Feeding clearance control method and device of seamless welding machine

A technology of seamless welding and control method, which is applied in the field of plastic molding or connection, can solve the problems of low investment, large welding bump, excessive redundancy, etc., and achieve the effects of high weld strength, material saving, and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment.

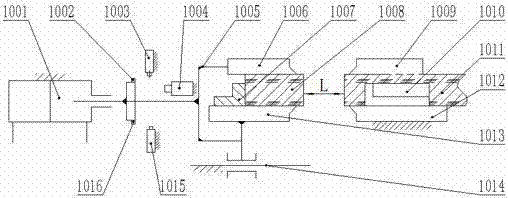

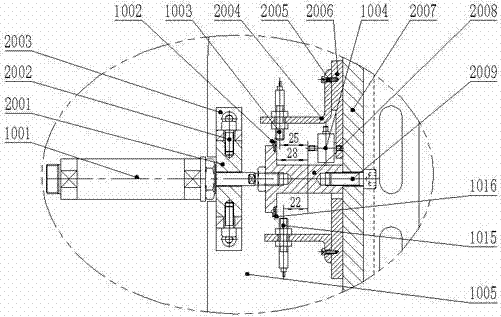

[0020] See attached figure 1 , weldment one 1008 is positioned and clamped by rear lower clamp 1013, rear upper clamp 1006 and rear stopper 1007, and is jointly driven by rear seat 1005 to move left and right; weldment two 1011 is formed by front lower clamp 1012 and front upper clamp 1009 and front block 1010 are positioned and clamped, and are fixed together on the frame. The distance L between the welding surface of the weldment 1007 and the second weldment 1011 needs to be strictly controlled during the positioning, melting and docking stages, so as to reduce the weld spatula and realize seamless welding under the premise of satisfying the welding strength. It works as follows.

[0021] (1) Positioning clearance control: the thrust cylinder 1001 drives the induction plate 1002 to push the rear seat 1005 to move forward together, the induction plate 1002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com