Drug pulverizer

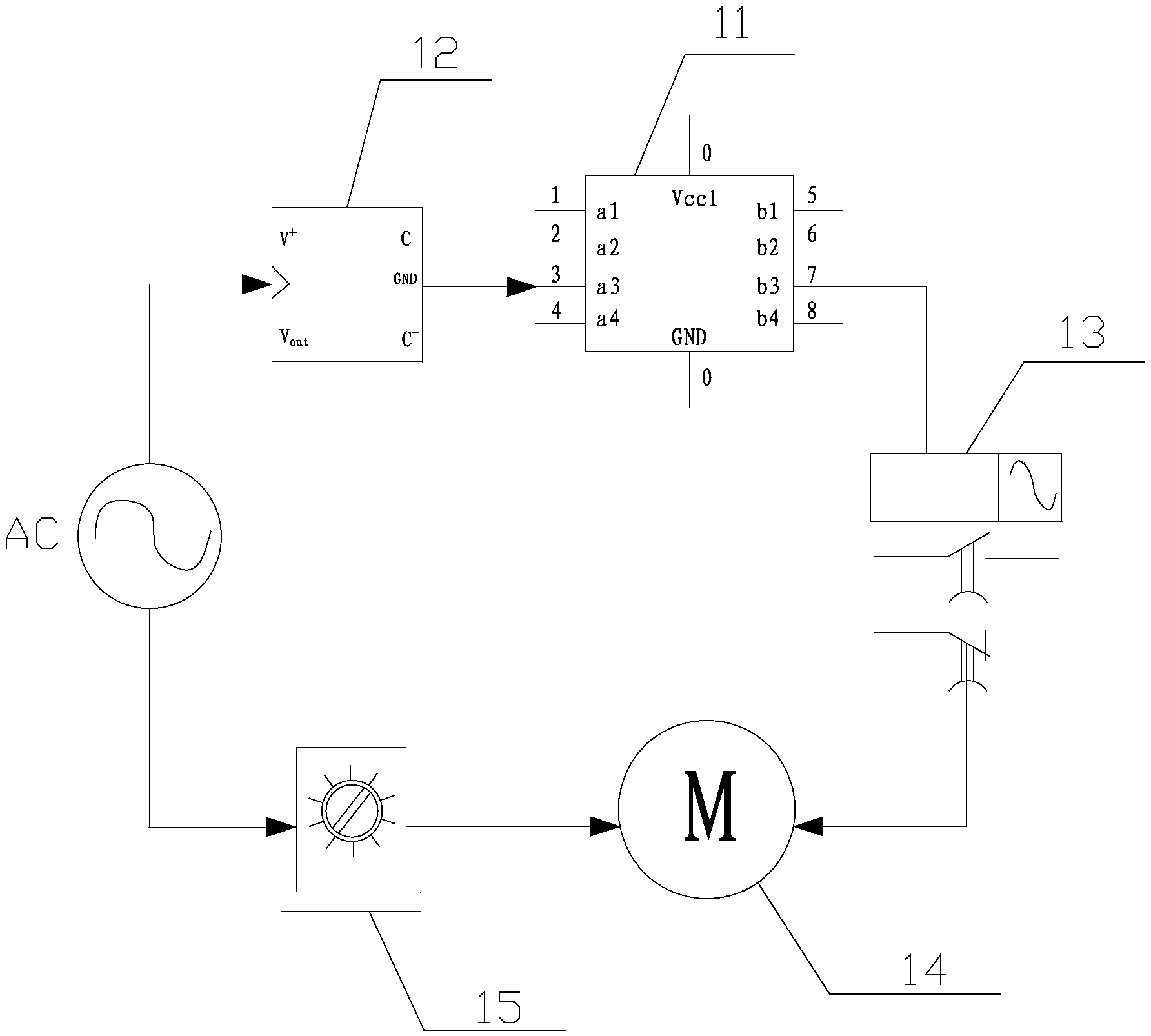

A pulverizer and drug technology, applied in the field of medical devices, can solve the problems of increasing impurities, pollution, drug dosage changes, etc., and achieve the effects of improving work efficiency, ensuring environmental quality, and high crushing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

