High-ripple resistant aluminium electrolytic capacitor

An aluminum electrolytic capacitor, ripple technology, applied in the direction of capacitor terminals, capacitor parts, etc., can solve the problems of capacitor heating, limit the service life of capacitors, increase the equivalent series resistance of capacitors, etc., to prolong the service life, reliable performance, Effect of Low Equivalent Series Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

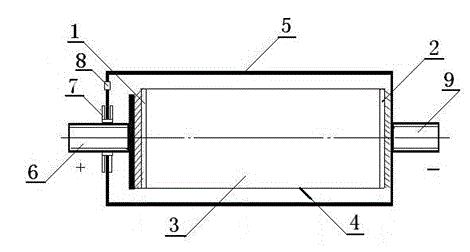

[0012] Example: see attached figure 1 , the present invention relates to a large ripple resistant aluminum electrolytic capacitor, comprising a positive electrode piece 1, a negative electrode piece 2, a separator paper 3, a core package 4 and an aluminum shell 5, a positive lead-out terminal 6, an insulating device 7, a safety explosion-proof device 8, and a negative electrode The lead-out terminal 9; the separator paper 3 is between the positive electrode sheet 1 and the negative electrode sheet 2, and the three are rolled together into a core package 4 and the core package 4 is installed in the aluminum casing 5 and connected to the aluminum casing 5 by ultrasonic welding or Laser welding; the positive lead-out terminal 6 is drawn from the left side of the aluminum shell 5 and the positive lead-out terminal 6 is isolated from the aluminum shell by an insulating device 7, while the negative lead-out terminal 9 is drawn from the right side of the aluminum shell 5 and the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com