Unpaired weldment lead-acid battery pack

A battery pack and butt welding technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of waste of battery space, complex production process, low volume density, etc. The effect of high battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

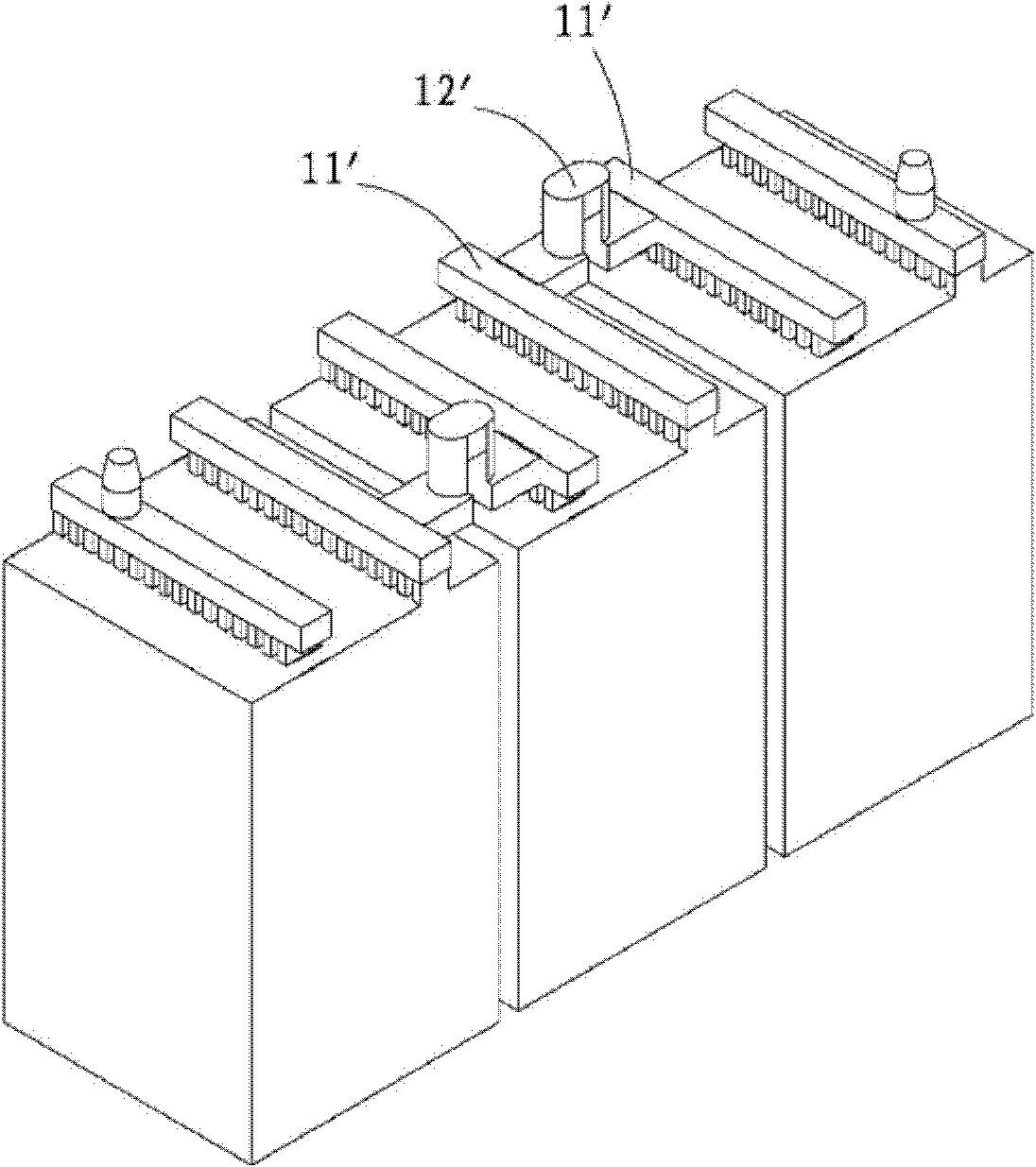

[0034] In this embodiment, more than two single cells 1 are arranged in a row and connected back and forth. Please refer to Figure 4 to Figure 6, which are respectively 2, 3, and 4 single-cell batteries 1 arranged in a single row and connected to form a schematic structural diagram of a 4V, 6V, and 8V lead-acid battery pack. The connecting bus 2 is at least one combined bus bar 121, and the combined The bus bar 121 is integrally formed by connecting two conventional bus bars 11 through an intermediate bus bar 12 . In this embodiment, the material and structure of the intermediate bus bar 12 are the same as those of the conventional bus bar 11, and it plays a connection role between the two conventional bus bars 11, and the integrated combined bus bar 121 has better connection characteristics , so that the internal resistance of the battery is lower, and the ability to carry current is stronger; at the same time, the biggest advantage of this single-row arrangement in this emb...

