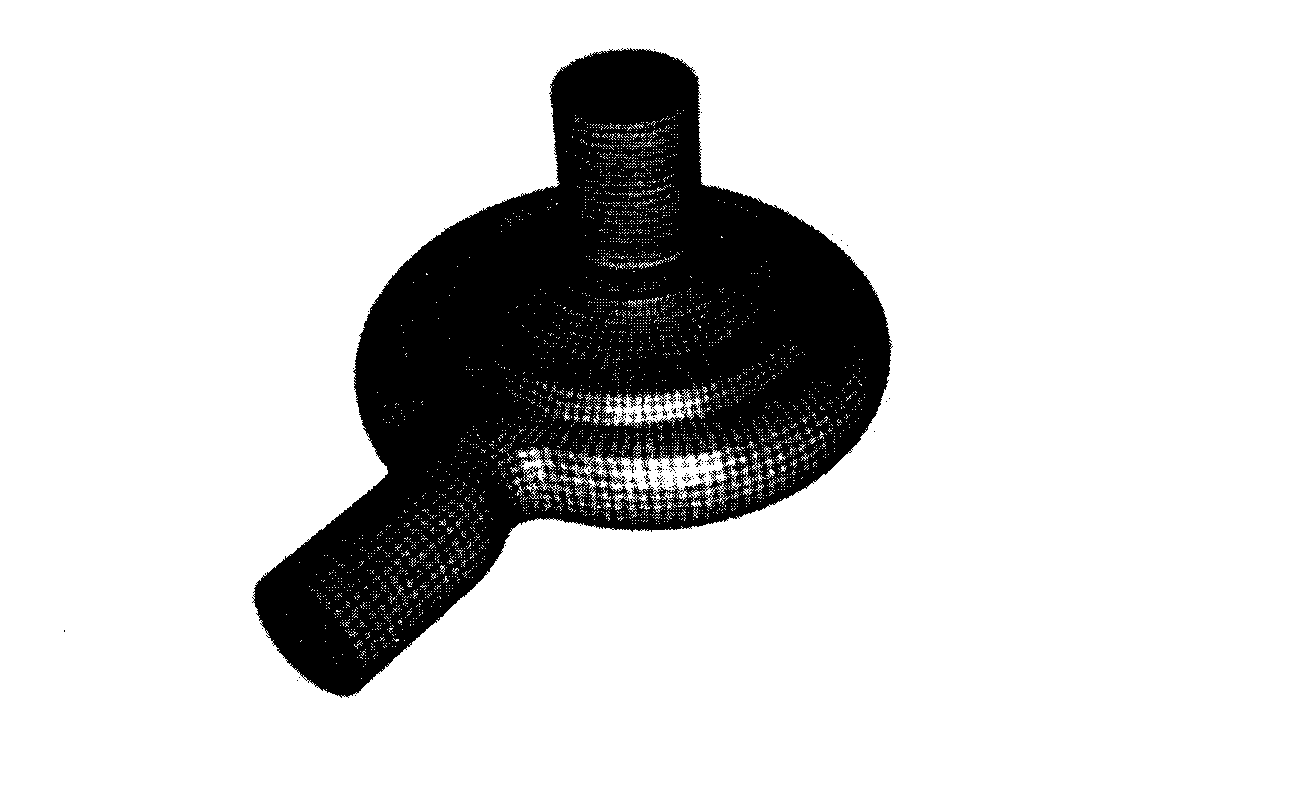

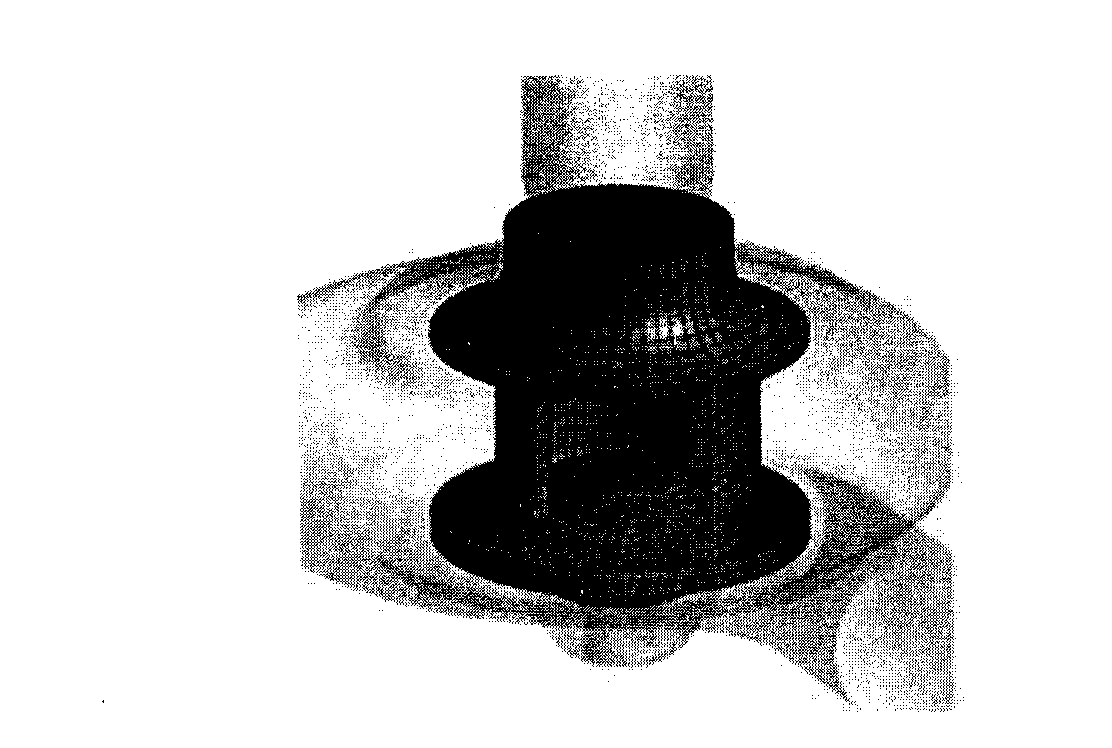

[0017] Such as figure 1 As shown, the method for predicting the fluid-structure coupling vibration characteristics of centrifugal pump rotors includes three steps: Step 1: Calculation of transient fluid-structure coupling in one-way and two-way full flow fields; Step 2: Measurement and processing of rotor vibration data; Step 3: Flow Comparison of solid-coupling numerical prediction results with experimental results. Step 1 includes 1.1 initial modeling and grid division of flow field and structure field; 1.2 transient simulation of flow field based on SST turbulence model; 1.3 load transfer process at fluid-solid coupling interface; 1.4 structural dynamics based on finite element method 1.5 Judgment of convergence of fluid-solid coupling calculation; 1.6 Recalculation of fluid grid; 1.7 Physical time identification of coupling calculation. Step 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com