Production process of hot pickled mustard tubers and hot pickled mustard tuber

A production process and technology of pickled mustard, which is applied in the production process of mustard mustard and the field of mustard mustard, can solve the problems of unfavorable development of air-dried mustard mustard, unqualified quality of mustard mustard, and poor taste, so as to reduce product quality risks, improve capital use efficiency, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

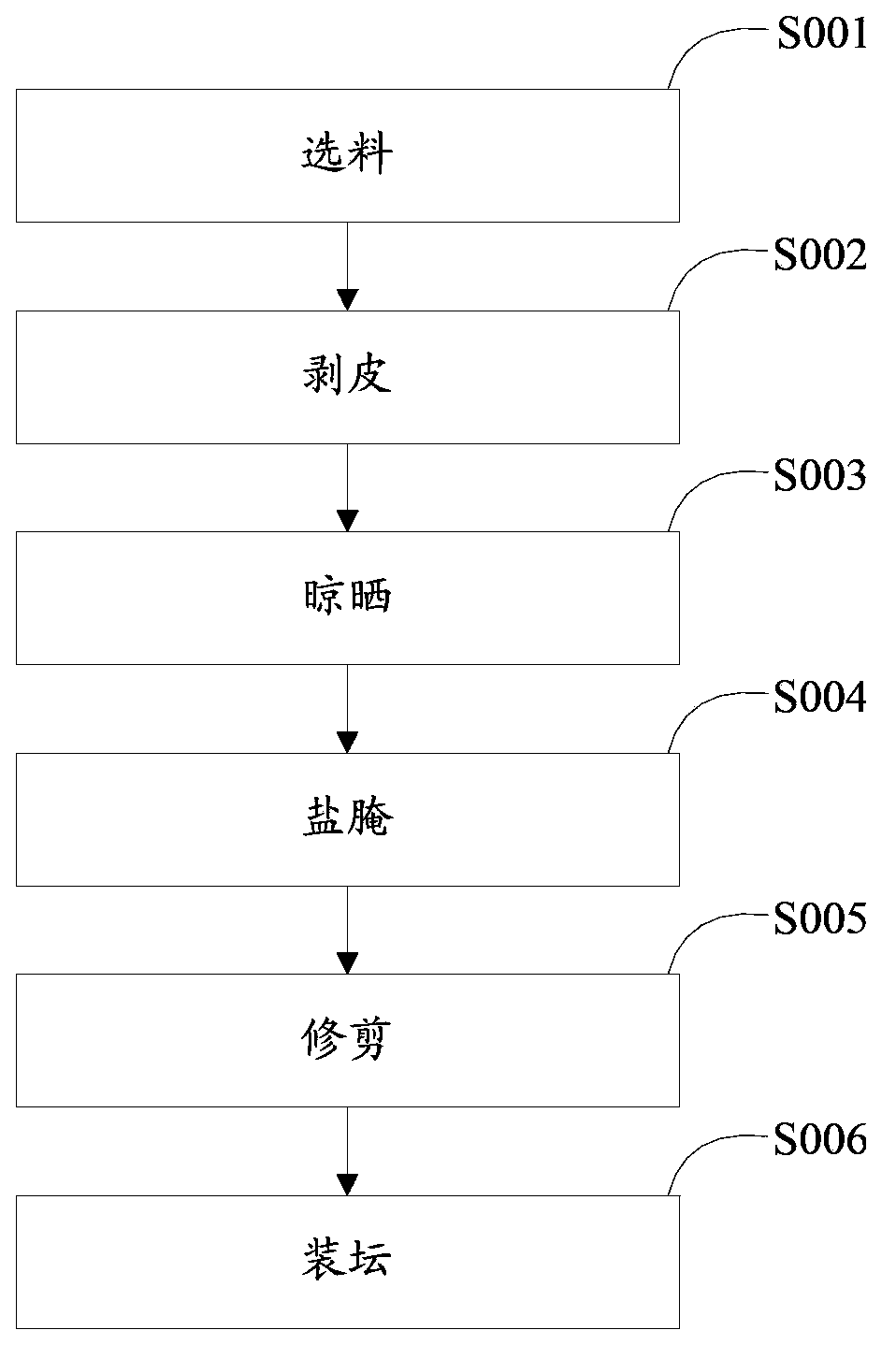

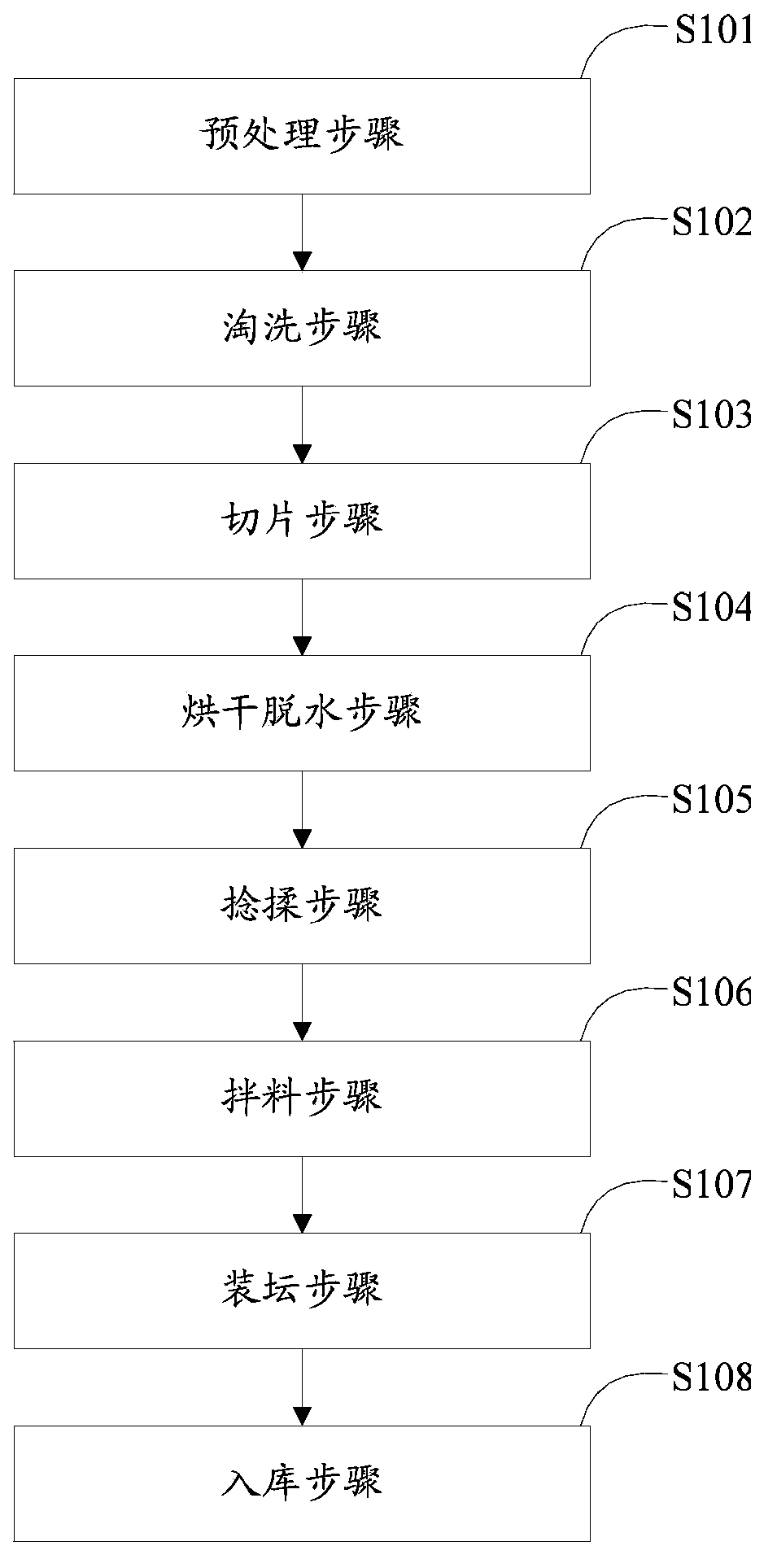

[0041] see figure 2 Shown, the production technology of the pickled mustard of the embodiment of the present invention comprises the following steps:

[0042] S101. Pretreatment step (selection, skinning and tendon repairing process).

[0043](1) Quality requirements: raw materials after selection, peeling and tendon repair. a. No hair, mildew, blackening, deterioration, and odor; b. No black spots, rotten spots, impurities, and foreign objects; c. No old tendons, impurities, and a qualified rate of pruning ≥ 98%.

[0044] (2) Working methods:

[0045] Pour the raw mustard mustard into the pruning pot, and select them one by one. Select the black spots, rotten spots, pink cabbage, sugar cabbage, arrow stalk vegetables, sour, lingering, mildewed vegetables and impurities in the raw materials. The old tendon on the vegetable is gradually peeled upward from the root of the vegetable, and the flying skin on the surface of the vegetable is cut off, and the black spots and rotte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com