Embodiment 2

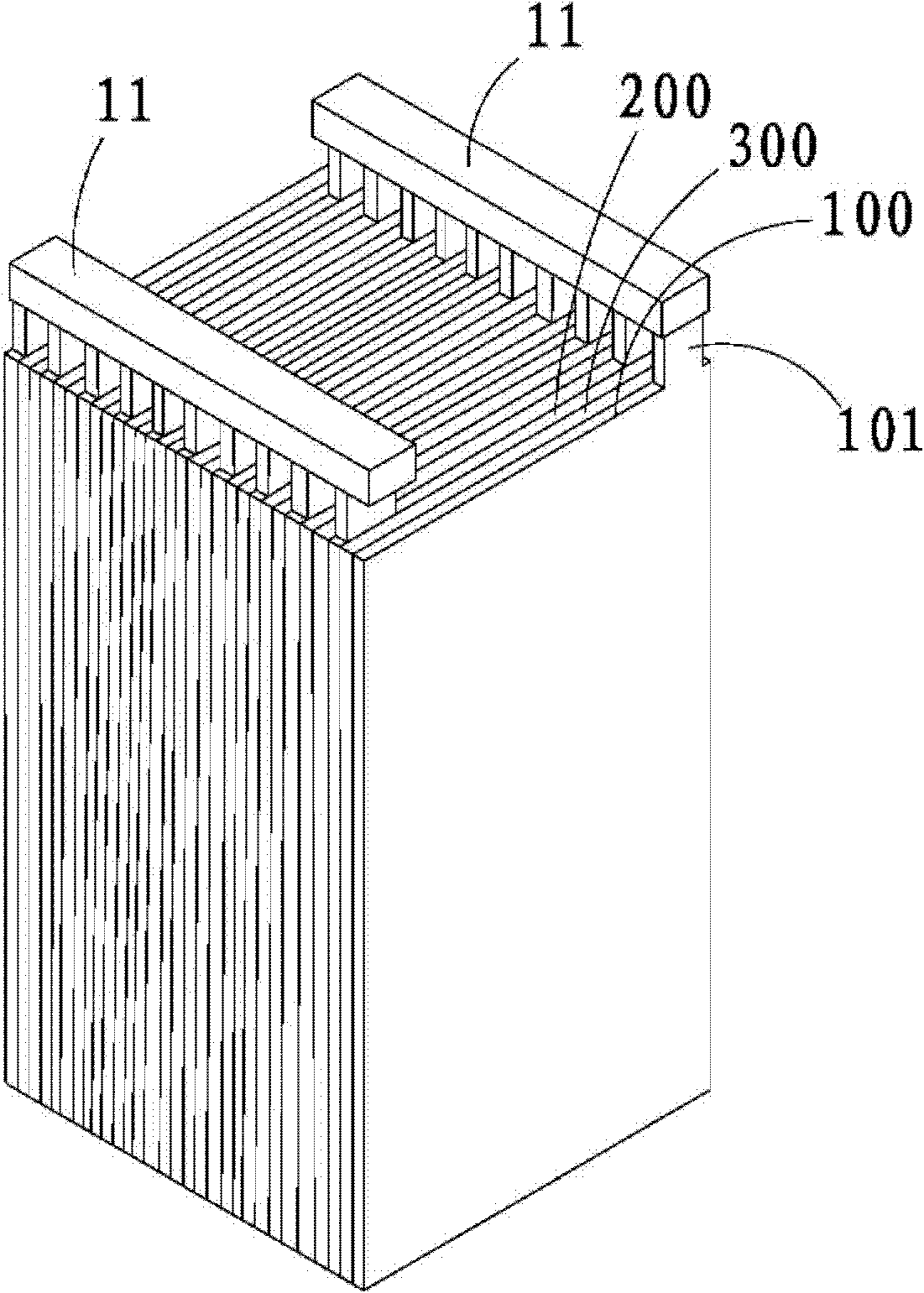

[0036] In this embodiment, more than two single cells 1 are arranged in a row side by side and connected side by side. Please refer to Figure 7 to Figure 9 , are respectively 2, 3, and 4 single-cell batteries 1 arranged side by side in a single row to form a structural schematic diagram of a 4V, 6V, and 8V lead-acid battery pack, and the connecting bus bar 2 is at least one extended bus bar 111, The extended bus bar 111 is in the shape of a "one" and integrally formed. The structure of the extended bus bar 111 is the same as that of the conventional bus bar 11, which is equivalent to two conventional bus bars 11 connected end to end and integrally formed. The advantage of this single-row arrangement in this embodiment is that the thickness of the entire battery pack can be the thickness of the single battery 1 itself, so that it is suitable for some applications that require the thickness of the battery pack. At the same time, this In the connection mode, the structure of the...

