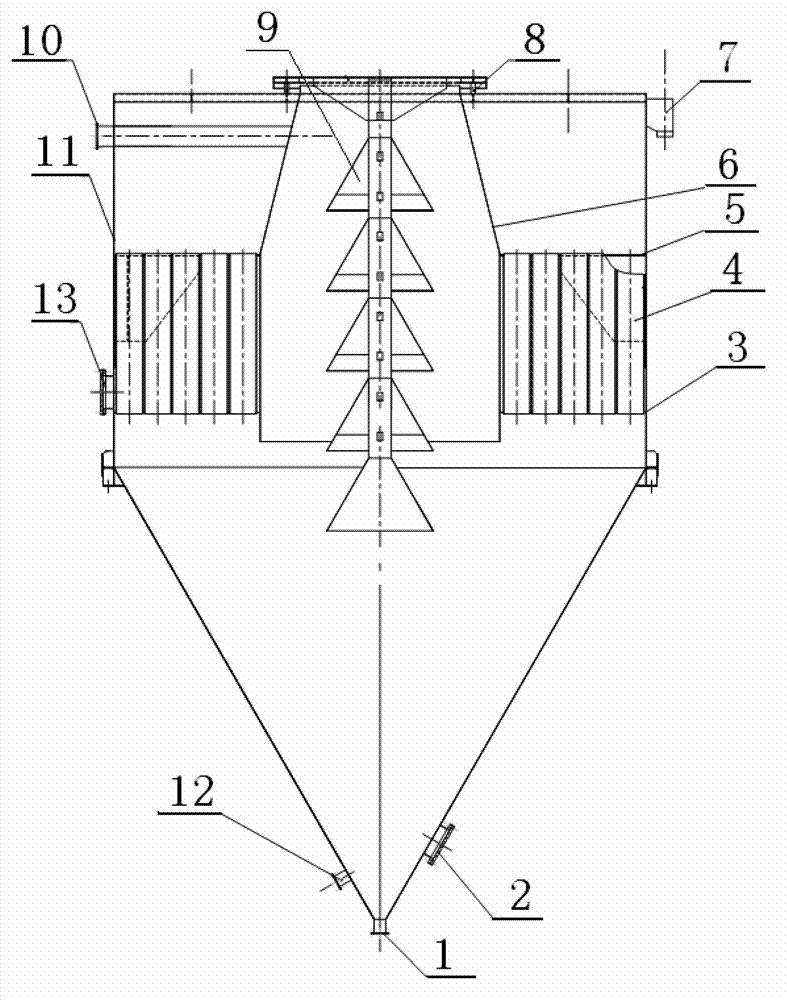

Settling separation device

A technology of sedimentation separation and equipment, applied in the direction of sedimentation tank, etc., can solve the problem of occupying the area of the factory area, and achieve the effect of reducing the floor space and improving the sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

