Simple method for rapidly testing restrained expansion rate of calcium sulphoaluminate expanding agent

A technology of calcium sulfoaluminate and expansion limitation, which is applied in the field of rapid testing of expansion rate limitation of calcium sulfoaluminate expansion agents, which can solve the problem of yellow sand and gravel with different mud content and chemical composition, which cannot meet the national standard Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

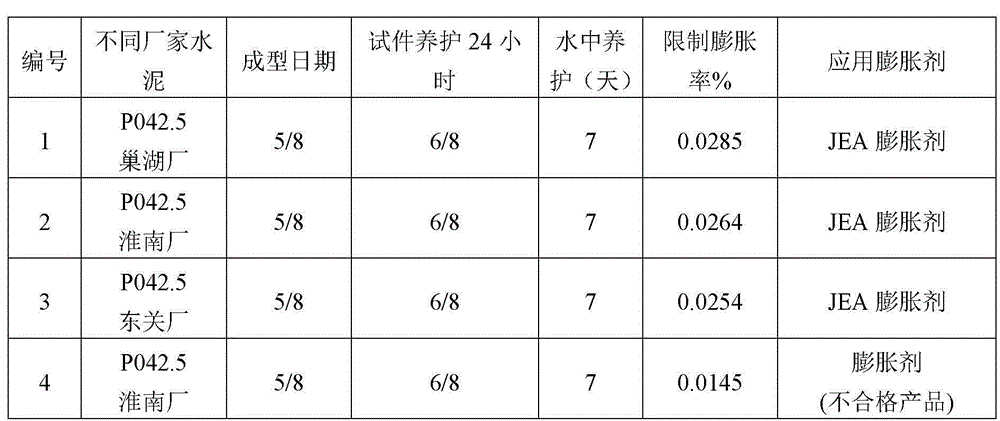

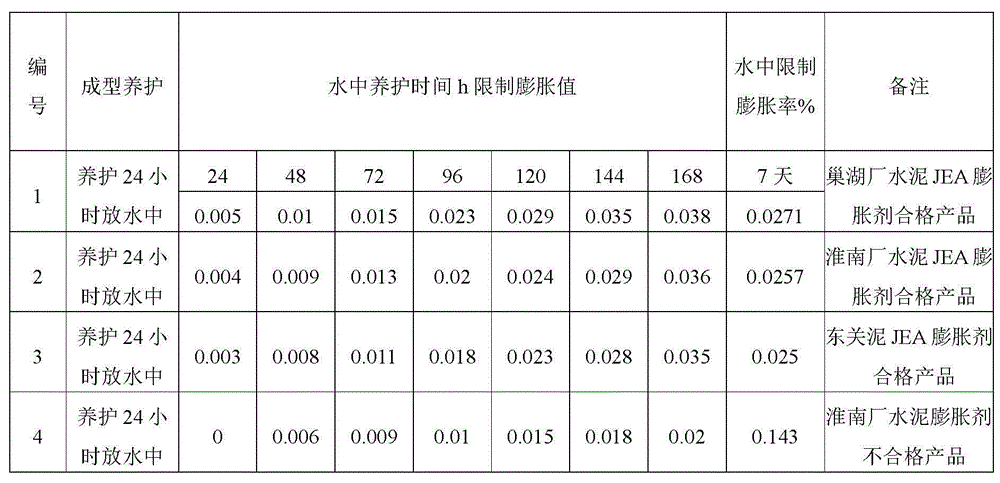

Examples

Embodiment Construction

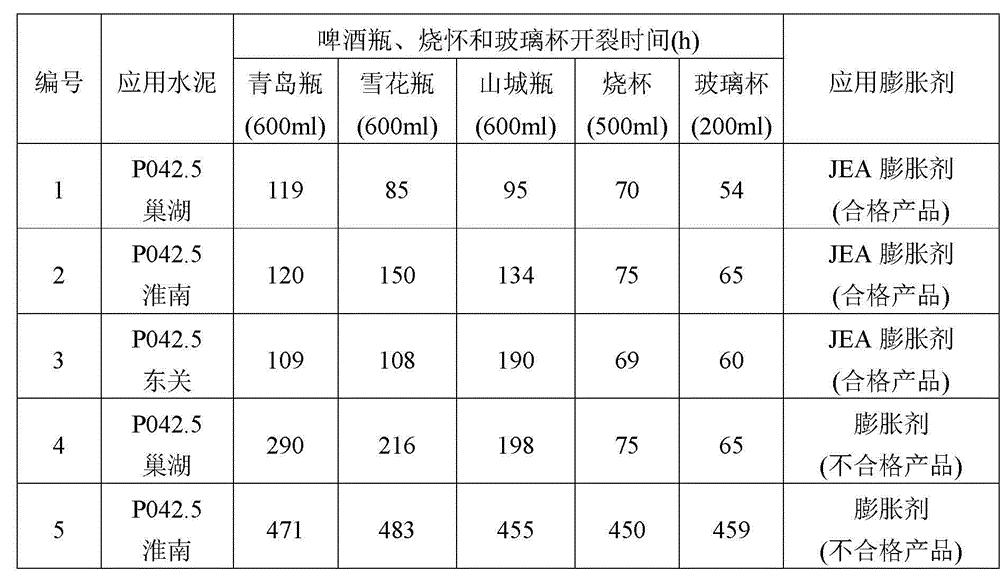

[0017] A simple method for quickly testing the limited expansion rate of calcium sulfoaluminate expansion agents is carried out according to the following steps:

[0018] Sampling is made from the concrete mixing material mixed with expansion agent on site to make cement expansion agent mortar. After sieving with Φ5mm to remove gravel, put it into three beer bottles with the same volume of 600ml respectively using funnels. The filling capacity of each beer bottle The input amount is 700g, and the bamboo slices (3-4mm thick, 9-10mm wide, 600mm long) are gently inserted and compacted, placed on a table with a towel and vibrated, and the cement in the beer bottle is observed to expand After the surface of the agent mortar layer is basically flat and grouted, stop the vibration, park it indoors for 24 hours, add 200 ml of water to each bottle, start counting, and check it every 4 hours to observe the expansion and cracking time of each beer bottle. If there are at least two beer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com