Four-freedom-degree single-action platform parallel mechanism capable of achieving motion of selective compliance assembly robot arm (SCARA)

A degree of freedom, moving platform technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex kinematics, unfavorable production efficiency, improvement and other problems, achieve high-speed and high-acceleration dynamic response characteristics, and relatively simple kinematics , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

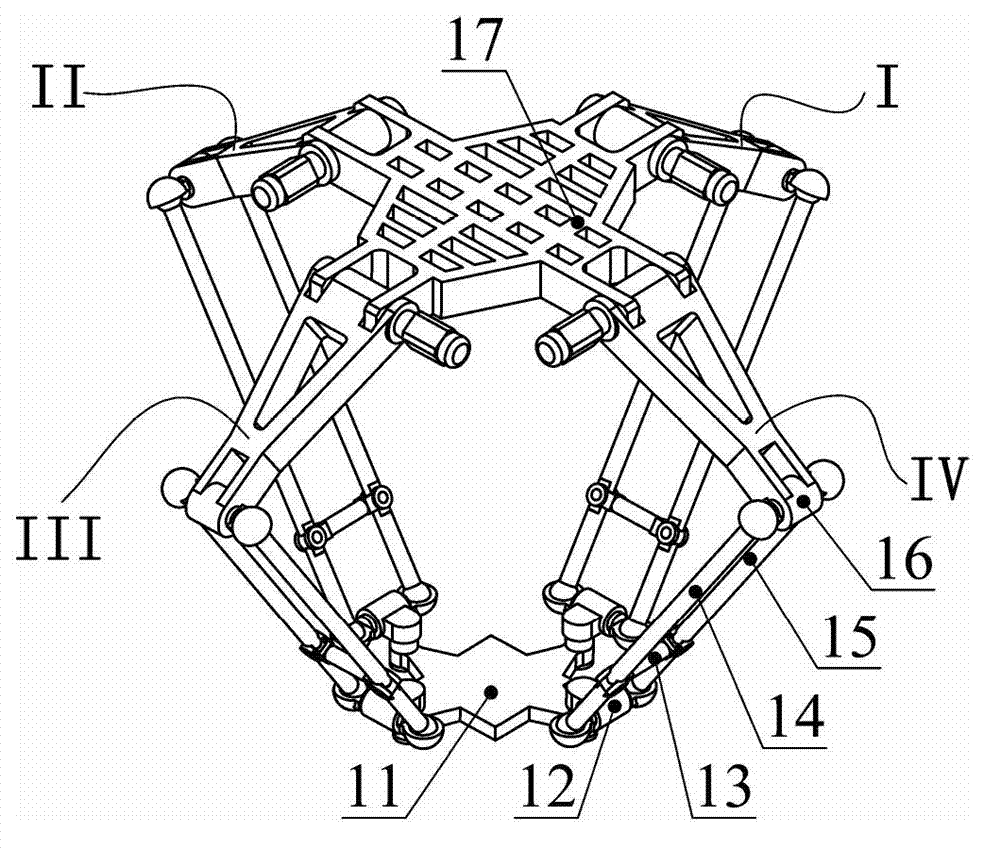

[0017] The structure of a four-degree-of-freedom single-platform parallel mechanism that can realize SCARA motion in this embodiment is as follows: figure 1 As shown, it includes a fixed platform 17, a moving platform 11, and the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV, and the four branch chains are respectively connected to the fixed platform 17 and the moving platform 11, and form a space closed-loop mechanism with the fixed platform 17 and the moving platform 11.

[0018] The structures of the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV are exactly the same. In the figure, the fourth branch chain IV is taken as an example, including: a driving arm 16, a left connecting rod 14 , right connecting rod 15, support rod 13, connector 12 and kinematic pair. There are seven kinematic pairs, one is the revolving pair R connected between the fixed plat...

Embodiment 2

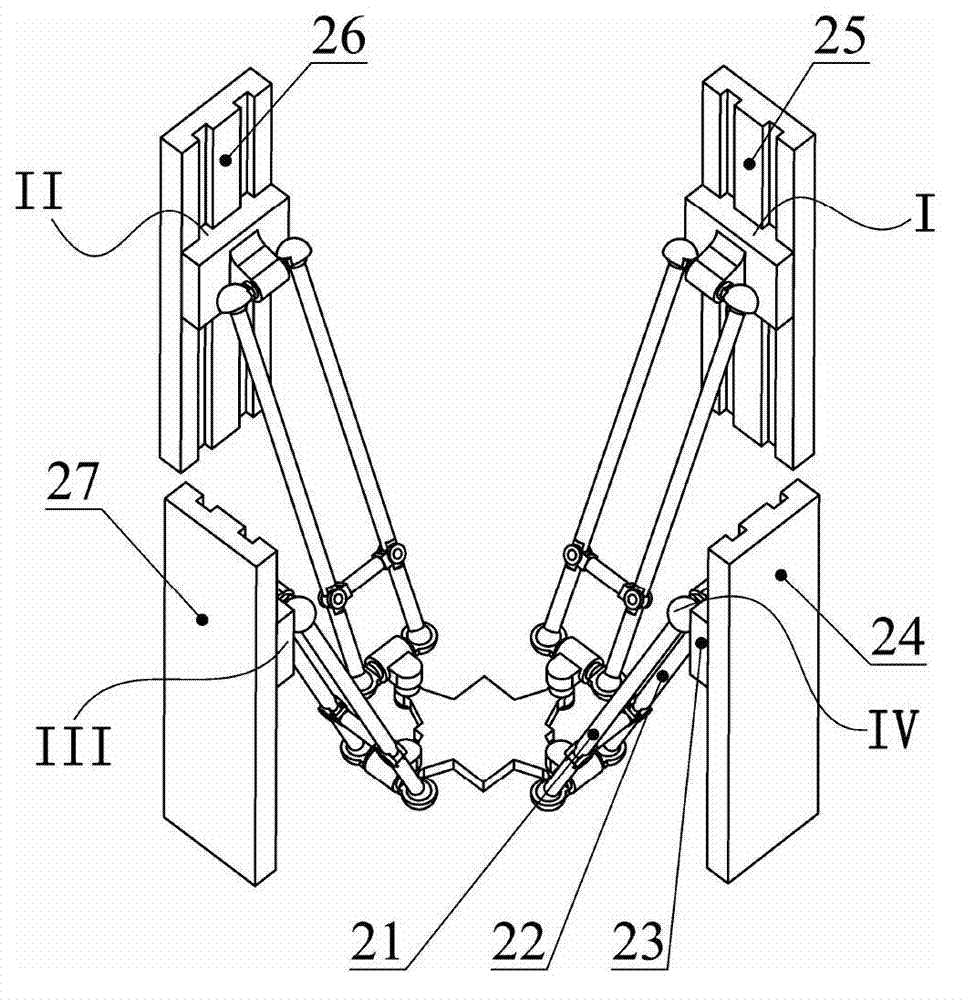

[0021] The structure of a four-degree-of-freedom single-platform parallel mechanism that can realize SCARA motion in this embodiment is as follows: figure 2 As shown, similar to Example 1, it also includes the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV with the same structure. The difference between this embodiment and the first embodiment is that the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV all adopt the driving form of the active drive of the moving pair. Embodied in the specific structure: the slider 23 of its fourth branch chain IV is connected with the left connecting rod 21 through a ball joint, the slider 23 is connected with the right connecting rod 22 through a ball joint, and the slider 23 is connected with the fixed platform 24 is connected by a mobile pair and the mobile pair is actively driven. In this embodiment, the fixed platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com