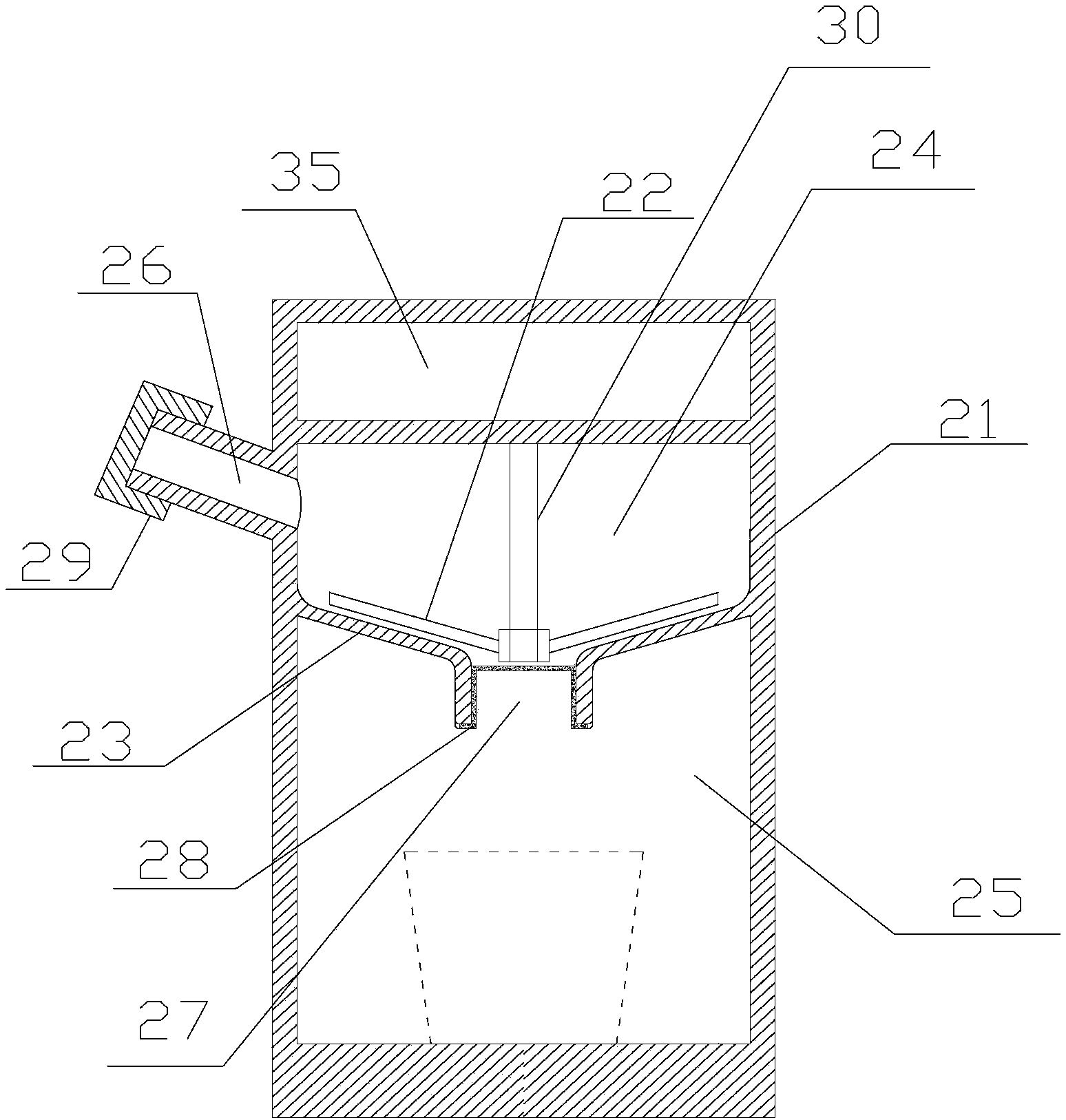

[0037] Such as figure 2 As shown, a drug grinder includes a casing 21, a rotating shaft 30 suspended inside the casing 21, at least one stage of crushing blade 22 located on the rotating shaft 30, and an electric control device for driving the crushing blade 22 to run; the inside of the casing 21 is provided There is a baffle 23, and the first-level pulverizing blade at the bottom is arranged near the baffle 23, and it is convenient to crush the tablets at the bottom by making the pulverizing blade and the baffle close to each other, so as to ensure the thoroughness of the crushing of the tablets. Among them, the crushing blade can be one or more stages to improve the crushing efficiency.

[0038] The baffle plate 23 divides the shell 21 into a feed chamber 24 and a discharge chamber 25. The shell 21 is provided with a feed port 26 for feeding into the feed chamber 24. The baffle plate 23 is provided with a through hole extending downward. A discharge port 27 is formed, and ...