Embodiment 3

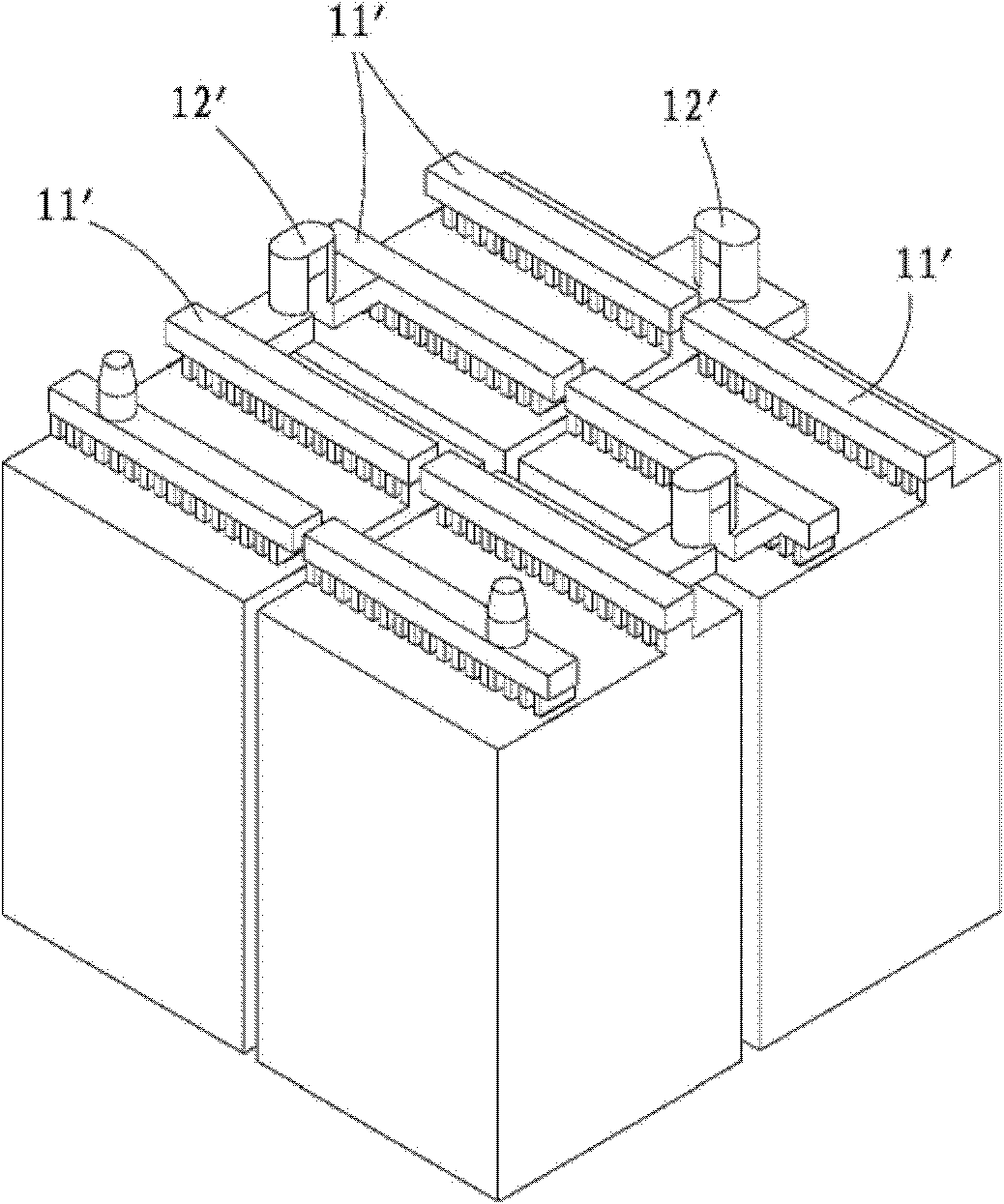

[0038] In this embodiment, more than four single cells 1 are grouped and then connected side by side and arranged in front and back. Please refer to Figure 10 to Figure 14 , which are respectively 4, 6, 8, and 9 single cells 1 compositely arranged and connected to form a structural diagram of a lead-acid battery pack of 8V, 12V, 16V, and 18V, and the connecting bus bar 2 is at least one combined bus bar row 121 and at least one extended bus bar 111. The combined bus bar 121 is formed by connecting two conventional bus bars 11 through an intermediate bus bar 12 and integrally formed. The extended bus bar 111 is in the shape of a "one" and is Formed integrally, the structure of the elongated bus bar 111 is the same as that of the conventional bus bar, which is equivalent to two conventional bus bars 11 connected end to end and formed integrally. The arrangement and connection mode between the single cells 1 in this embodiment is a combination of two different arrangement and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com