Method for preparing whey protein powder (WPC) and lactose powder simultaneously by whey

A technology of whey protein powder and lactose powder, which is applied in food preparation, protein food ingredients, milk protein ingredients, etc., can solve the problem of failing to meet the standard requirements of concentrated whey protein, low whey protein protein content, and lack of concentrated whey protein Whey protein and other issues, to achieve the effect of reducing the amount of sewage treatment, reducing energy consumption, and reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

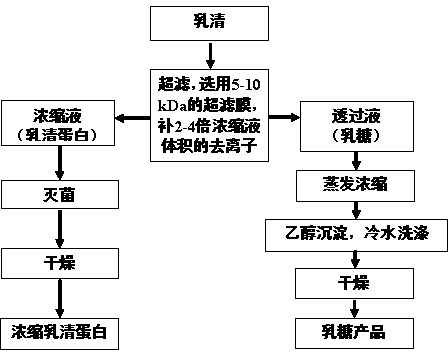

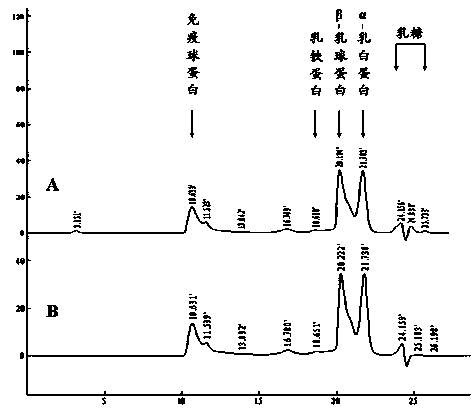

[0034] Example 1 (Preparation of Whey Protein Powder WPC 70 and Lactose from Sweet Whey Powder)

[0035] Weigh 182.9 g of sweet whey powder, add water to dissolve to 2 L, adopt a molecular weight cut-off of 10,000 Da, and a membrane area of 0.11 m 2 The polyethersulfone membrane ultrafiltration, transmembrane pressure 0.24 MPa, membrane surface flow rate 36 L / h, ultrafiltration until the membrane flux is 80% of the initial membrane flux, the remaining concentrated solution is about 170 mL, start continuous water replenishment, replenish water The speed is roughly equal to the ultrafiltration speed, and the volume of the concentrate is kept basically unchanged. A total of 2.6 times the volume of the concentrate (about 450 mL) of deionized water was added to obtain 2425 mL of permeate and 180 mL of concentrate.

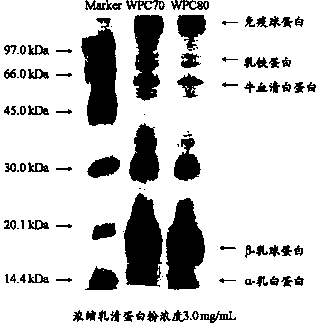

[0036] The ultrafiltration concentrate was directly freeze-dried to obtain 20.49 g of light yellow whey protein powder, the protein content (by dry weight) was 73.57...

Embodiment 2

[0038] Example 2 (Extraction of whey protein concentrate WPC 80 from whey powder)

[0039] Weigh 180.6 g of sweet whey powder and dilute to 2 L. The operating conditions of diafiltration are roughly the same as in Example 1, except that when the membrane flux is 60% of the initial membrane flux by ultrafiltration, the remaining concentrated solution is about 170 mL, and about 1500 mL of water (about 5 times the volume of the concentrated solution) is started, Finally, 3285 mL of permeate and 170 mL of concentrate were obtained.

[0040] The ultrafiltration concentrate was freeze-dried to obtain 14.89 g of light yellow whey protein powder, the protein content (by dry weight) was 81.74%, the lactose content was 1.97%, the fat content was 4.23%, the moisture content was 7.02%, the ash content was 3.85%, and the main metal The ion content is: potassium 470.4 mg / 100g, sodium 233.6 mg / 100g, calcium 1117 mg / 100g, magnesium 86.0 mg / 100g, copper 1.32 mg / 100g, zinc 1.10 mg / 100g, mangan...

Embodiment 4

[0042] Example 4 (separation of lactose by ultrafiltration without replenishment)

[0043] Prepare 150 mL of 10 g / L sweet whey powder solution with deionized water, and pass through a regenerated cellulose membrane with a molecular weight cut-off of 5000 Da in a millipore ultrafiltration cup, and perform ultrafiltration under 0.2 MPa nitrogen, without adding water during the ultrafiltration process. The concentrations of lactose in the raw material, concentrate and permeate were determined to be 7.60 g / L, 7.53 g / L and 7.60 g / L, respectively. Since the lactose molecule is small enough to freely shuttle through the membrane pores, the way it passes through the membrane pores is free diffusion, and the driving force is the concentration difference, so ultrafiltration cannot separate lactose from raw materials without replenishing water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com