Catalyst, LX catalytic oxidation method and antibiotic wastewater treatment method

A technology of antibiotic wastewater and catalytic oxidation, applied in the field of chemistry, to achieve the effect of reduced cost and operating cost and high efficiency

Active Publication Date: 2013-02-13

四川美峰环境治理有限责任公司

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

That is to say, it takes 20 days to determine the BOD in the first stage, which is difficult to achieve in actual work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0043] Catalyst C is sintered from 5kg nickel, 10kg cobalt and 20kg silica.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Login to View More

Abstract

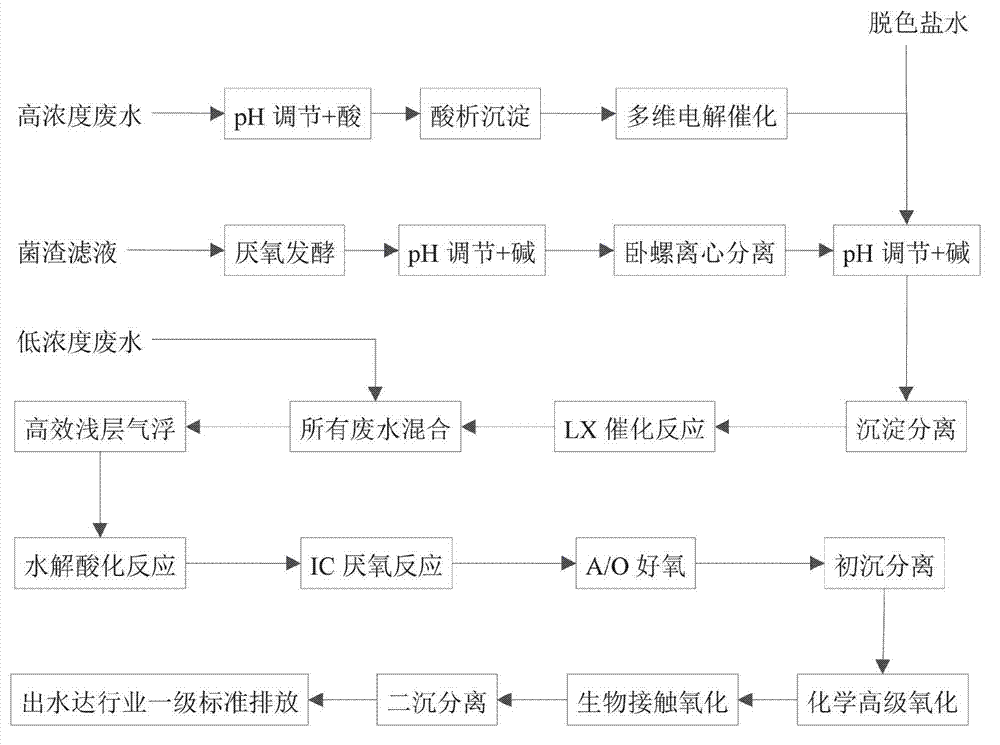

The invention discloses a catalyst, an LX catalytic oxidation method and an antibiotic wastewater treatment method. Nickel, cobalt and silica are sintered in accordance with the proportion to form the catalyst. Hypochlorous acid or hypochlorite and the catalyst are added to organic wastewater, and the catalytic reaction is conducted. The wastewater of high concentration is subjected to pretreatment through a multidimensional electric catalytic oxidation method, the fungi residue filtrate is subjected to pretreatment through anaerobic digestion, the mixing liquid of the wastewater of high concentration and the fungi residue filtrate which are obtained in the above step is treated through the LX efficient catalytic oxidation method, and the comprehensive wastewater obtained in the above step is treated through a normal process. The catalyst, the LX catalytic oxidation method and the antibiotic wastewater treatment method have the advantages that under the action of the catalyst, organic matters and harmless matters such as NO2, CO2, H2O and N2 which are formed through catalytic oxidation of toxicants and toxic elements which contain N, CN and S in the wastewater are discharged. By the aid of the method, the efficient in antibiotic wastewater treatment and in erythrocin wastewater treatment is high, and the cost and the operation cost are reduced greatly.

Description

technical field [0001] The invention belongs to the field of chemistry, and in particular relates to a catalyst, a chemical reaction using the catalyst and a wastewater treatment method using the reaction. Background technique [0002] With the rapid development of the pharmaceutical industry in recent years, pharmaceutical wastewater has become one of the main sources of environmental pollution. Pharmaceutical industry wastewater mainly includes four categories: antibiotic production wastewater, synthetic drug production wastewater, Chinese patent medicine production wastewater, washing water and flushing wastewater in the production process of various preparations. Due to the wide variety of drugs, a variety of raw materials are used in the production process, and the production process is relatively complicated. Therefore, the composition of the wastewater is also very complicated, and its treatment is also difficult. Among them, the treatment of erythromycin production w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/755C02F1/72C02F9/14C02F101/38C02F101/34

Inventor 宋岱峰胡海蓉

Owner 四川美峰环境治理有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com