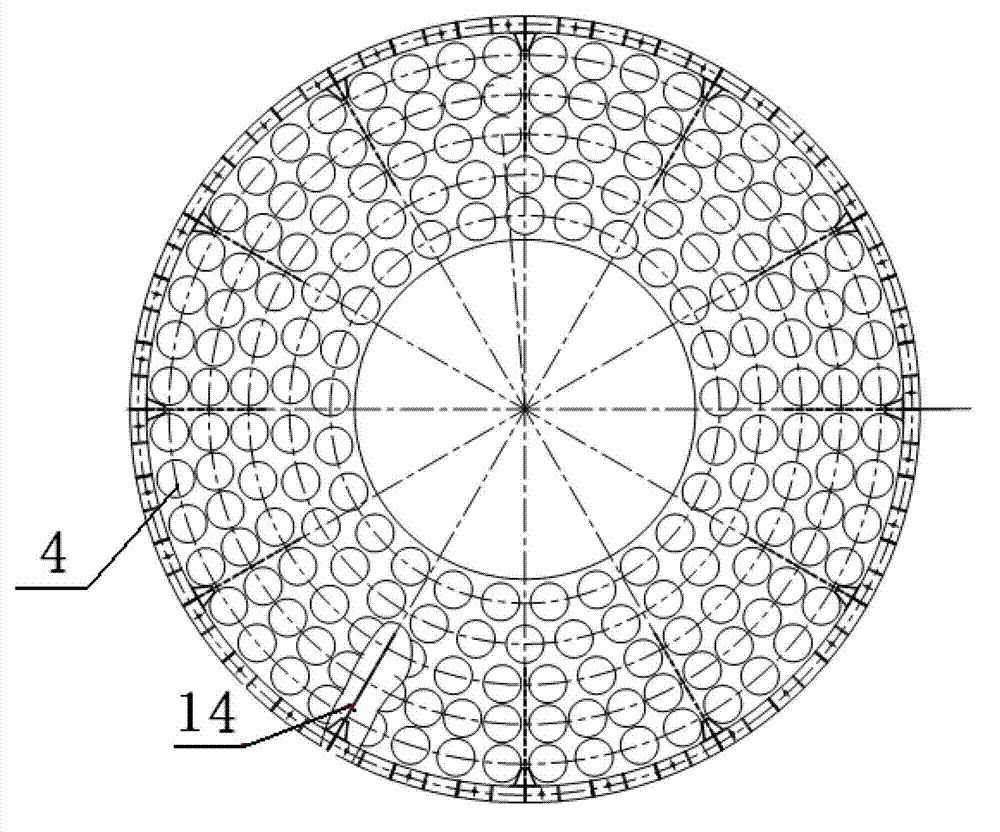

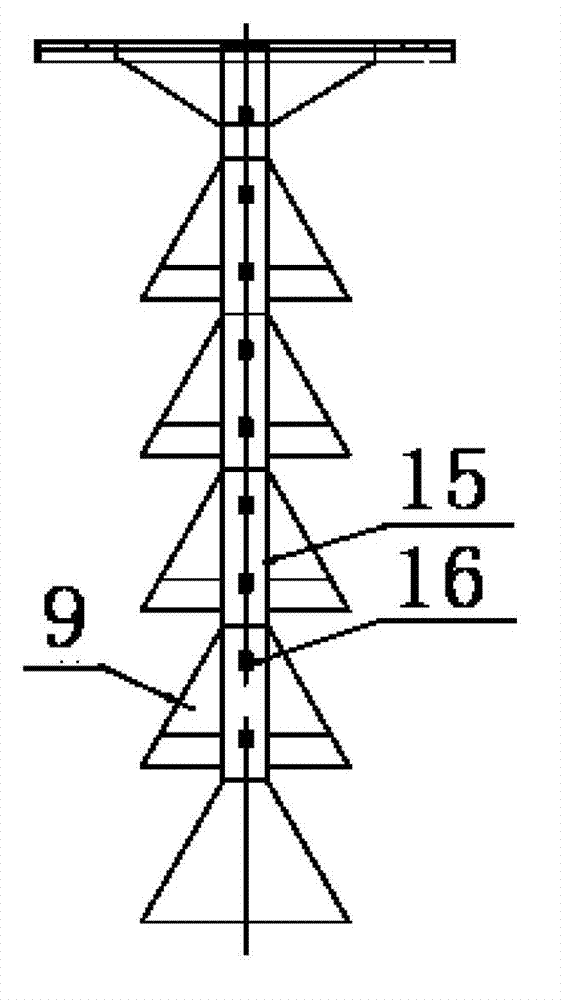

[0045] Different from Example 1, the ratio of the height of the cylinder to the cone height of the settling separation equipment disclosed in this example is 1:2, and 200 settling tubes with a length of 1 m and an inner diameter of 70 cm are worn between the two layers of partitions, namely Form 200 settlement channels. The umbrella used in this embodiment includes 10 conical barrels with openings facing downward fixed by steel pipes connected in series. The ratio of the maximum radius of the conical barrels to the cylinder radius of the feeding barrel is 1:5. A top cover for sealing the tank body is arranged above the tank body. The sedimentation and separation equipment disclosed in this embodiment can be effectively used for sedimentation of calcium silicate slag slurry in the production process of active calcium silicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com