Vacuum suction high-speed intelligent automatic screw fastening mechanism

A fastening mechanism and screw technology, which is applied in the field of high-speed intelligent automatic screw fastening mechanism platform, can solve the problems that the product quality cannot be guaranteed, the workload of manual operation is large, and the labor intensity is high, and it achieves a small footprint, Simplification of work and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The vacuum suction type high-speed intelligent automatic locking screw mechanism will be described in detail below in conjunction with the embodiments.

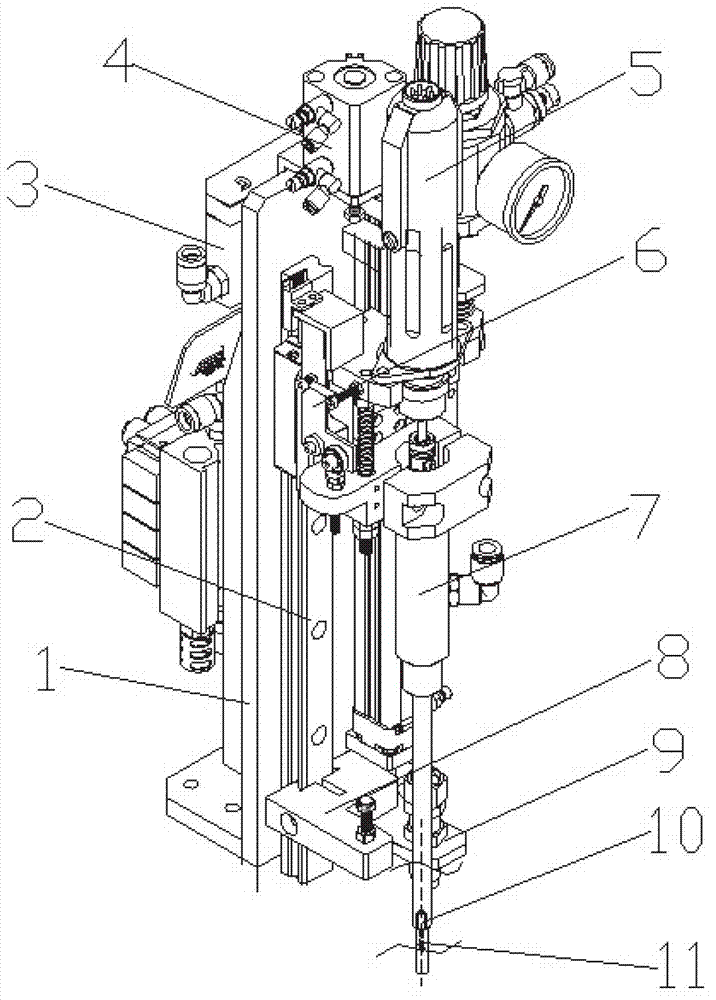

[0016] Such as figure 1 As shown, the mechanism is composed of a screw suction device and a screw fastening device. In the screw suction device, the screw cylinder 4 pushes the vacuum suction tube 7 to move downward, and the vacuum generator 3 acts to suck the screw, realizing the way of suction nailing, and the screw is tightened. Fixing device then waits for screw to be sucked, and screwdriver drives cylinder action to make screwdriver head 11 rotate downwards, carries out locking nail, detects floating lock by photoelectric detection device 6, realizes cycle operation. The electric screwdriver 5 is connected to the screwdriver head 11 through the drive shaft 10, and the electric screwdriver 5 is driven to rotate by the motor.

[0017] The guide rail 2 is fixed on the frame 1, the screw fastening device is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com