An ultrasonic vibration rotary digging device

A technology of ultrasonic vibration and internal rotation, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problem of difficult to obtain sapphire rods at one time, and achieve the effect of low processing cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

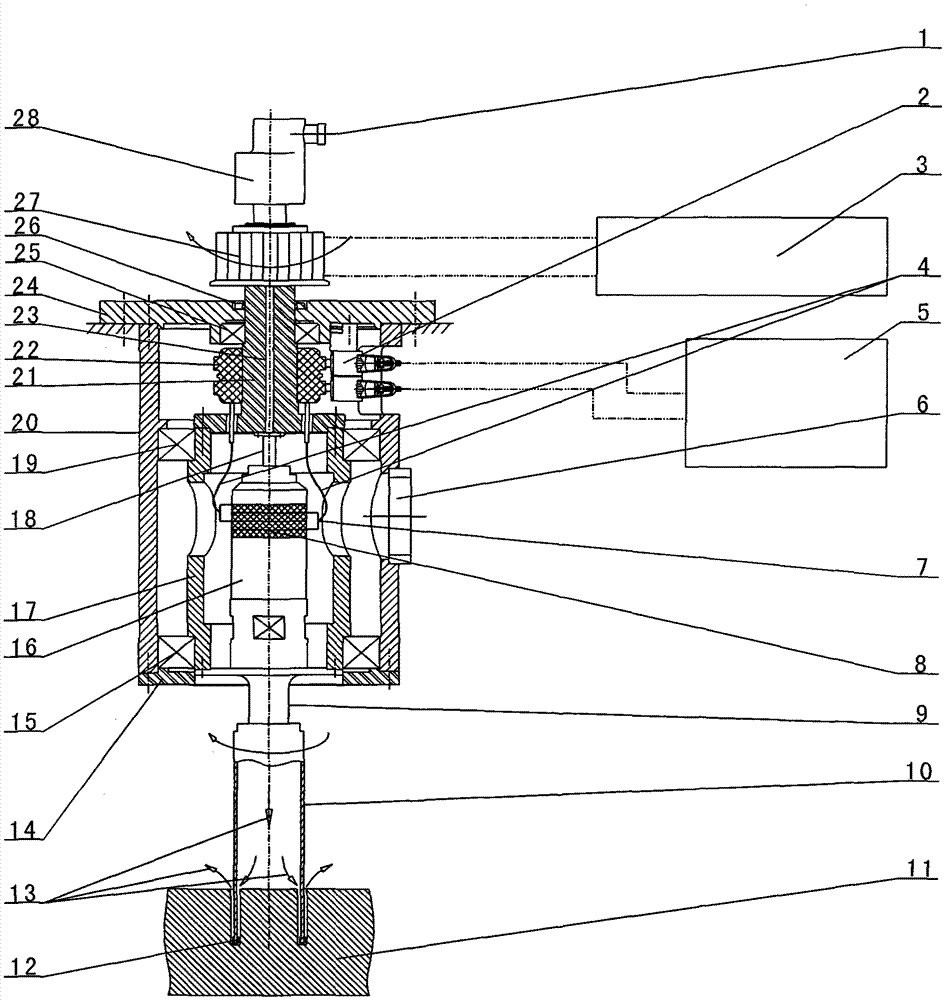

[0023] combined with figure 1 The ultrasonic vibration rotary digging device described in includes a transmission shaft 21, a power wheel 27, an upper cover 24, a slip ring 22, an ultrasonic generator 5, an inner rotating sleeve 17, a transducer 16, an outer sleeve 20, The horn 9 and the digging drill 10, the middle part of the transmission shaft 21 is fixedly sleeved with the collector ring 22, and the collector ring 22 is slidably connected with the carbon brush 2 fixed on the outer sleeve 20, and the carbon brush 2 is externally connected with an ultrasonic generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com