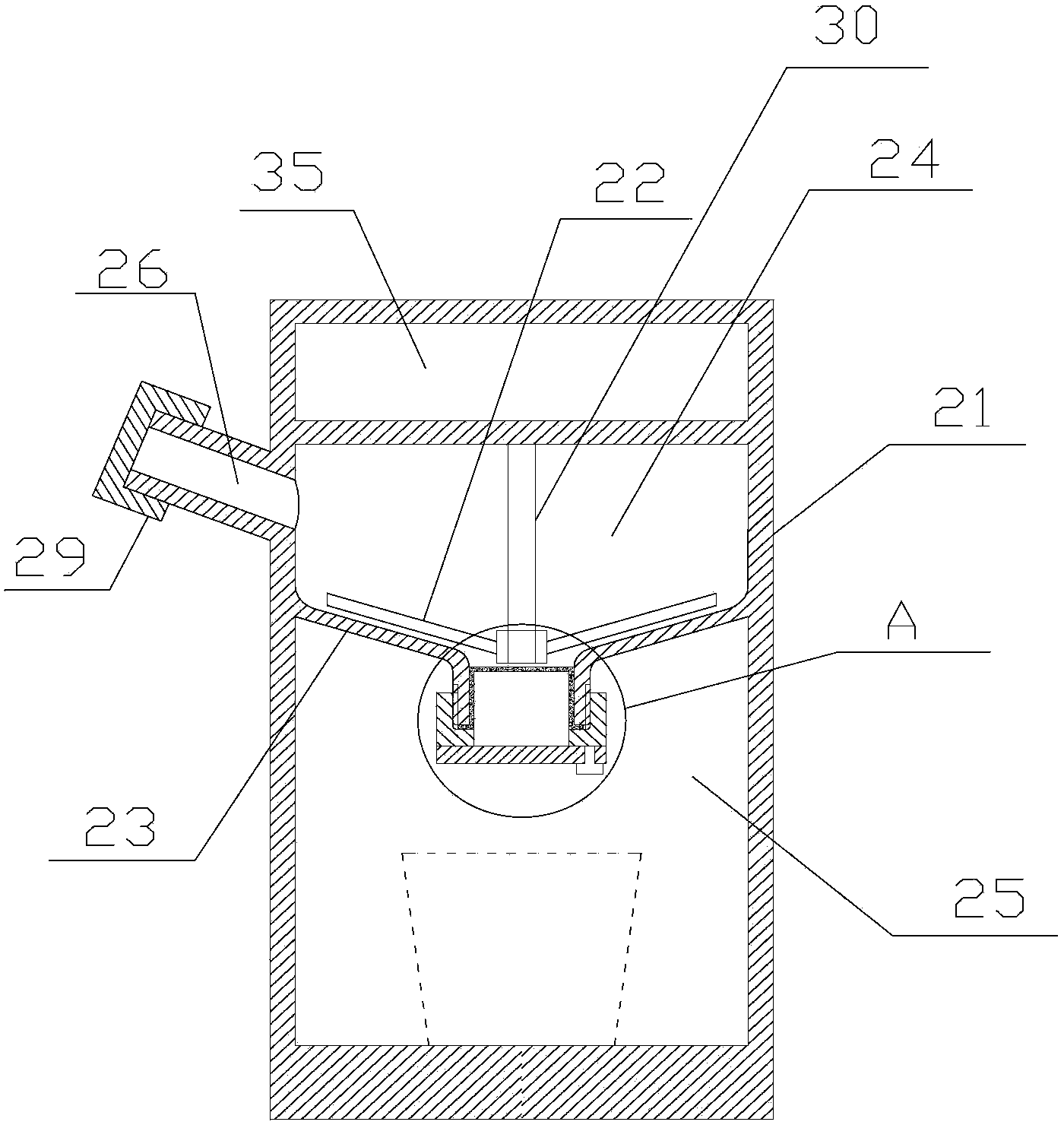

Embodiment 2

[0047] The rest is the same as that of Embodiment 1, except that a cover 31 is provided at the lower end of the outlet 27 , and a storage bin 32 is formed between the cover 31 and the filter screen 28 . A cover 33 is disposed between the cover 31 and the discharge port 27 , the cover 33 is detachably connected to the discharge port 27 , and the cover 31 is detachably connected to the cover 33 . By setting the cover so that the cover is fixed on the output end of the discharge port, the cover is connected to the outside of the discharge port by threads, and the cover 31 is arranged on the cover through the rotation of the pin shaft. By rotating the cover, it can realize The opening and closing of the discharge port is convenient for the medicine to be poured out after crushing, so as to avoid dust flying out, loss of medicine and influence on environmental quality.

[0048] In addition to fixing the cover on the cover through a pin shaft, one end of the cover can be hinged to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com