Manufacturing method of wheel-shaped part

A manufacturing method and component technology, which is applied in the field of manufacturing small wheel-shaped components, can solve the problems of low joint strength, short service life, small joint area, etc., and achieve the effect of improving joint strength and increasing joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: A kind of manufacturing method of wheel-shaped component

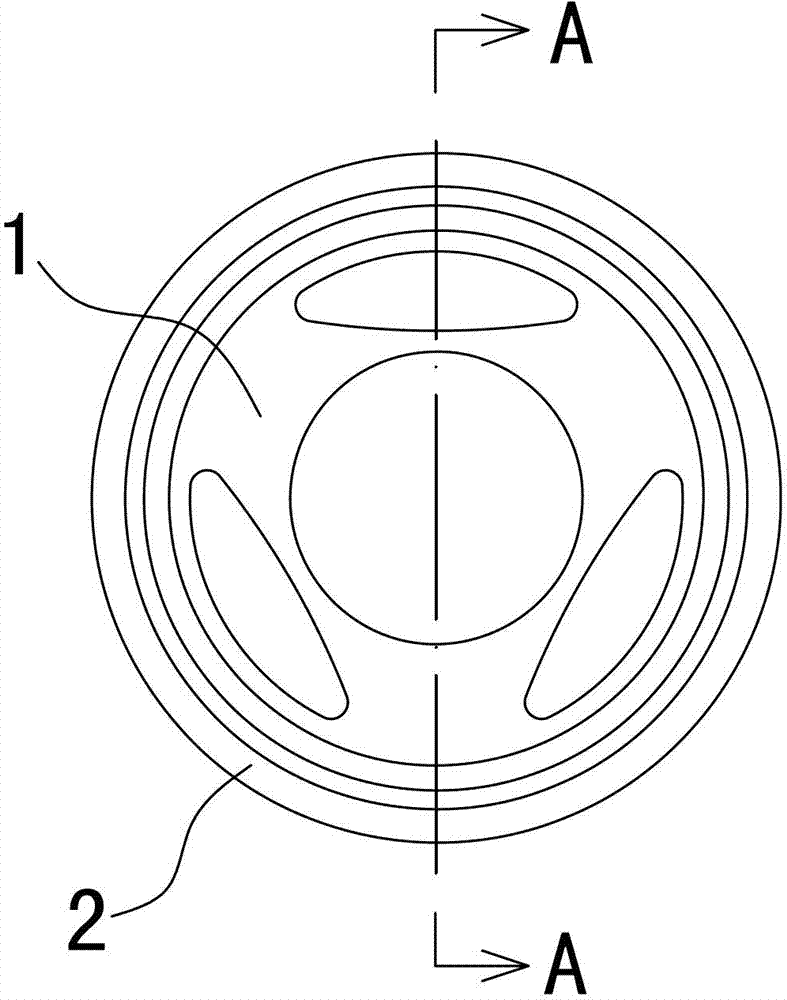

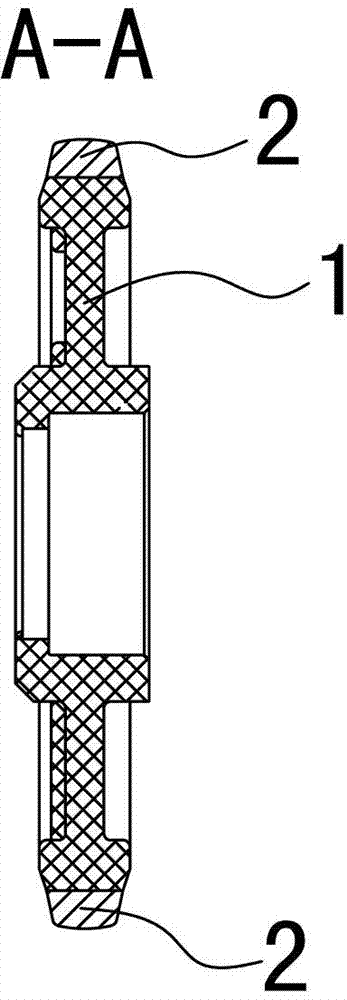

[0034] See attached figure 1 And attached figure 2 As shown, the wheel-shaped part includes a plastic wheel 1, and the circumference of the plastic wheel 1 is D 1 , the plastic wheel 1 is provided with a circle of rubber belt 2 along its circumference, and the manufacture of the wheel-shaped part consists of the following steps:

[0035] Step 1: Prepare Materials

[0036] The general-purpose compound rubber on the market is mixed into rubber, and the general-purpose plastic particles on the market are processed into plastic particles with a diameter of 0.07 mm.

[0037] The rubber compound refers to the uncrosslinked and fluid rubber material mixed with the compounding ingredients in the block, granular and powder raw rubber. It is the blank for making rubber products, that is, the semi-finished product. When mixing rubber, no temperature is added to make it incompletely formed. The shape of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com